Polycrystalline silicon forming method, TFT (thin film transistor) array substrate manufacturing method and display device

An array substrate, polysilicon technology, applied in semiconductor/solid-state device manufacturing, transistors, instruments, etc., can solve the problems of easy early turn-on and hump, and achieve the effect of avoiding hump phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

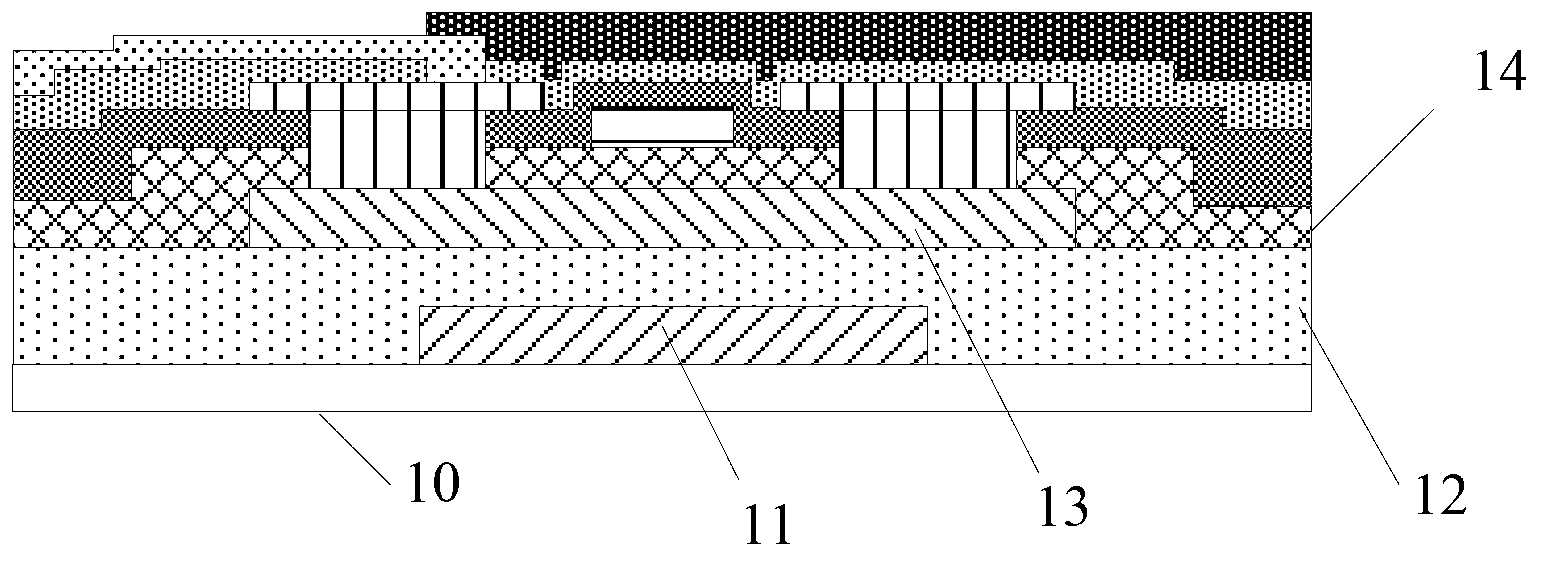

[0028] The invention provides a method for forming polysilicon in a TFT array substrate. In the method, a special step structure is formed at the position of the light-shielding layer corresponding to the TFT channel region, and the crystallization of the subsequently formed polysilicon layer is not saturated at the corresponding position, that is, the obtained The crystal failure at the edge of the TFT channel avoids hump phenomenon.

