Conveying technology for iron tailing paste

A paste and process technology, applied in the field of iron tailings paste conveying process, can solve the problem of high investment in diaphragm pumps, achieve the effects of improving conveying efficiency, eliminating potential safety hazards, and reducing equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

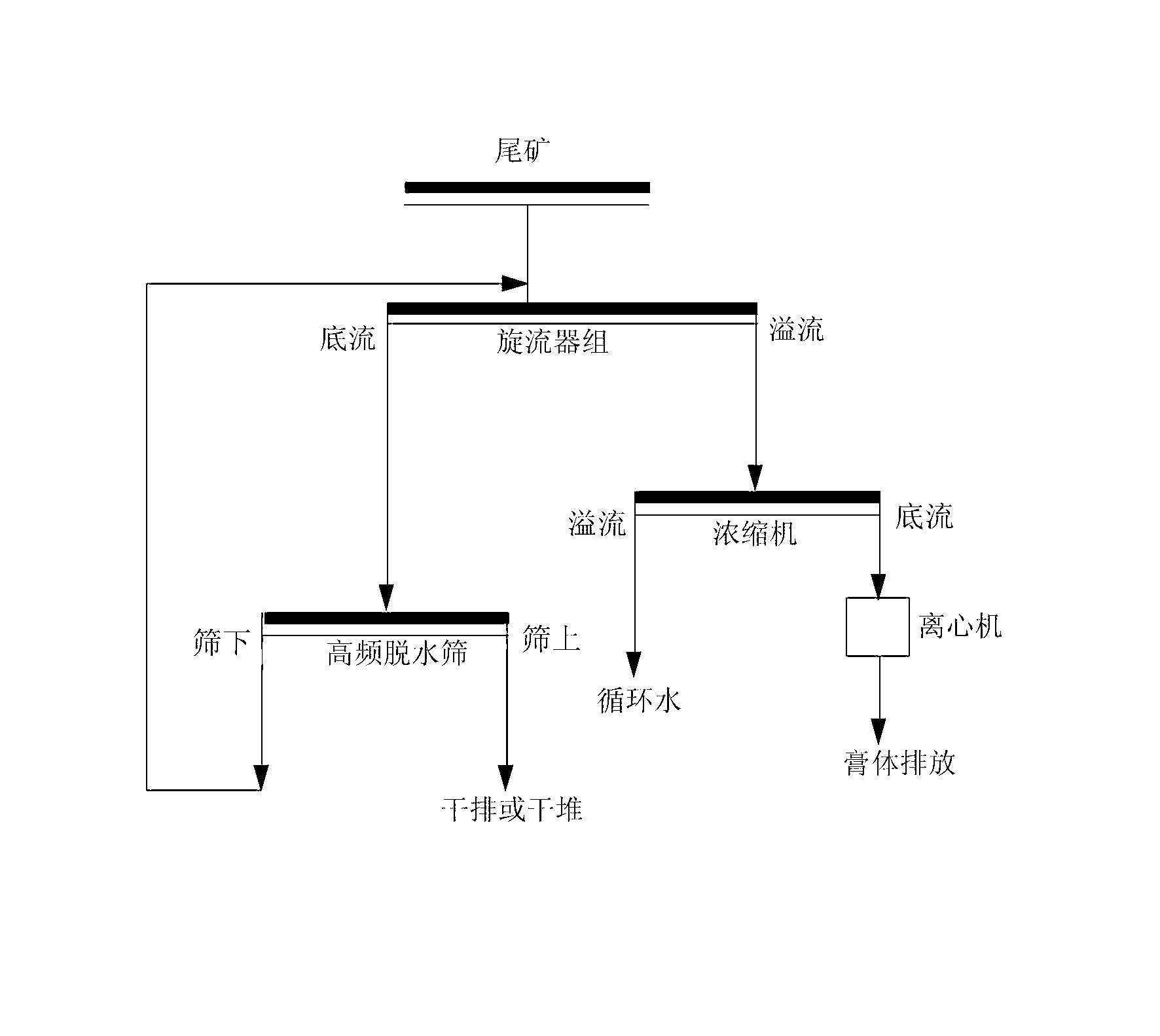

[0021] Below in conjunction with accompanying drawing, the present invention is described further.

[0022] Such as figure 1 As shown, the iron tailings paste conveying process of the present invention comprises the following steps: the tailings with a concentration of 15%-25% are classified by a cyclone to form underflow coarse-grained product concentration 55%-65% and overflow fine-grained The product concentration is 10%-15%, which is characterized in that the underflow coarse-grained product classified by the cyclone is fed into the high-frequency dewatering screen, and the product on the high-frequency dewatering screen is tailings dry sand with a concentration of 80%-85% , while the under-screen product of the high-frequency dehydration screen returns to the cyclone to form a closed loop, and the overflow fine-grained product classified by the cyclone is transported to the paste thickener to the ore box by the slurry pump, and then flows by itself Into the paste thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com