Method for taking and manufacturing guide tube real samples

A manufacturing method and catheter technology, applied in the field of actual sample preparation, can solve the problems of reducing catheter efficiency and manufacturing accuracy, and the bending size and precision are difficult to meet the numerical control bending conditions, so as to improve the manufacturing speed and accuracy, ensure efficiency and The effect of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

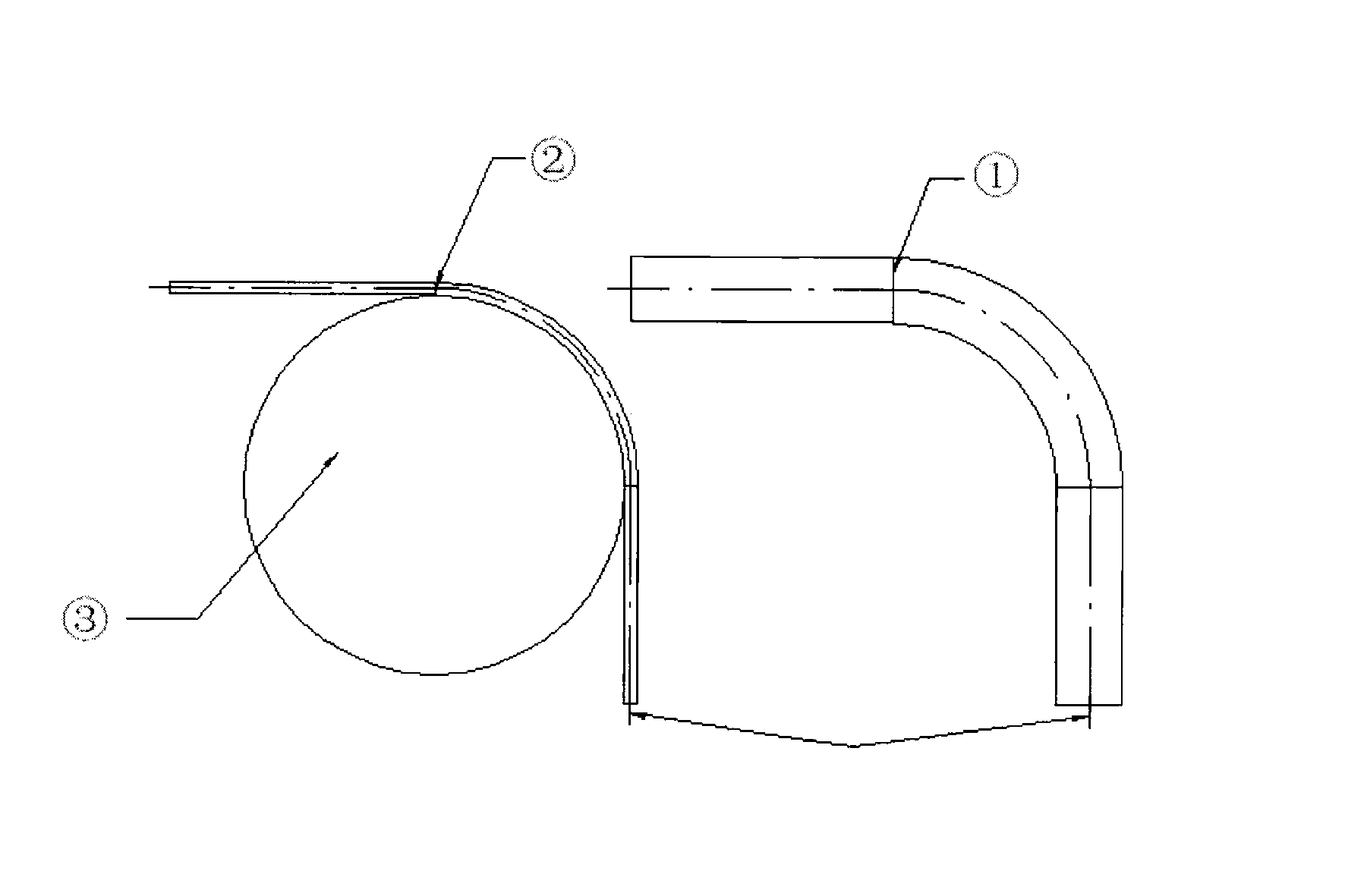

