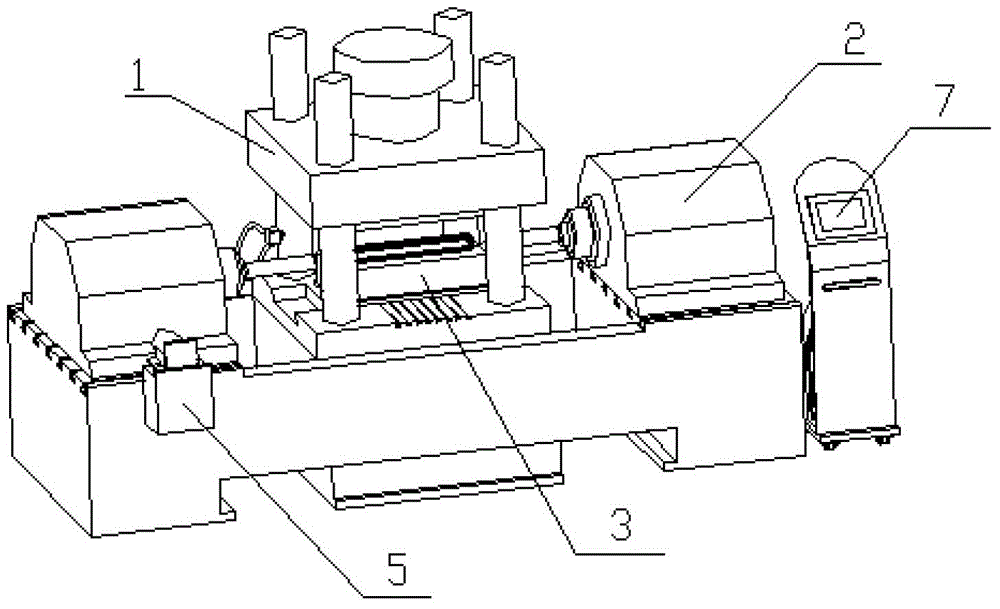

Inner high pressure forming quick die assembling method and equipment

An internal high-pressure forming and rapid technology, applied in the field of high-pressure forming of pipes, can solve the problems of error affecting product forming quality, difficulty in precise fine-tuning, inconvenient operation, etc., and achieve compact mold space, improve uniformity, and fast clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

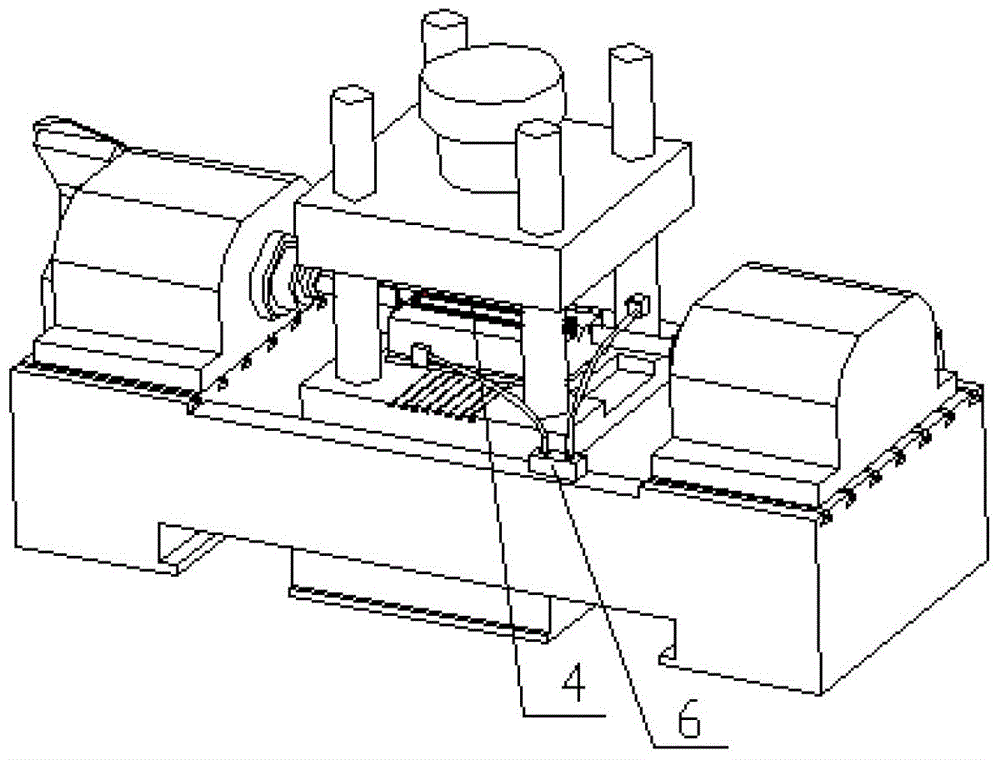

Embodiment Construction

[0023] Operation steps of the present invention are as follows:

[0024] Step 1: Before making internal high pressure products, first of all, adjust the coaxiality of the mold feeding cavity axis and the feeding rod axis, and position the blank tube; use the first camera to collect data information, and process the feedback through the computer. The image of the matching position of the coaxiality between the axis of the mold feeding cavity and the axis of the feeding rod is displayed on the display screen, and the position of the mold or the horizontal cylinder can be adjusted by comparing the two; the first camera and the second camera pass through the disk mounting seat The magnetic force is fixed on the clamping press, and the mounting seat has a permanent magnet;

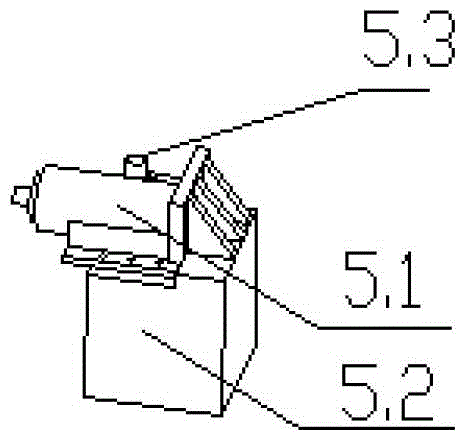

[0025] Step 2: Based on the deviation of the positional relationship displayed in step 1, absorb the fixed mechanical fine-tuning mechanism to the position that needs to be adjusted; through the strong magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com