Light full-plastic wheel carrier

A wheel frame and light-weight technology, which is applied in vehicle rescue, medical transportation, transportation and packaging, etc. It can solve the problems of increased inconvenience for medical staff and patients, affecting the work efficiency of doctors, environmental pollution and other problems, and achieves simple structure and light weight , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

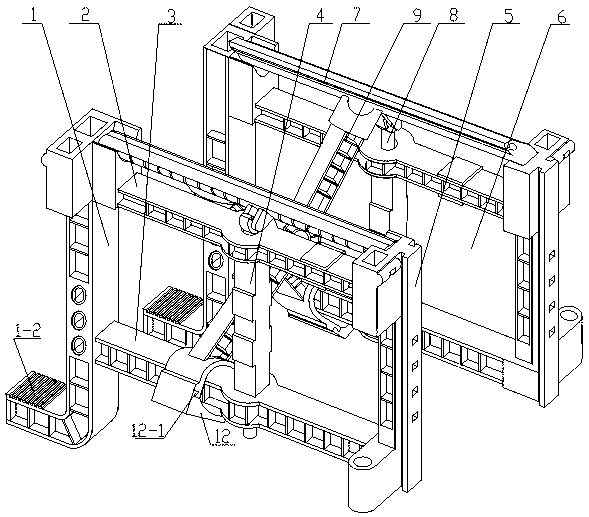

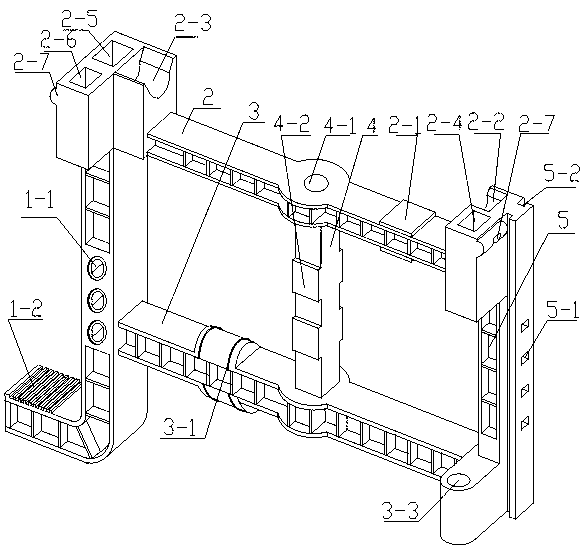

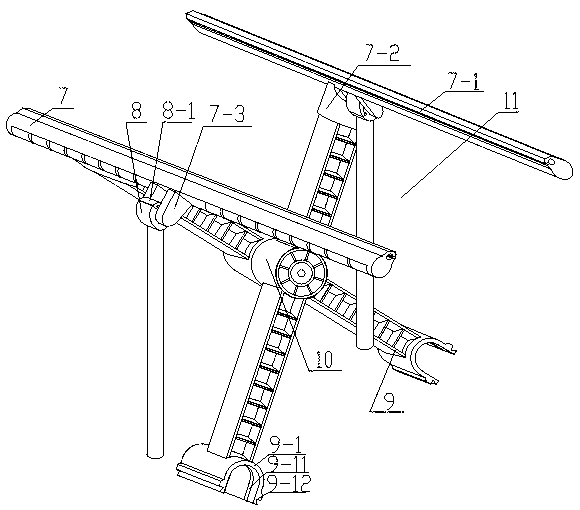

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] The half frame 6 is formed by injection molding of upper and lower cross bars, front, middle and rear straight bars into a closed shape.

[0012] Upper and lower cross bars 2,3, front and rear straight bars 5,1, their cross sections are all H-shaped with reinforcing ribs, and the middle straight bar 4 cross section is a rectangle with balance bar perforation 4-1 in the middle.

[0013] There are respectively a first platform 2-1 and two second platforms 4-2 on the upper cross bar 2 and the middle straight bar 4 to facilitate the installation of the brake components. There are three mounting holes 1-1 in different installation positions on the rear straight bar 1. 1 and rear pedal 1-2.

[0014] There are more than two protruding ring ribs 3-1 on the corresponding positions on the lower cross bar 3 peripherals, which are convenient to be connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com