[0015] Because large-scale machinery requires many tubes, it is impossible to manufacture corresponding sample tube bending molds according to the shape of each tube, so the tube bending parameters should follow the set numerical control bending conditions. Generally, the numerical control bending conditions are set as follows: the center line of the actual tube is bent The radius R is an integral multiple of 0.5 times the actual outer diameter of the catheter D, and the minimum is 2D, for example, 2.5D, 3D, etc.

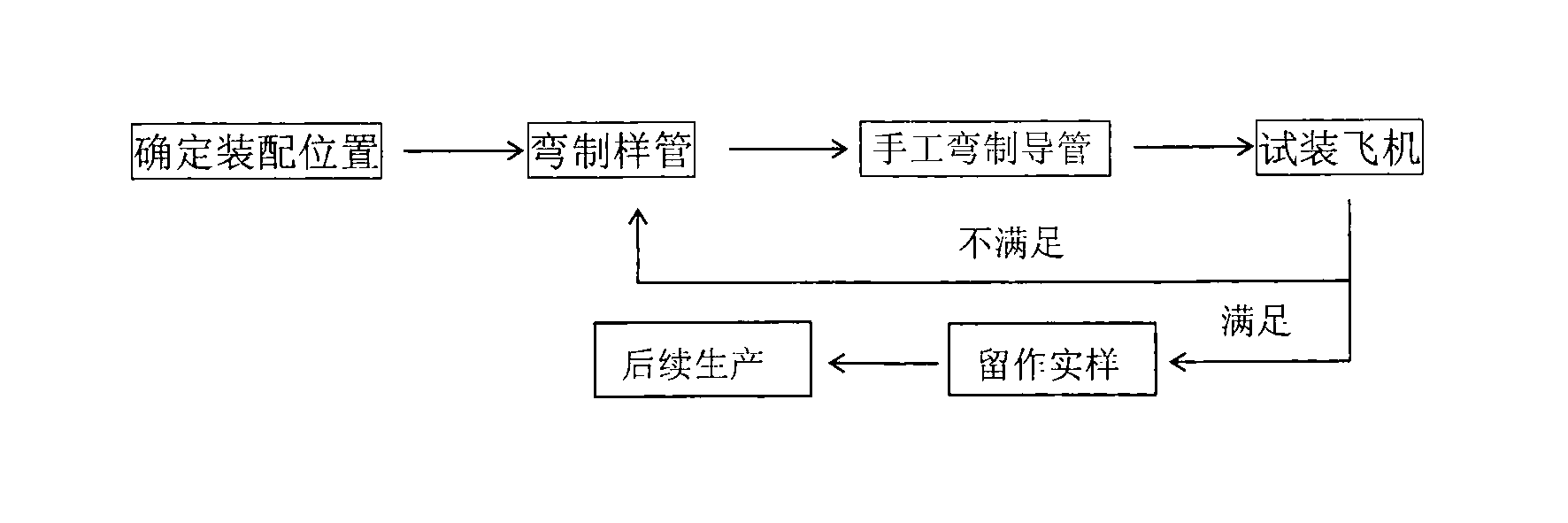

[0016] A kind of catheter real sample preparation method, such as Figure 4 As shown, the specific method is as follows:

