Retaining device for substrates and method for coating a substrate

A retainer and coating technology, which is used in semiconductor/solid-state device manufacturing, coating, sputtering, etc., and can solve the problems of insufficient grade purity and inability to exclude particles from falling on the surface of the substrate to be coated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

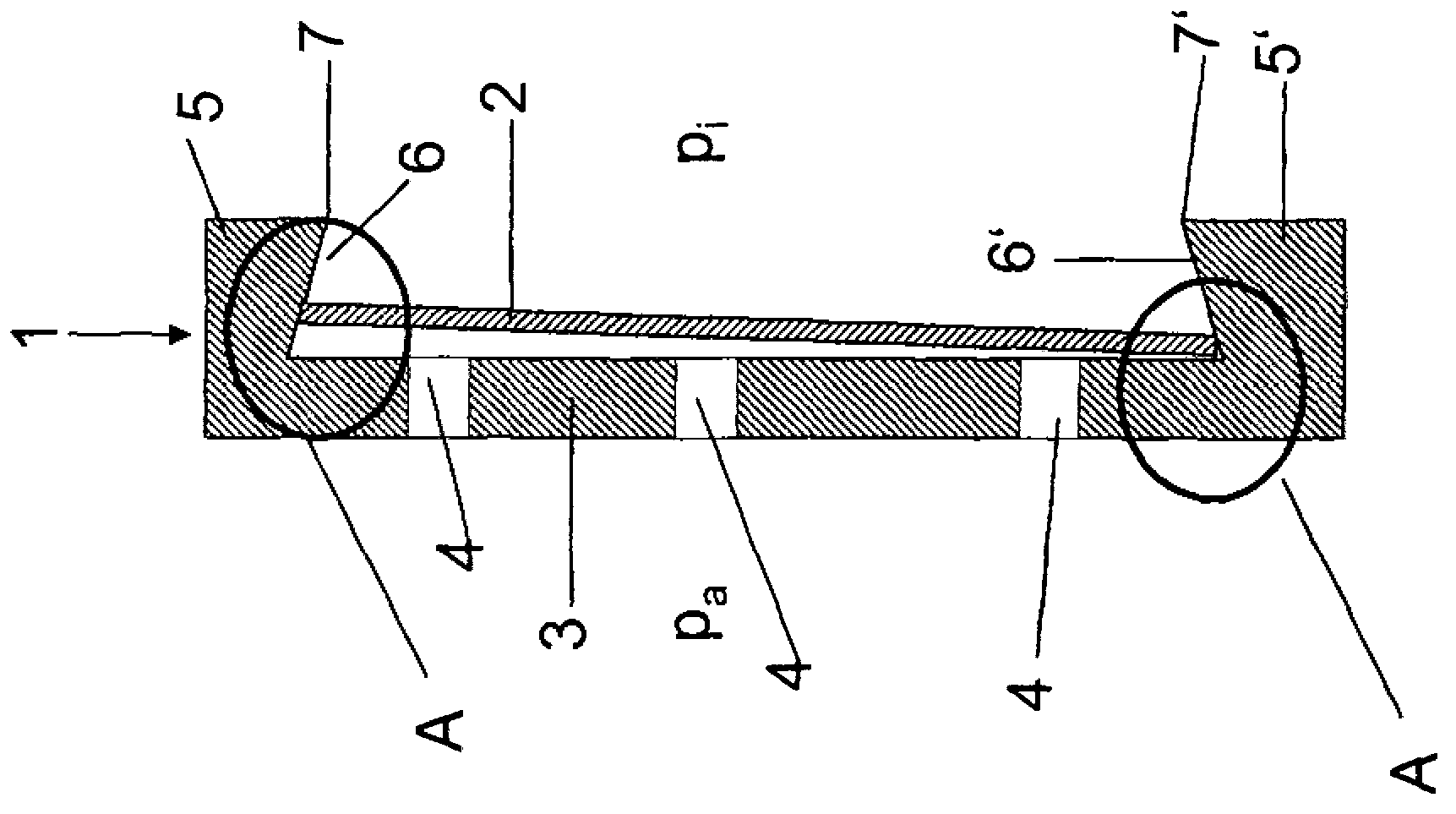

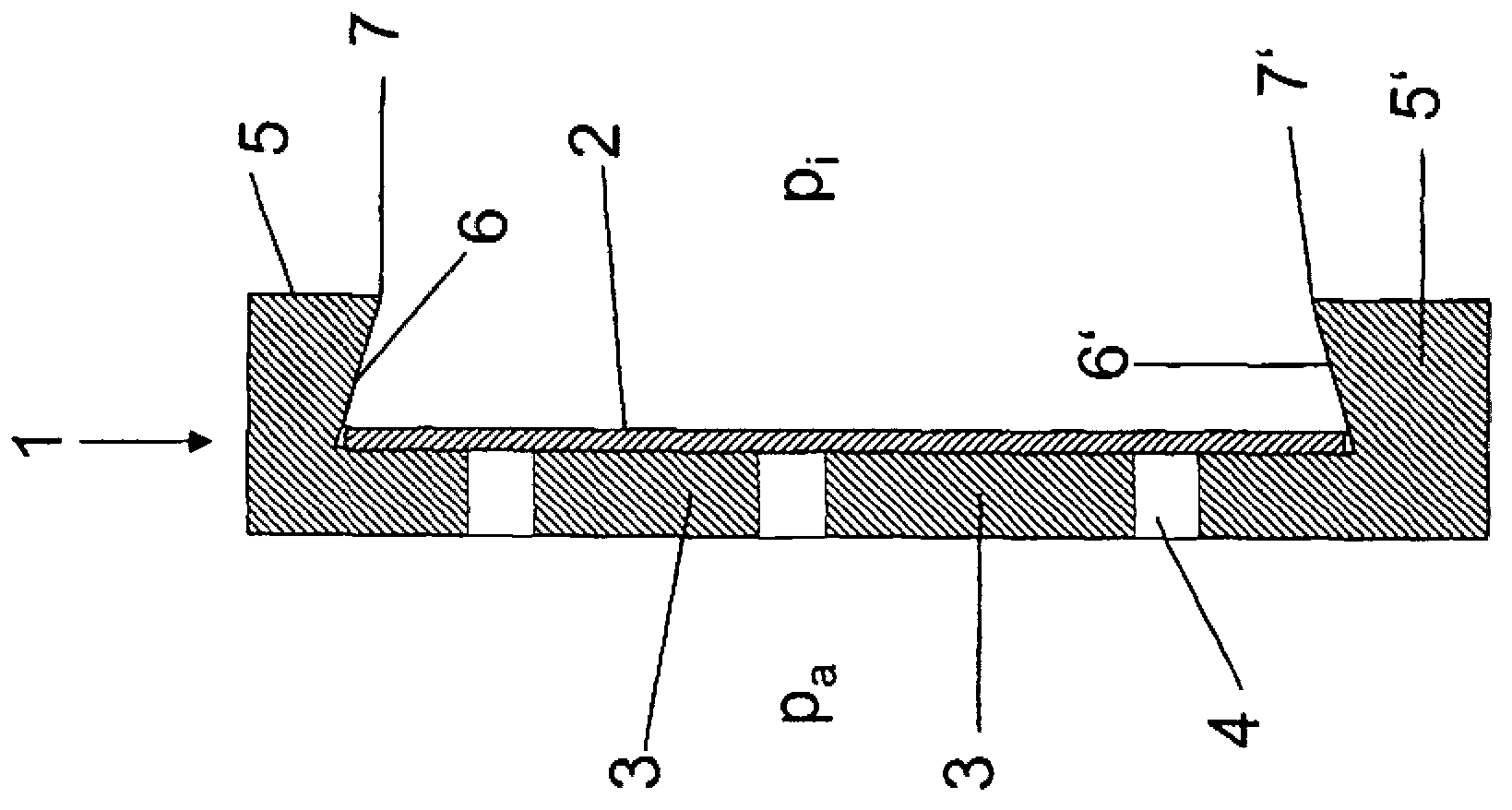

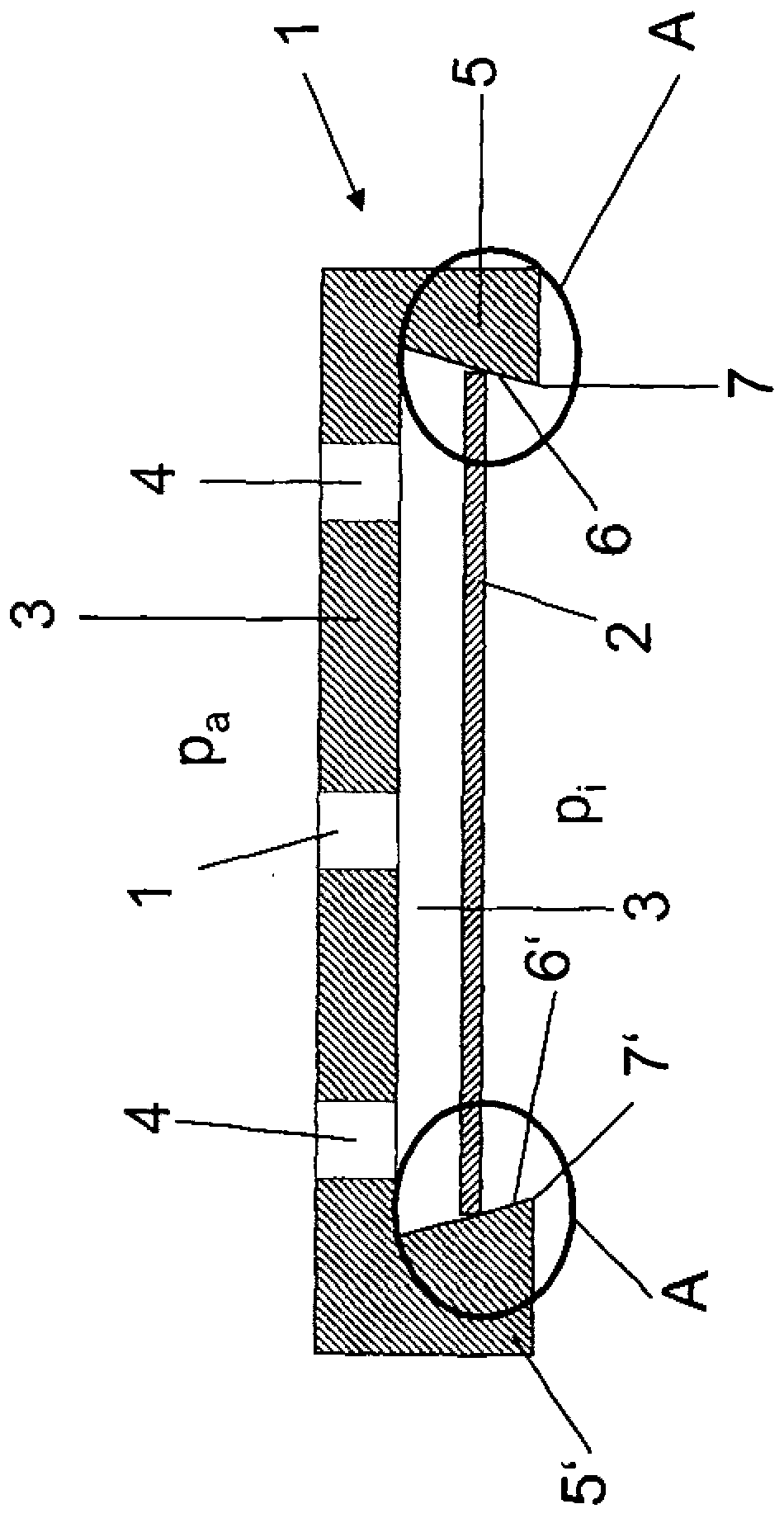

[0046] Figure 1 shows a retainer 1 according to the invention placed vertically, first before substrate suction ( Figure 1a ), followed by basal inhalation ( Figure 1b ). Thus, the retainer 1 comprises a support device 3 , which may also be referred to as a base bracket, and three apertures 4 positioned continuously through the support device 3 in the form of through holes in the section shown. Two arms (arm 5 and arm 5 ′) integrally formed with the support device 3 are flanked on both sides of the support device 3 . Therefore, the arm 5 and the arm 5' respectively have an inner wall 6 and an inner wall 6', and the inner wall 6 and the inner wall 6' have chamfered structures. In the case of the device 1 shown here, the angle at which the walls 6 , 6 ′ each surround the support surface of the substrate carrier 3 for the substrate 2 is, for example, approximately 75°. However, larger or smaller angles are also possible. Likewise, the angles of the arms 5 and 5' can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com