Fatigue performance testing device and method for bolt bearing large load at low temperature

A technology of fatigue performance testing and testing equipment, which is applied in the direction of measuring equipment, applying stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as fatigue gaps, poor fatigue performance, and easy low-temperature cold and brittle bolt materials, etc. Achieve the effect of high feasibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

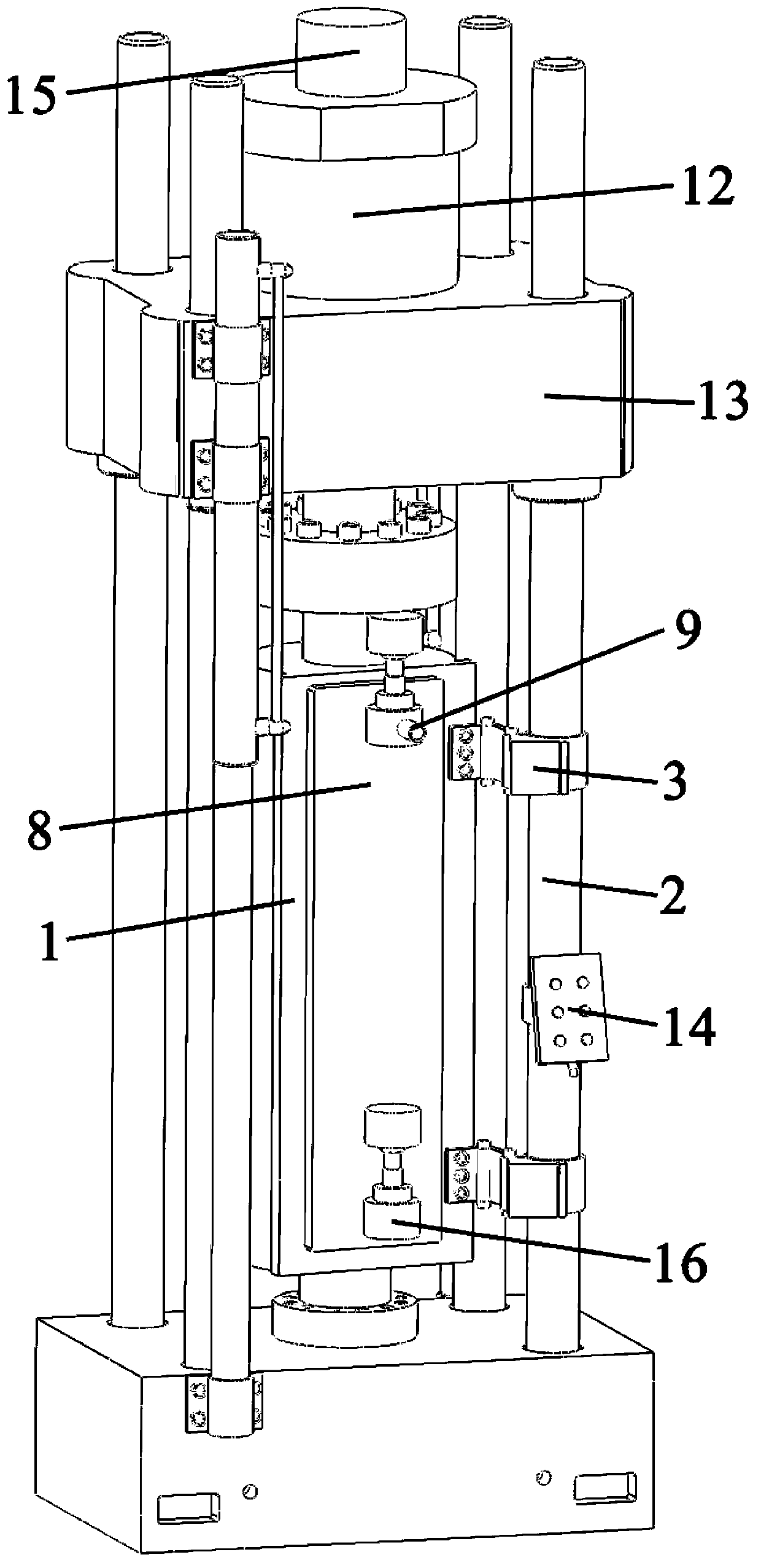

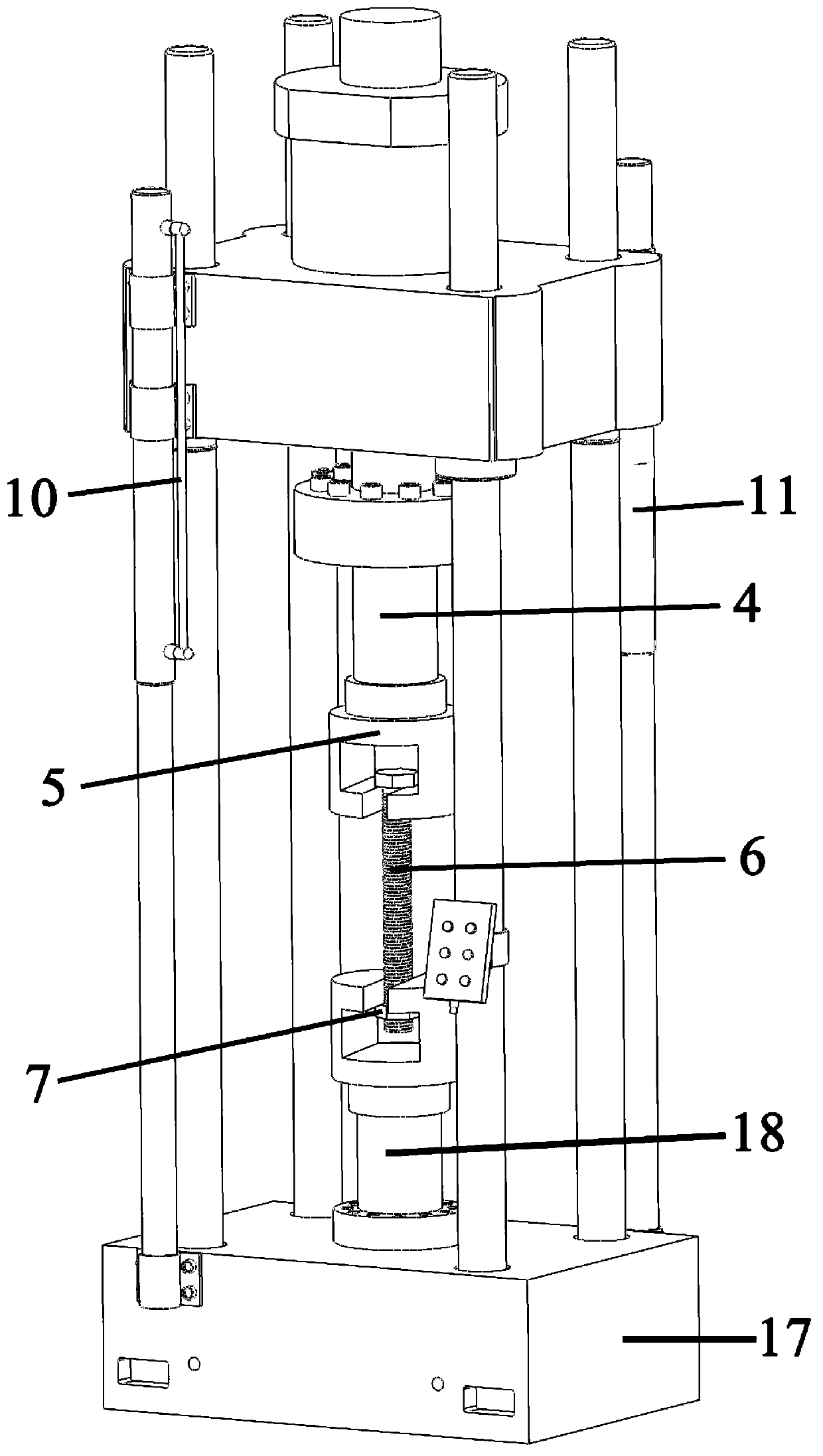

[0019] refer to figure 1 , figure 2 As shown, a fatigue performance test device for bolts under heavy loads in a low-temperature environment includes a low-temperature box 1 (in order to ensure the heat insulation performance of the low-temperature box, the box adopts a cylindrical configuration), a guide column 2, a rotating shaft device 3, Upper loading rod 4, test fixture 5, cryogenic chamber door 8, liquid nitrogen input port 9, limit locking device 10, beam lifting device 11, electro-hydraulic servo system 12, beam 13, control panel 14, linear variable differential Transformer (LVDT) 15, nitrogen gas outlet 16, base 17, lower loading tie rod 18.

[0020] Wherein, the lower loading rod 18 and four guide columns 2 are fixed on the base 17, and the other end of the guide column 2 is connected with the beam 13; the two ends of the beam lifting device 11 are respectively fixed on the base 17 and the beam 13, and the beam can be adjusted 13 moves up and down along the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com