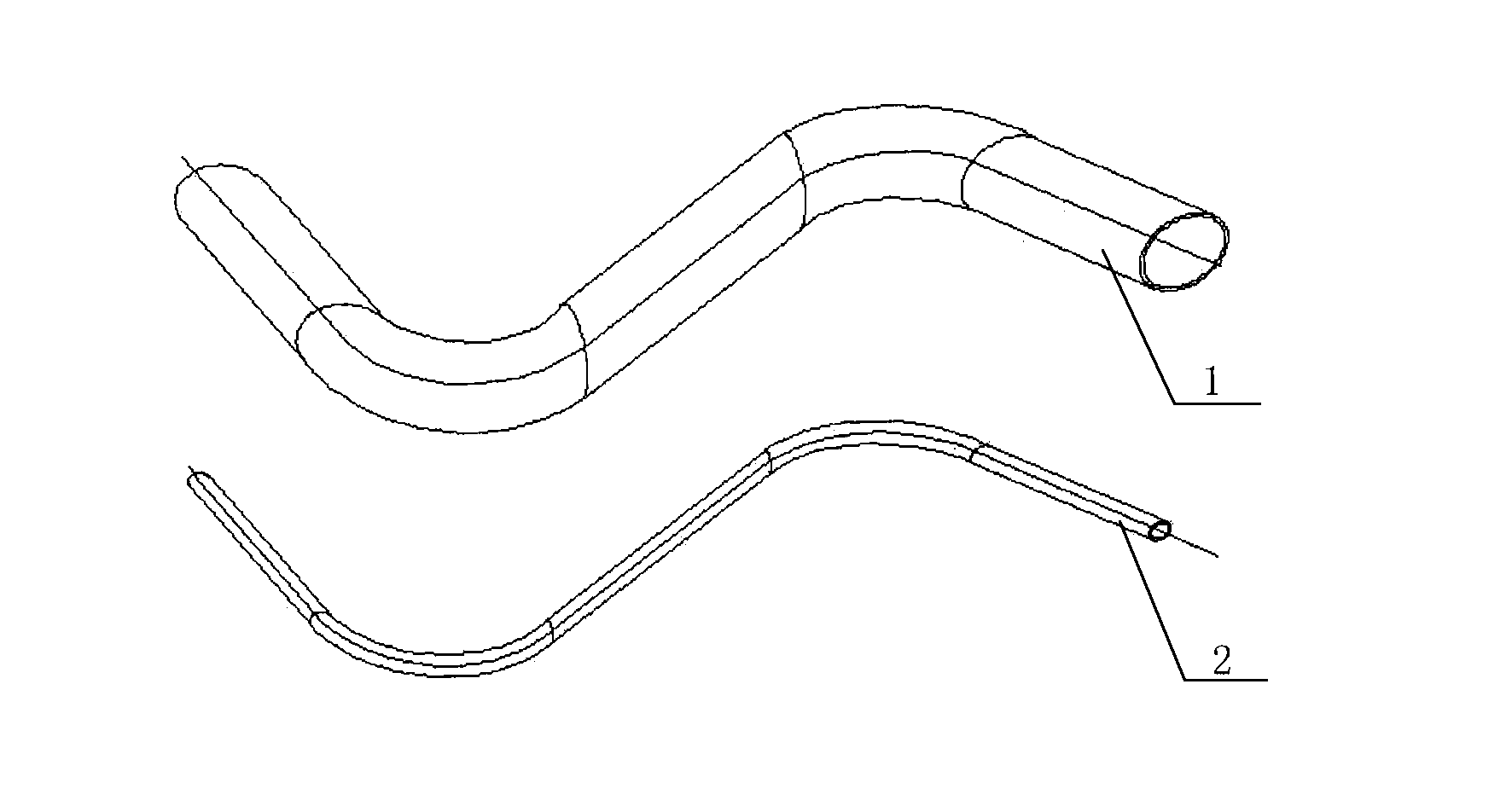

[0017] 1) According to the assembly space and the size of the actual catheter sample 1, according to the numerical control bending conditions, select the sample tube bending mold 3 of the corresponding size; take the actual catheter sample 1 with an outer diameter of φ30mm as an example, select the bending radius as 3D, and use a φ6mm sample tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com