Vanadate nanofiber photocatalyst and preparation method thereof

A nanofiber, photocatalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult to use electrospinning, achieve good visible light catalytic degradation ability, rapid separation, The effect of narrow bandgap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

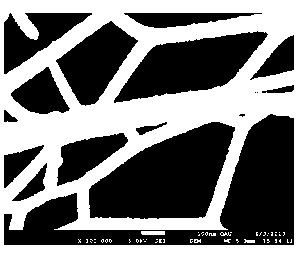

[0021] (1) Dissolve 1 mmol of bismuth 2-ethylhexanoate and 0.5 g of polyvinylpyrrolidone in 5 ml of absolute ethanol in sequence under stirring to obtain solution A; dissolve 1 mmol of vanadyl acetylacetonate in 5 ml of absolute ethanol to obtain B solution; add solution B dropwise to solution A, stir well for 4 hours to prepare spinning solution.

[0022] (2) Electrospin the above spinning solution into filaments through an electrospinning device to obtain a composite nanofiber mat of bismuth vanadate and polyvinylpyrrolidone; the specific process is as follows:

[0023] Inhale the spinning solution into the syringe (with a capacity of 5-20ml), the advancing speed of the syringe is controlled by a micro constant flow pump, the needle of the syringe (metal material, inner diameter 0.6mm-1.2mm) faces down and is connected to the positive pole of the high-voltage power supply, and the fiber collection plate (Metal sheet, square with side length of 400mm-600mm) placed horizontall...

Embodiment 2

[0027] (1) Dissolve 3mmol of silver nitrate and 0.75g of polyvinylpyrrolidone in 5ml of absolute ethanol in sequence under stirring to obtain solution A; dissolve 1mmol of vanadium triethoxyoxide in 5ml of absolute ethanol to obtain solution B; Liquid B was added dropwise to liquid A, and the spinning solution was prepared by fully stirring for 6 hours.

[0028] (2) Electrospin the above spinning solution into filaments through an electrospinning device to obtain a composite nanofiber mat containing silver vanadate and polyvinylpyrrolidone; the specific process is the same as that in Example 1.

[0029] (3) The above-mentioned fiber mat is placed in the air to age for 10 hours, and then calcined at 500-600 ° C in an air atmosphere for 5 hours to remove polyvinylpyrrolidone to obtain monoclinic silver vanadate (Ag vanadate). 3 VO 4 ) nanofiber photocatalysts with fiber diameters ranging from 50 nm to 70 nm.

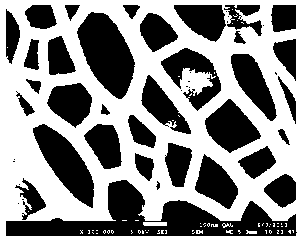

[0030] figure 2 The micrograph of the silver vanadate nanofiber p...

Embodiment 3

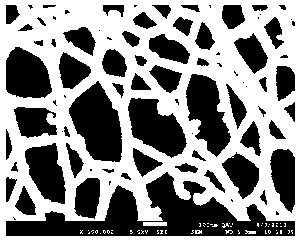

[0032] (1) Dissolve 0.5 mmol of ammonium bismuth citrate, 1.5 mmol of silver nitrate and 1 g of polyvinylpyrrolidone in 5 ml of absolute ethanol in sequence under stirring to obtain liquid A; dissolve 1 mmol of the organic vanadium salt vanadyl triisopropoxide in 5 ml of In absolute ethanol, liquid B was obtained; liquid B was added dropwise to liquid A, and the spinning solution was prepared by fully stirring for 8 hours.

[0033](2) Electrospin the above spinning solution into filaments through an electrospinning device to obtain a nanofiber mat containing bismuth vanadate and silver vanadate composites and polyvinylpyrrolidone; the specific process is the same as that of Example 1.

[0034] (3) The above-mentioned fiber mat is placed in the air to age for 16 hours, and then calcined for 6 hours at 500-600 ° C in an air atmosphere to remove polyvinylpyrrolidone to obtain monoclinic bismuth vanadate and silver vanadate (Ag vanadate). 1.5 Bi 0.5 VO 4 ) composite nanofiber ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com