One-time forming system of spring bars former, and forming method of spring bars

A technology of forming machine and elastic strip, applied in the field of elastic strip production, can solve the problems of easy drawing and thinning of the bar material, the temperature of the bar material dropping too much, and the forming operation being complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below according to the drawings and embodiments.

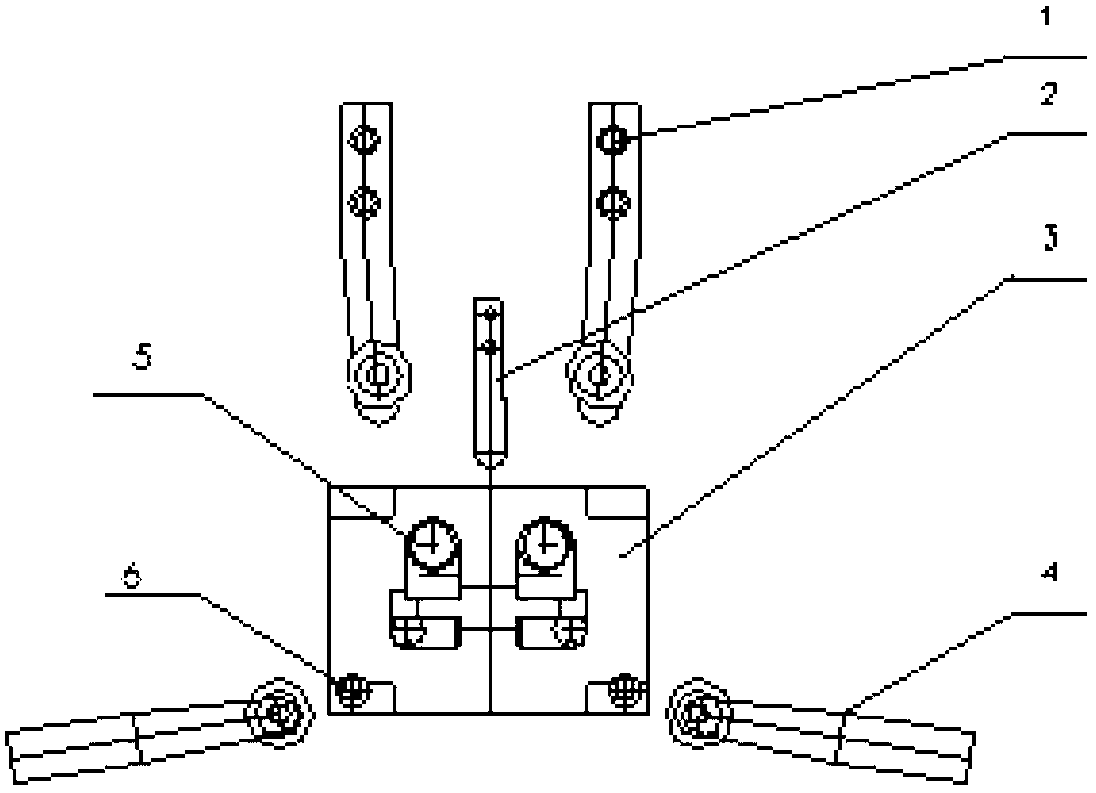

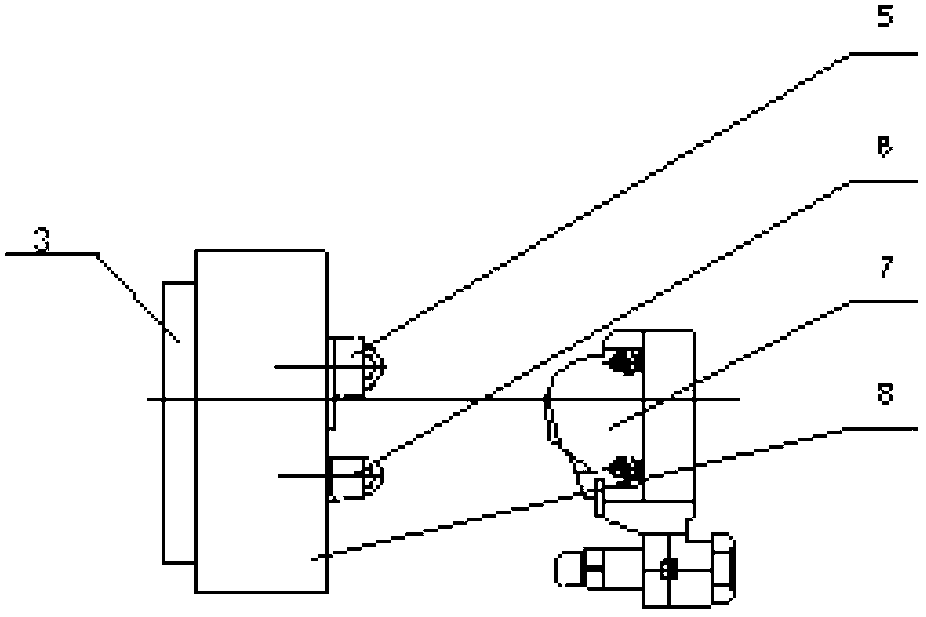

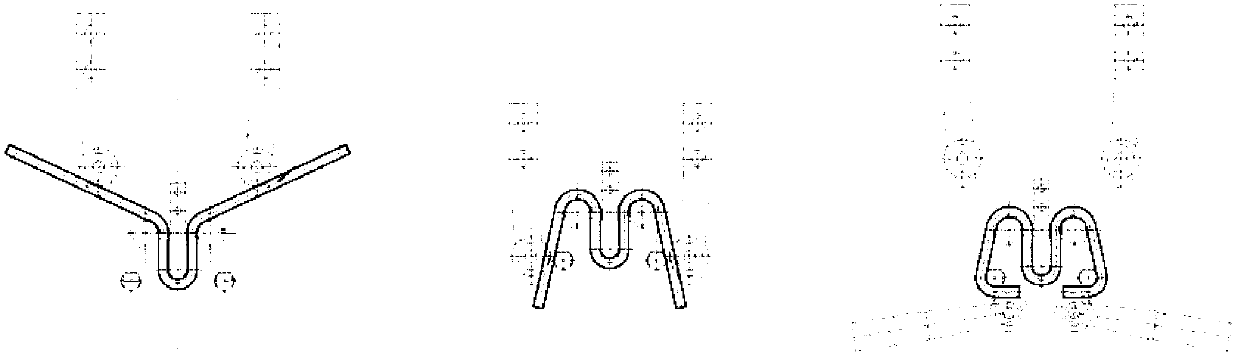

[0030] figure 1 It is the front view of the one-time molding system of the clip molding machine in this implementation case, figure 2 It is a side view of the one-time molding system of the clip molding machine in this implementation case, and it is also referred to figure 1 , figure 2 , the present invention, the one-time forming system of the elastic strip forming machine includes an upper mold 7, a lower mold 3, an upper positioning column 5, a lower positioning column 6, a middle push arm 2, two side push arms 1, and two limb push arms 4;

[0031] Wherein, the surface of the upper mold 7 is facing the surface of the lower mold 3;

[0032] Both the upper positioning column 5 and the lower positioning column 6 are provided with two, the above-mentioned two upper positioning columns 5 are symmetrically fixed above the surface of the lower mold 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com