Ultrasonic welding structure of plastic planetary gearbox

A planetary gearbox, ultrasonic welding technology, applied in the direction of transmission boxes, components with teeth, etc., can solve problems such as easy loosening, gear stuck, etc., to ensure stability, prevent the gearbox shell from loosening, improve reliability and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

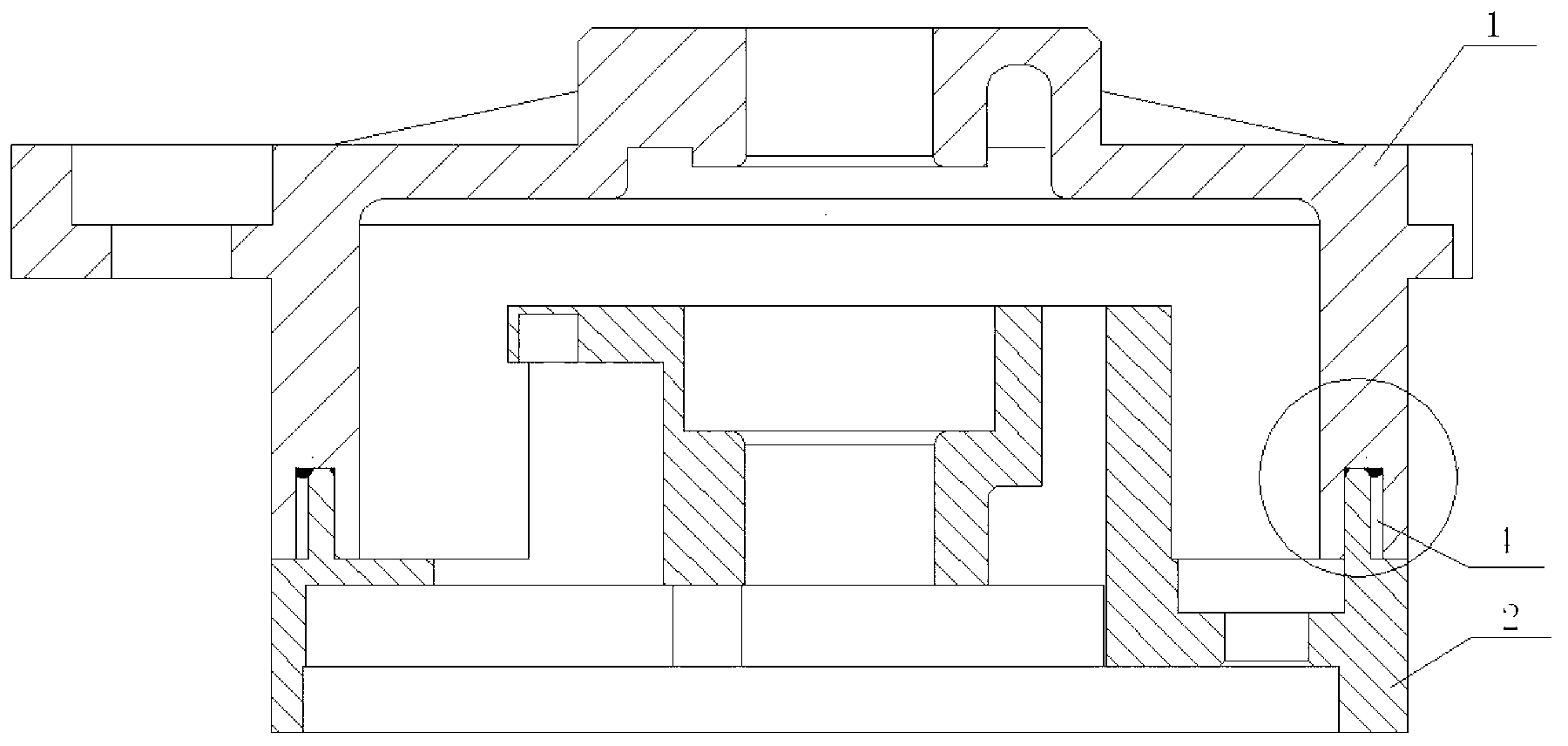

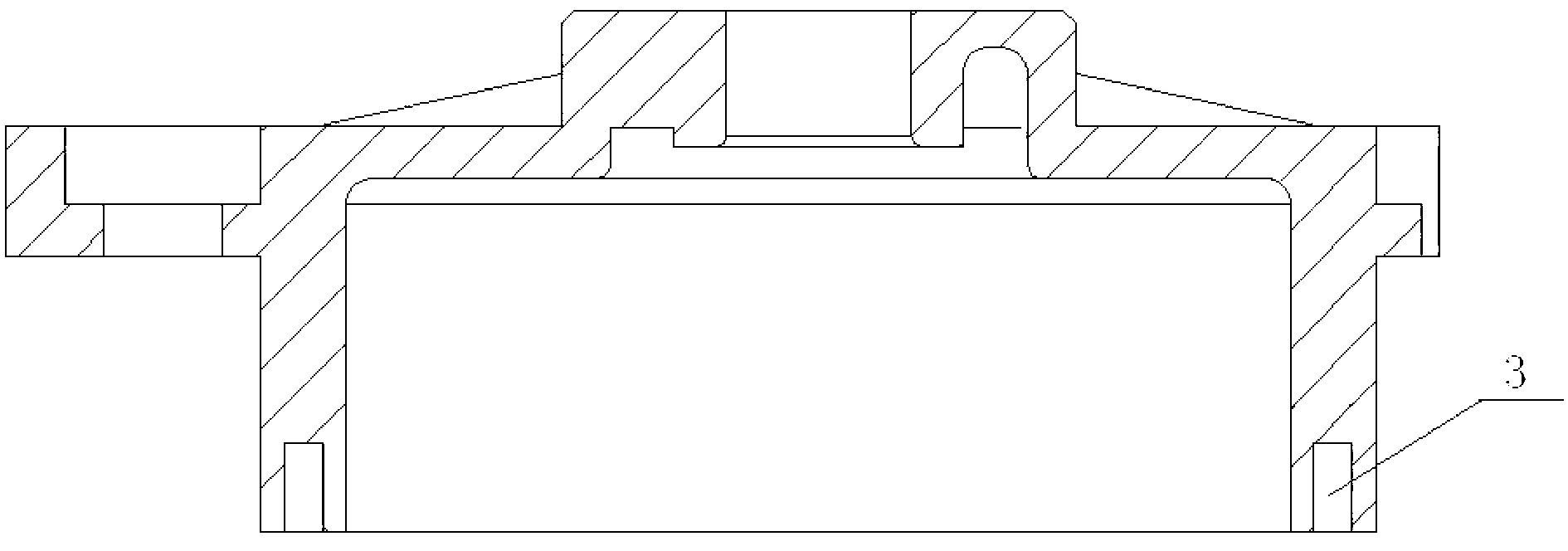

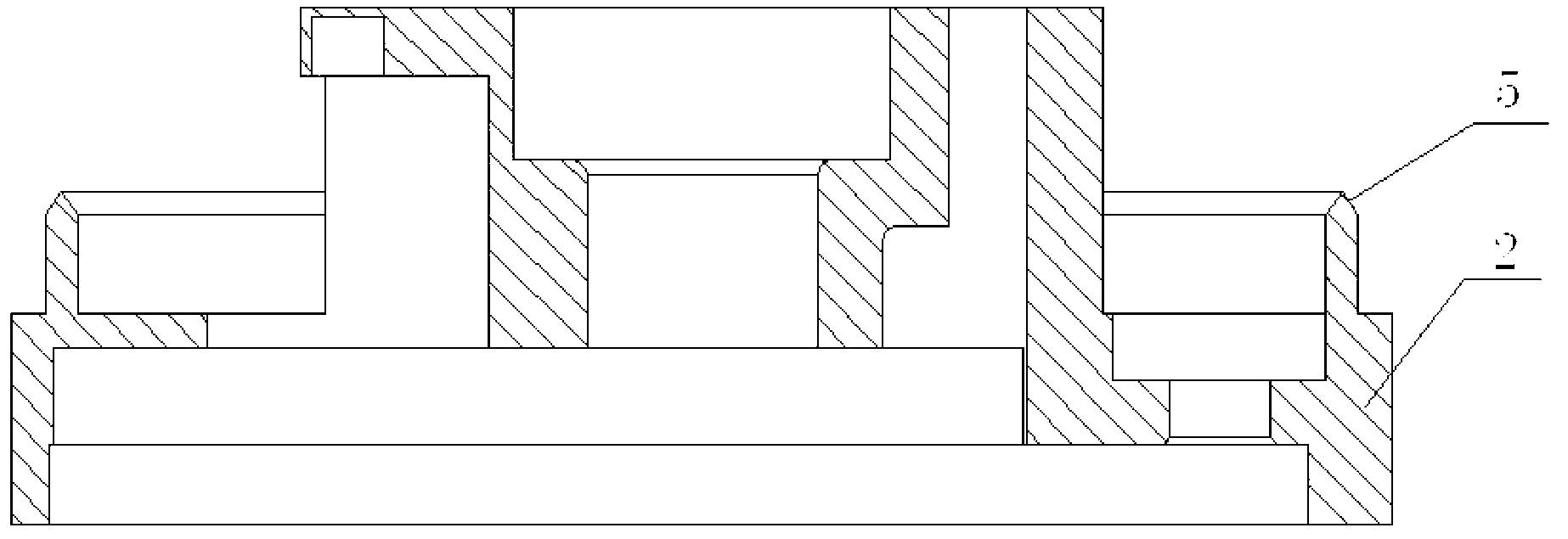

[0017] A plastic planetary gearbox ultrasonic welding structure, such as figure 1 As shown, it includes a gear case upper case 1 and a gear case middle case 2 that are matched. An annular welding groove 3 is arranged on the annular side wall of the upper shell of the gear box, and the cross section of the welding groove 3 is rectangular, such as figure 2 shown. The inner end face of the gear box middle shell matches the inner end face of the welding groove 3, and a packing cavity 4 is arranged between the outer end face of the welding groove 3 and the outer end face of the gear box middle shell. The middle shell of the gear box is in contact with the rectangular welding groove 3 and is provided with a welding angle 5 at the top corner of one side close to the stuffing cavity, and the angle of the welding angle is 45°, as shown in ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com