Anti-icing wind power blade and preparation method of anti-icing wind power blade

A wind power blade and anti-icing technology, applied in wind power generation, wind turbine components, wind turbine control, etc., to reduce unplanned downtime, not easy to damage, and avoid too high temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

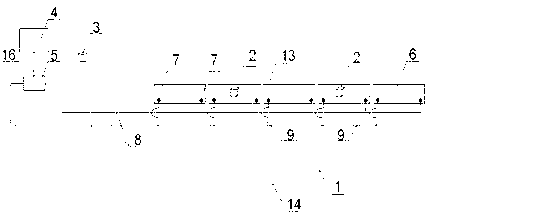

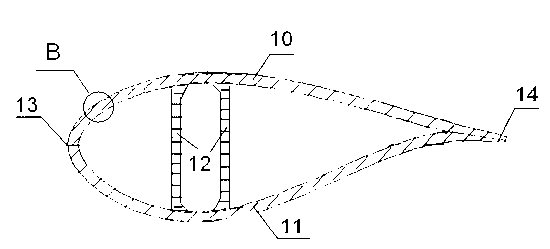

[0026] The anti-icing wind power blade of the present invention includes a monitoring system, a blade body connected to a wind power generator, and a power supply. Shear webs supporting the inner walls of the suction and pressure side shells;

[0027] Among them, a polymer electric heating film is sandwiched between the outer surfaces of the suction surface shell and the pressure surface shell or the reinforcing material layer constituting the shell; the two ends of the polymer electric heating film are provided with electrodes, and the main lead and the main lead are connected through branch wires. Peripheral power connection;

[0028] The monitoring system is divided into a monitoring unit and a control unit; the monitoring unit is an ambient temperature and humidity sensor and at least one blade surface temperature sensor; wherein, the ambient temperature and humidity sensor is installed above the wind turbine cabin or on its hub; the blade surface temperature The sensor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com