Composite efficient double-end-face chamfering machine of internal and external teeth of polar coordinates

A technology of internal and external teeth and polar coordinates, which is applied in the direction of gear teeth, mechanical equipment, and components with teeth, etc., can solve the problems of uneven chamfering and low efficiency of manual chamfering, so as to reduce quenching cracks on the end face and avoid chamfering Uneven, easy-to-handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

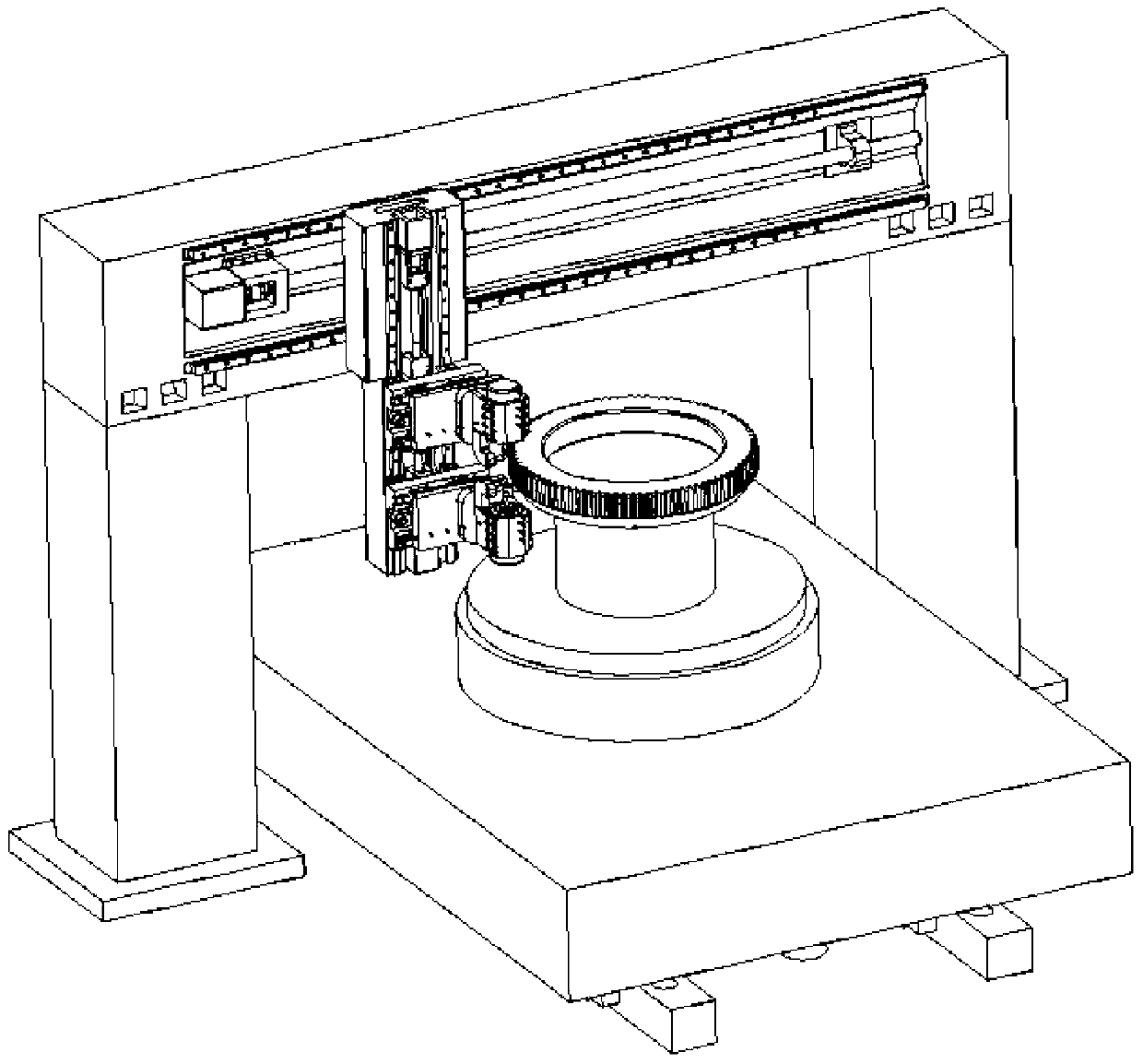

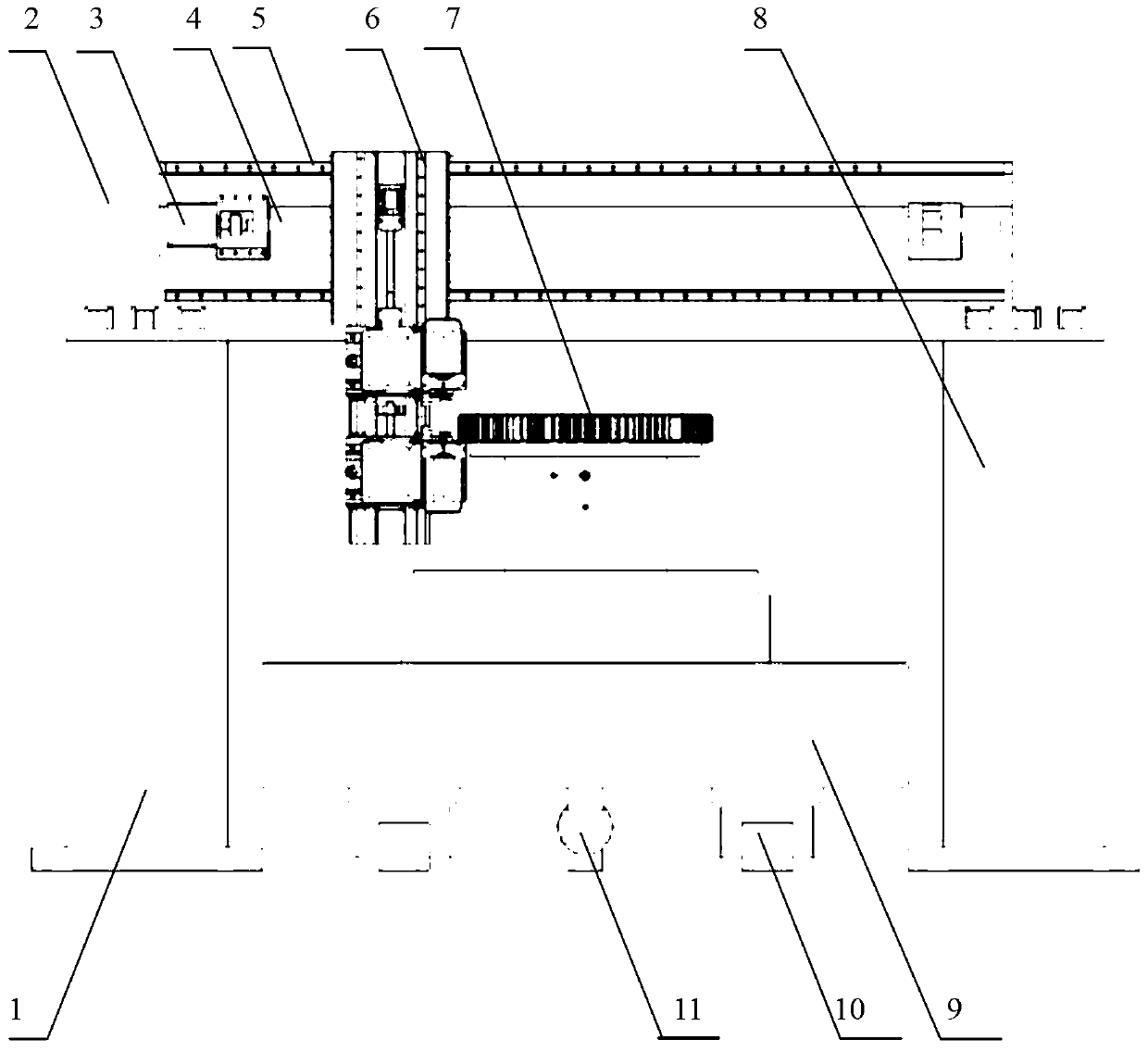

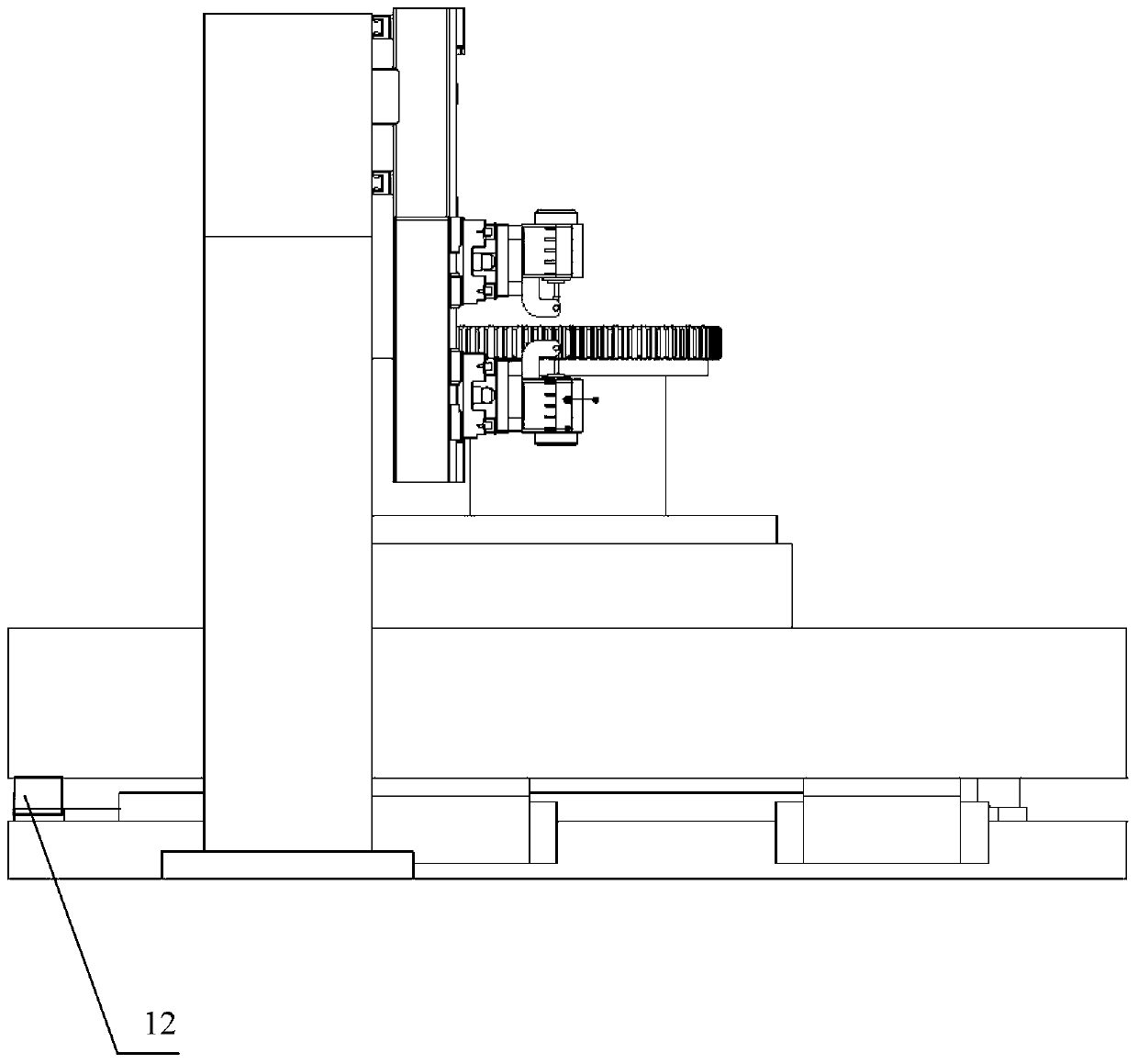

[0031] The chamfering machine of the present invention is mainly composed of a gantry frame, a Y-axis servo motor 3, a Y-axis ball screw 4, a Y-axis rail 5, a radial positioning slide table 6, a workpiece 7, a horizontal rectangular workbench 9, and an X-axis supporting line rail 10 and X-axis driving cylinder 11, Y-axis servo motor 3 and Y-axis rail 5 are set on the gantry frame, Y-axis servo motor 3 is connected to Y-axis ball screw 4, and Y-axis ball screw 4 is connected to radial positioning slide table 6. The workpiece 7 is set on the horizontal rectangular workbench 9, and the bottom of the horizontal rectangular workbench 9 is provided with an X-axis supporting line rail 10 and an X-axis driving cylinder 11.

[0032] The gantry frame includes a left column 1, a right column 8 and a crossbeam 2. The bottom ends of the left column 1 and the right column 8 are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com