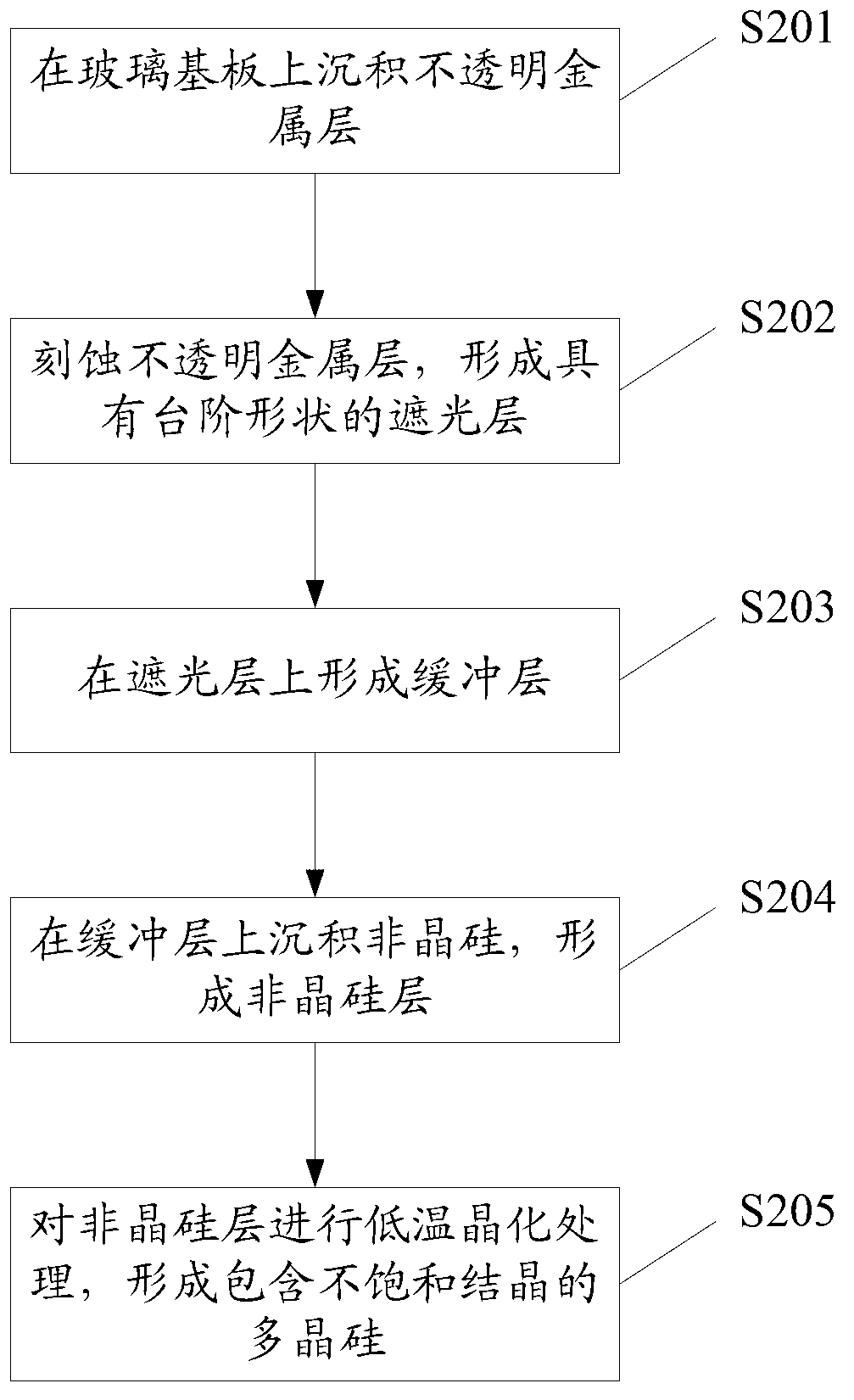

[0029] Embodiment 1 of the present invention provides a method for forming polysilicon in a TFT array substrate. The schematic flow diagram of the method is shown in figure 2 shown.

[0030] Step S201 : Depositing an opaque metal layer on the glass substrate 10 .

[0031] Specifically, firstly, the glass substrate 10 is cleaned through an initial cleaning process, and an opaque metal of a certain thickness is deposited on the cleaned glass substrate 10 by magnetron sputtering (PVD) method.

[0032] Step S202: Etching the opaque metal layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com