Accurate laser-level detection system

A detection system and level detection technology, which is applied in height/level measurement, measuring device, line-of-sight measurement, etc., can solve the problems of not being able to accurately know the digging depth of the excavator, the offset of the forearm and bucket, etc., to avoid vibration, The effect of guaranteeing accuracy and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

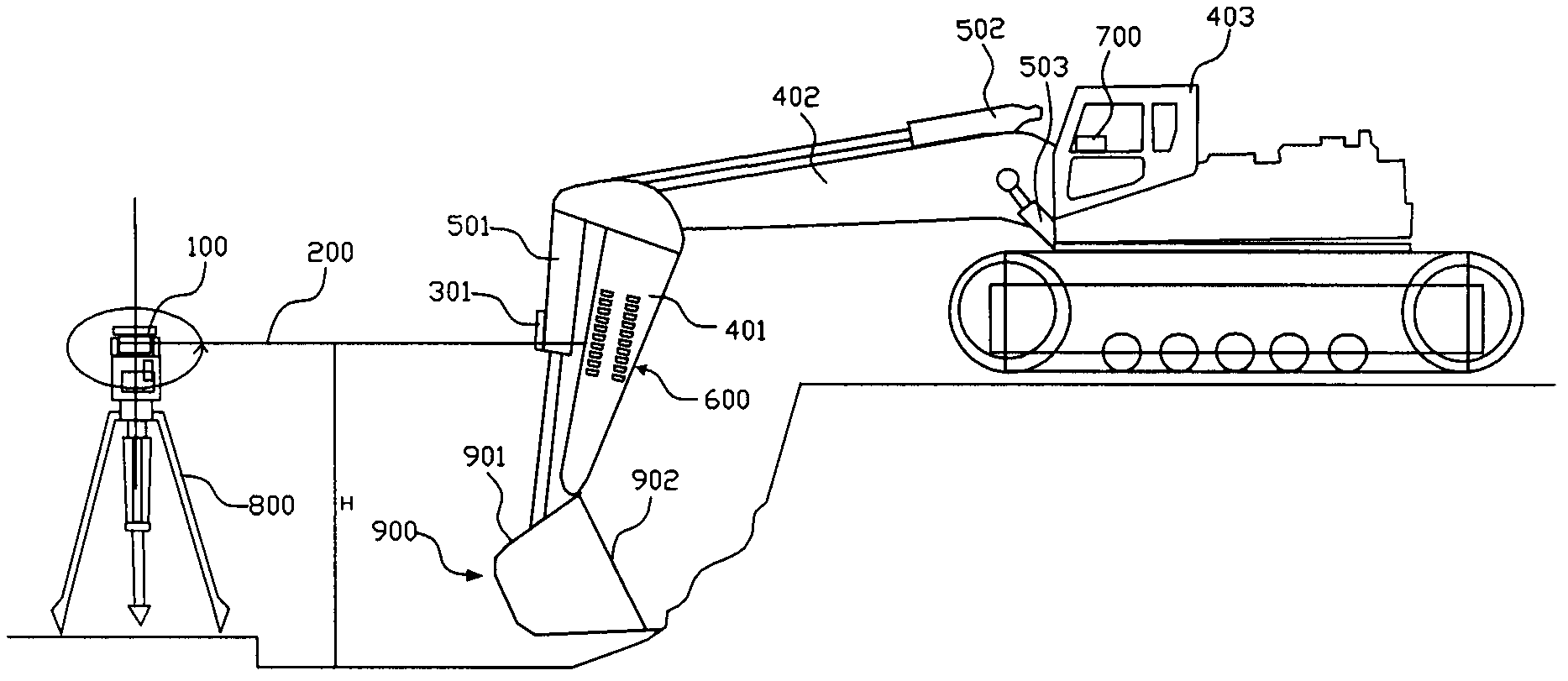

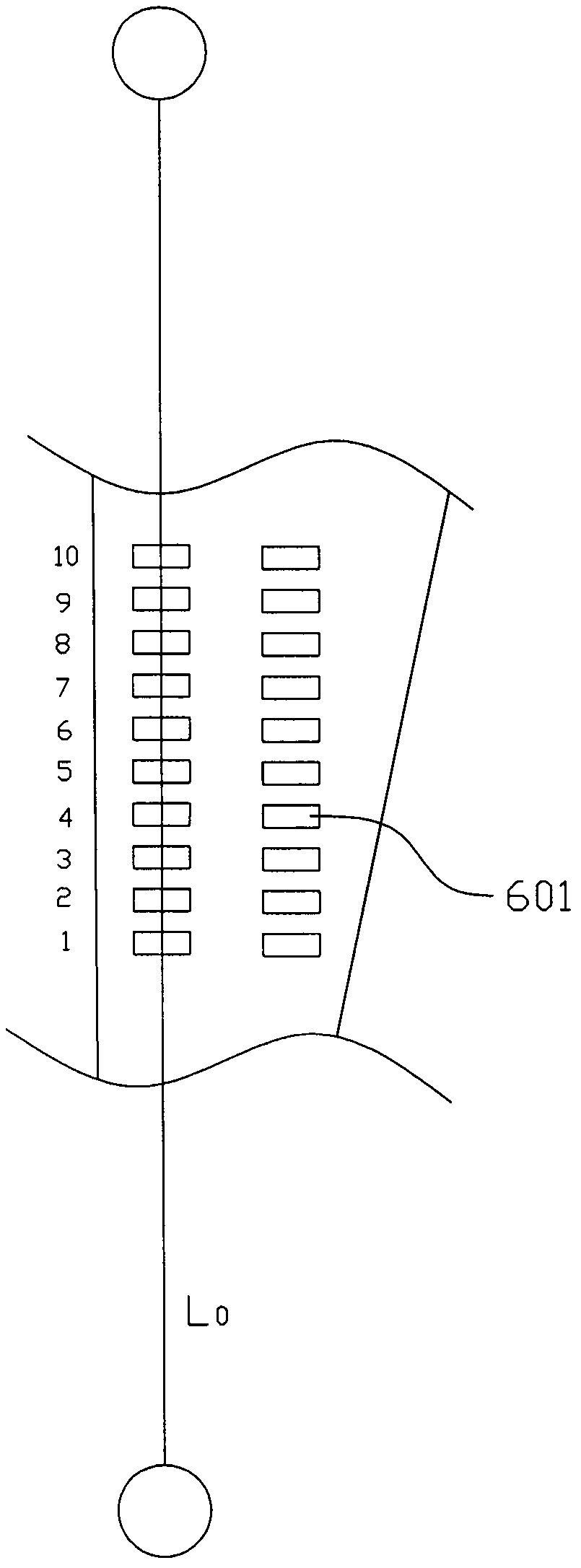

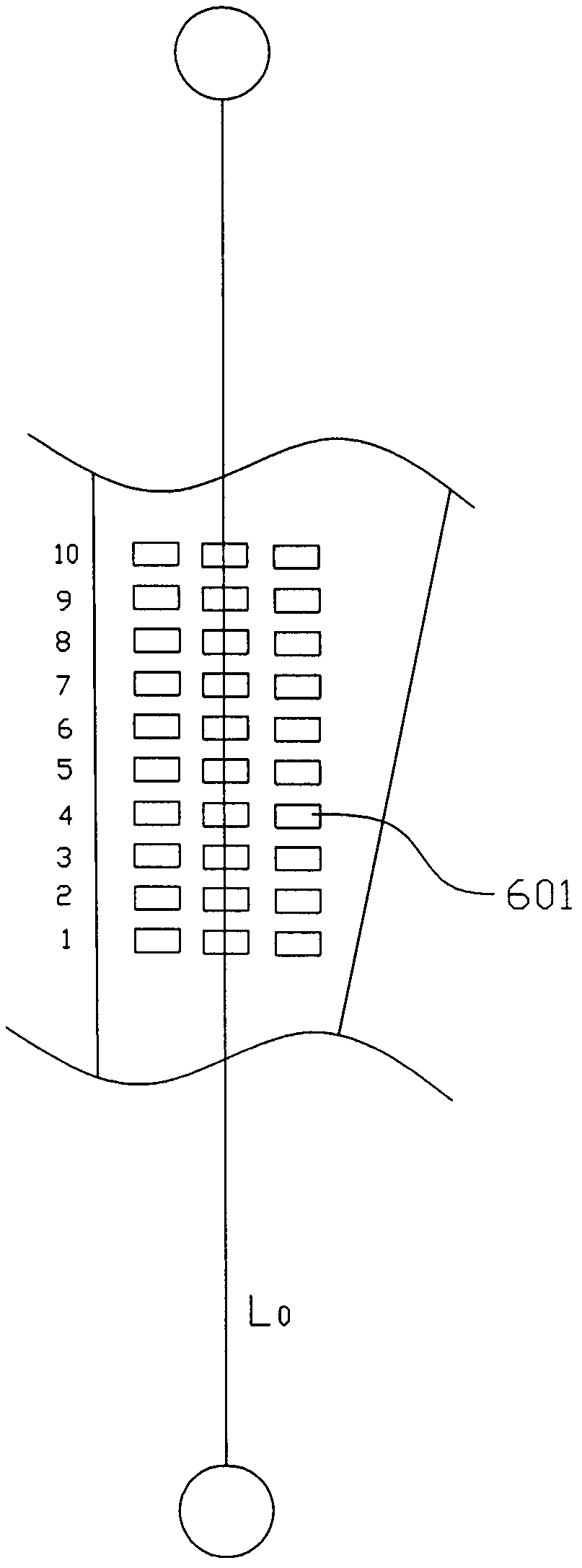

[0036] figure 1 Schematically shows a laser level accurate detection system according to an embodiment of the present invention, see figure 1 , the laser level precision detection system includes a rotating laser device 100 , a level detection device 600 , an operating device 700 and a first range finder 301 . Among them, the rotating laser device 100 is fixed on the flat ground through a tripod 800; the level detecting device 600 is arranged on the forearm 401 of the excavator, and the horizontal detecting device 600 combines the laser beam emitted horizontally by the rotating laser device 100 to detect The position signal of the photosensitive element of the offset angle between the forearm and the vertical plane; the first rangefinder 301 is respectively arranged on the hydraulic cylinder of the forearm 401 of the excavator, and is used to measure the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com