A scraper type coal mining machine

A shearer and scraper type technology, applied in the mining industry, can solve problems such as unbalanced coal falling, easy rope jamming and broken rope, complex structure, etc., to improve safety and work efficiency, reduce minimum thickness, and increase versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

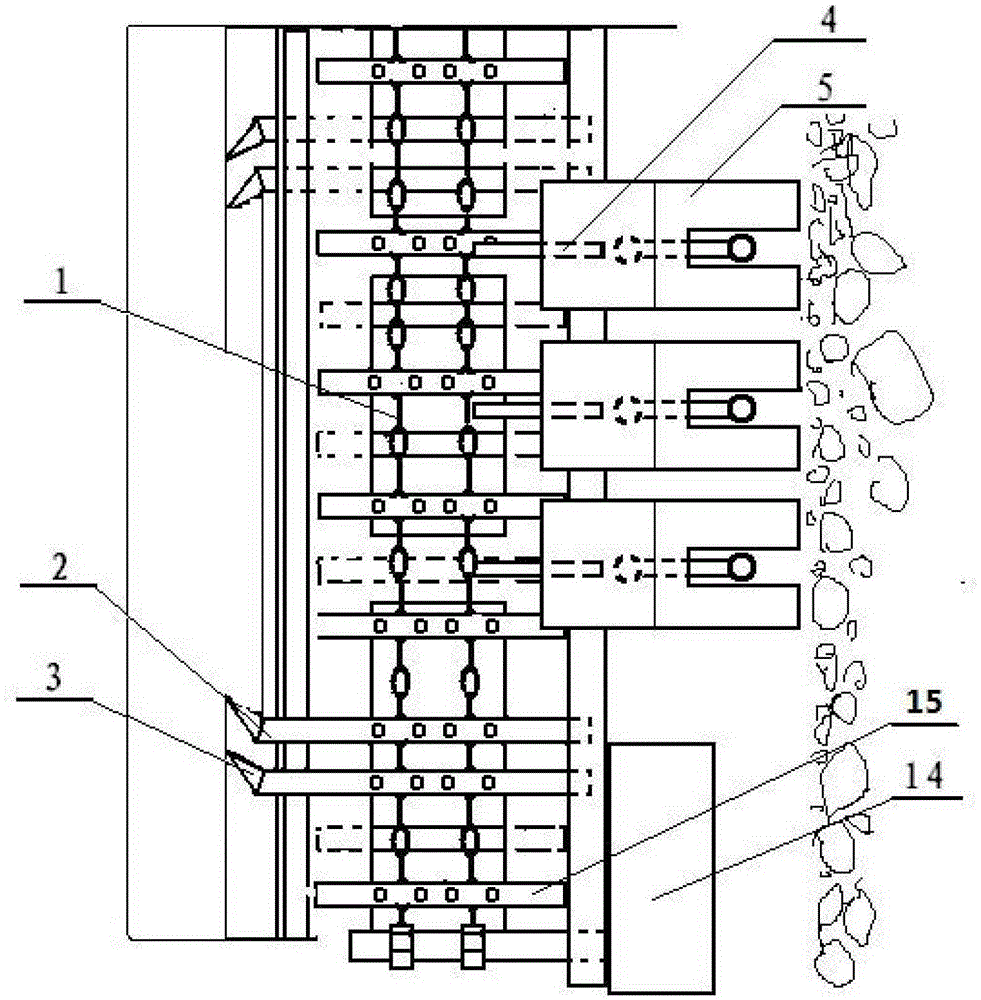

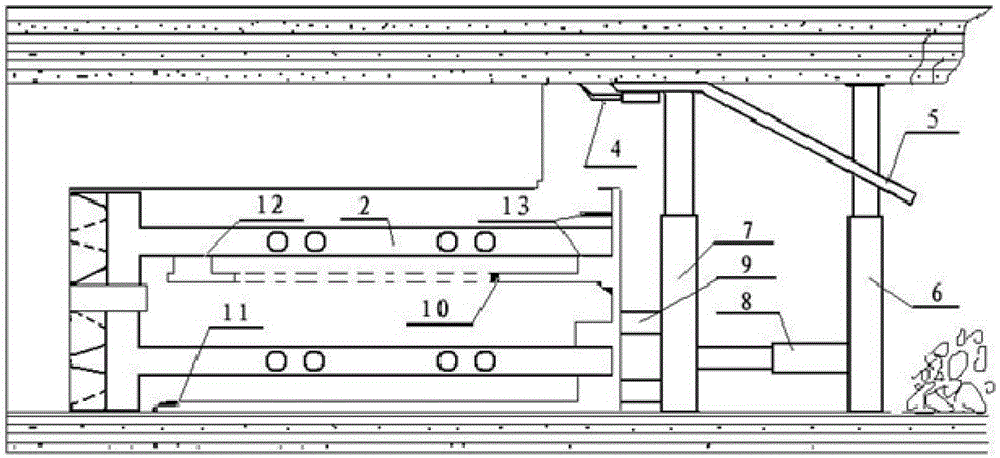

[0019] Embodiment 1: as figure 1 and figure 2 shown

[0020] A scraper type coal mining machine comprises: a scraper conveyor, on which a transport trough is arranged, and one side of the transport trough along its length direction is open, and its top surface 10 is in the shape of a mesh.

[0021] Along the length direction of the transport trough, an endless transport chain 1 is arranged in the transport trough, and coal scrapers 15 are evenly spaced on the endless transport chain 1 , and the endless transport chain 1 is in the form of upper and lower sides in the transport trough. Layer transport chain distribution.

[0022] A group of coal scraping plates 15 equipped with coal scraping teeth 3 are respectively arranged on the upper and lower layers of the transport chain, which are coal scraping tooth plates 2, and a set of said coal scraping tooth plates 2 includes two said coal scraping tooth plates 2, two The two coal scraping tooth plates 2 are adjacently arranged ...

Embodiment 2

[0034] A scraper type coal mining machine comprises: a scraper conveyor, on which a transport trough is arranged, and one side of the transport trough along its length direction is open, and its top surface 10 is in the shape of a mesh.

[0035] Along the length direction of the transport trough, an endless transport chain 1 is arranged in the transport trough, and coal scrapers 15 are evenly spaced on the endless transport chain 1 , and the endless transport chain 1 is in the form of upper and lower sides in the transport trough. Layer transport chain distribution.

[0036] A group of coal scraping plates 15 equipped with coal scraping teeth 3 are respectively arranged on the upper and lower layers of the transport chain, which are coal scraping tooth plates 2, and a set of said coal scraping tooth plates 2 includes two said coal scraping tooth plates 2, two The two coal scraping tooth plates 2 are adjacently arranged side by side.

[0037] Driven by the motor 14, during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com