Precast pile, beam and slab renovation technology for diseases of existing line tunnel base

A technology of prefabricated piles and existing lines, which is used in infrastructure engineering, construction and other directions to achieve the effects of reducing construction time, easy post-maintenance and high production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

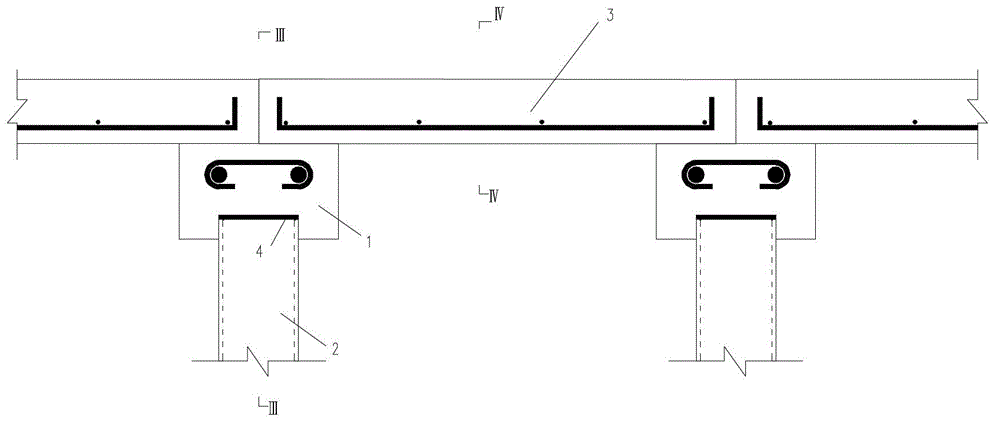

[0028] (1) According to the requirements of tunnel foundation disease treatment, prefabricate and produce cylindrical piles, beams and slabs, beams such as Figure 4 As shown, the board as Figure 5 shown.

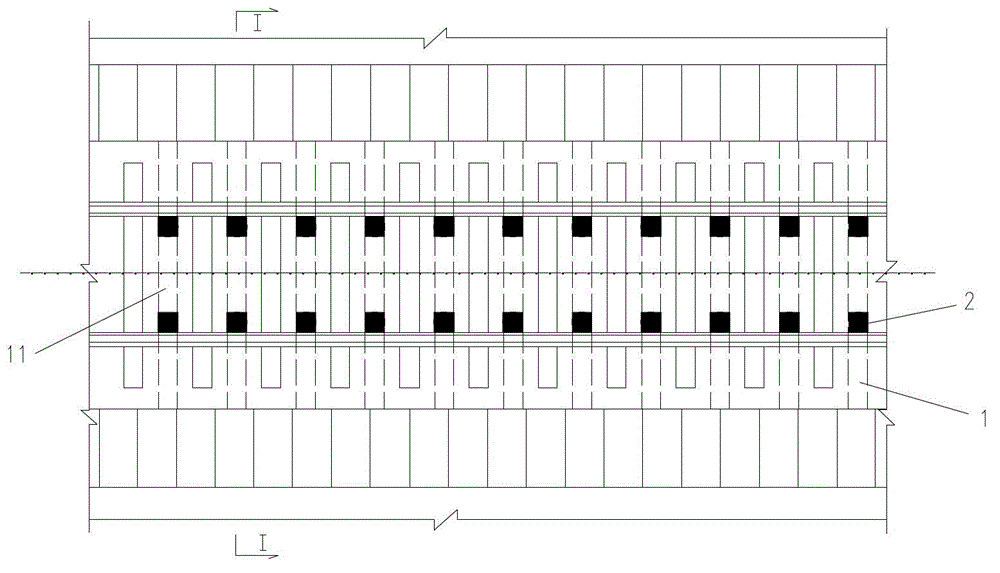

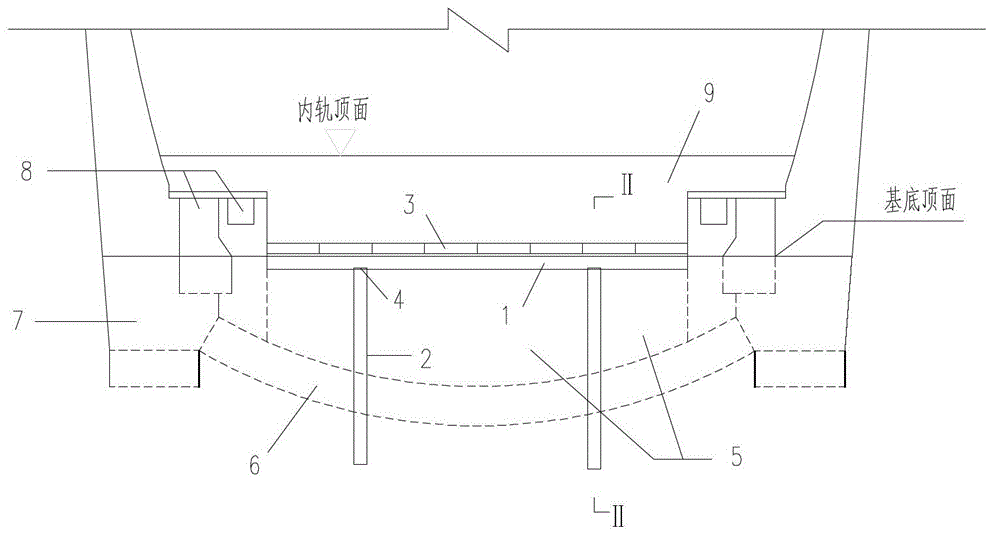

[0029] (2) Constrained beam overhead lines are used, such as figure 1 As shown, first, according to the placement position requirements of the beam structure 2, the base structure is cut 11, and the groove 11 is perpendicular to the track. According to the placement requirements of the pile structure 2, drilling operations are carried out in the beam cutout.

[0030] (3) if figure 2 As shown, clean the pile hole and embed the prefabricated pile 2, and carry out the grouting operation to compact the gap around the pile;

[0031] (4) After the strength of the filling grout between the prefabricated pile and the hole wall reaches 10Mpa, place the metal backing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com