Measurement system for thin-film material tension-compression fatigue dynamic loading

A technology of dynamic loading and thin film materials, which is applied in the direction of measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure, which can solve the problems of low loading frequency, small loading displacement range, and low loading displacement accuracy. Achieve the effects of smooth movement, reasonable structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

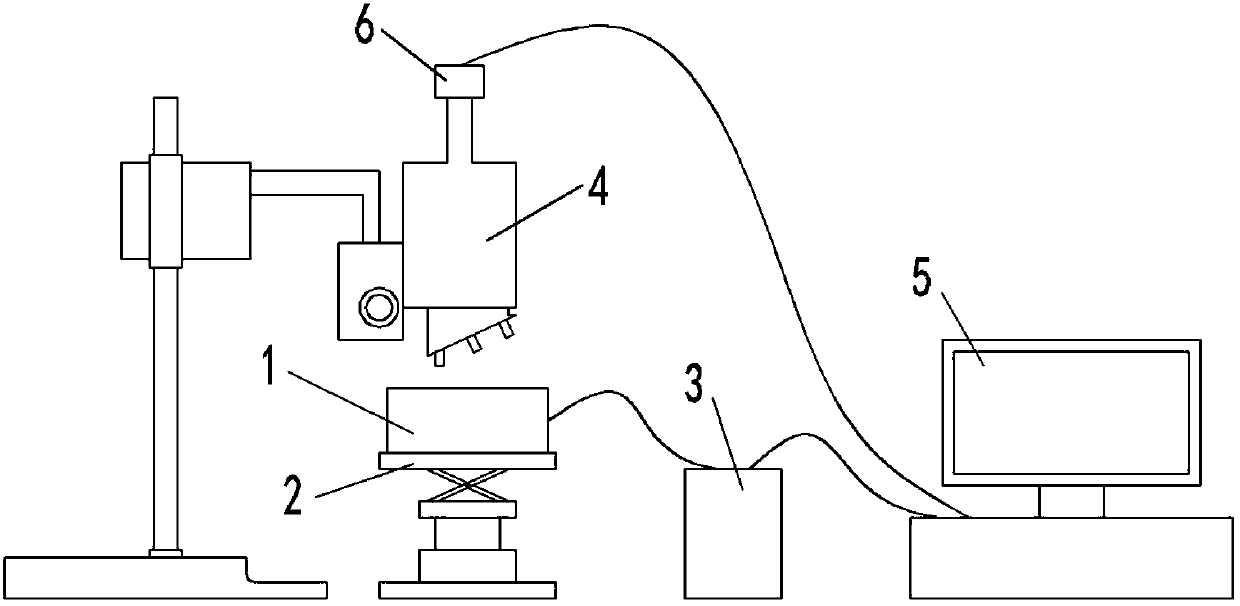

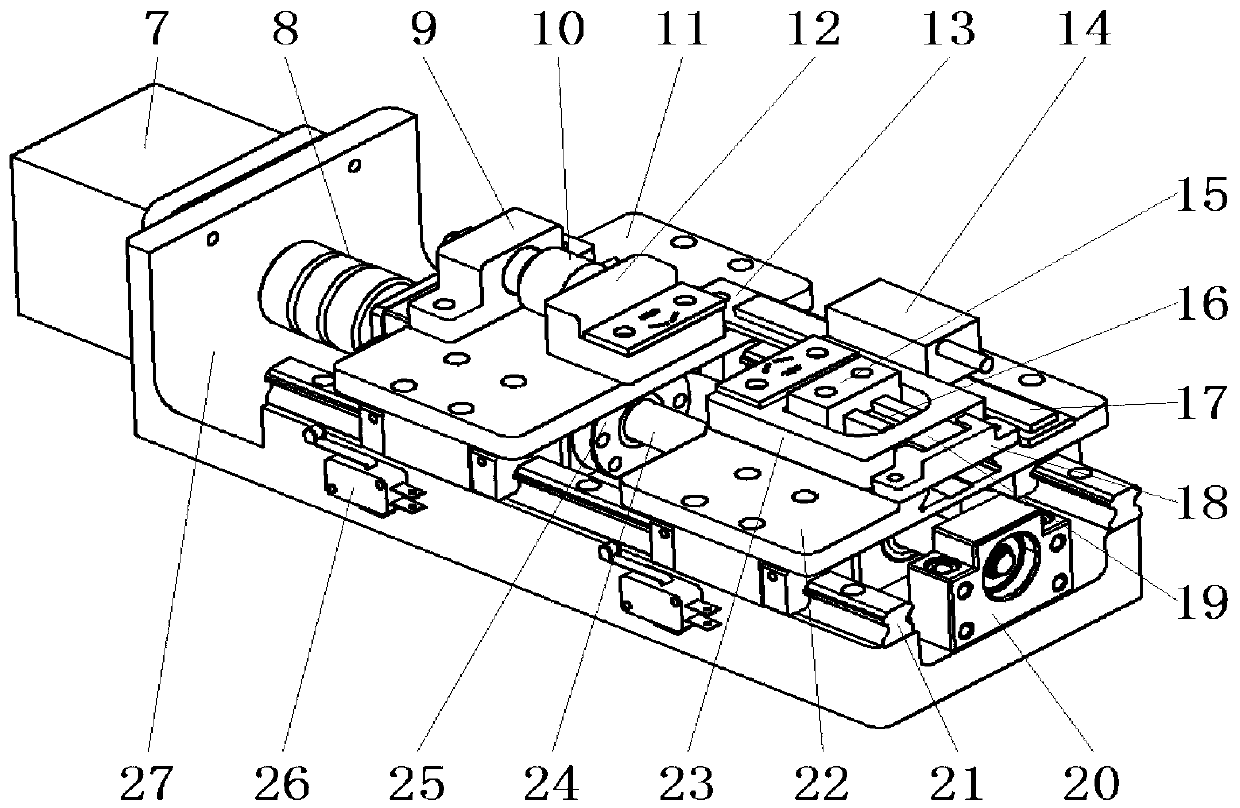

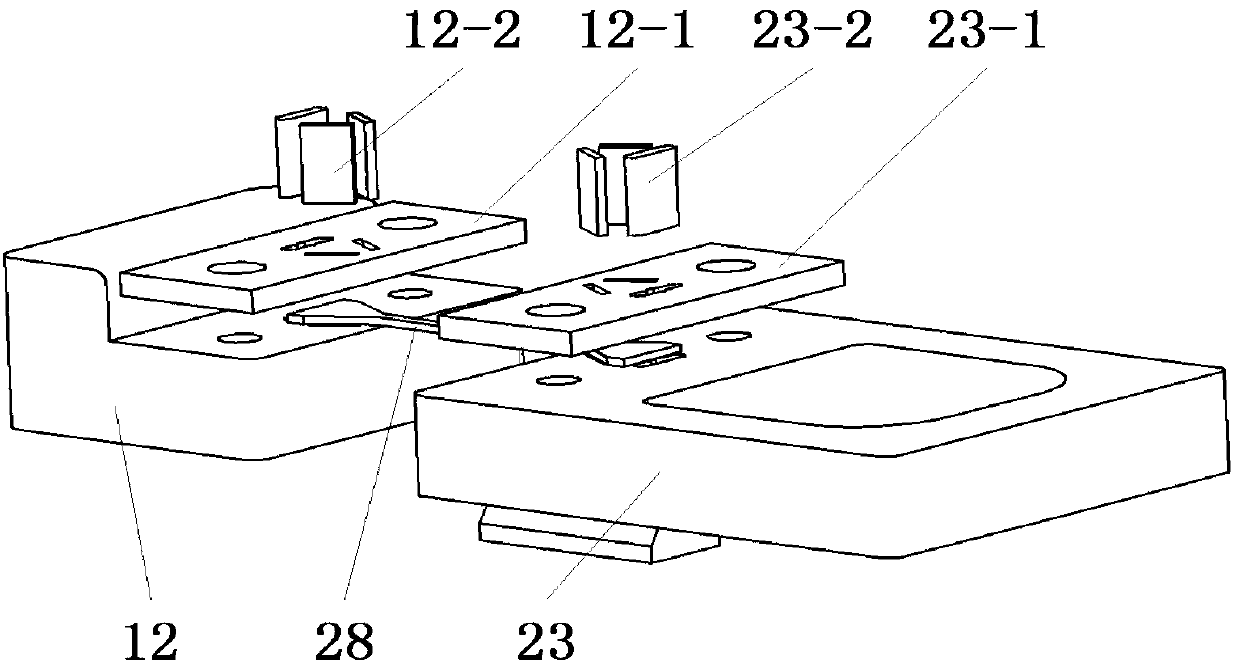

[0015] As shown in the figure, the tension-compression fatigue dynamic loading measurement system for thin film material of the present invention includes a dynamic loading device 1, the dynamic loading device is placed on the three-dimensional precision translation platform 2 under the optical microscope 4, and the CCD camera 6 is installed on The upper end of the eyepiece of the optical microscope, the dynamic loading device includes a stepper motor 7 installed on the base 27, the motor shaft of the stepper motor is connected with the two-way ball screw 24 through a shaft coupling 8, and the two-way The two ends of ball screw are supported and arranged in support seat 20, and described support seat is fixed on the base, is connected with left and right lead screw nut 25 on described two-way ball screw thread, in described left, right Left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com