Experiment segment based on fusion and fission mixed pile water cooling cladding layer and experiment method of experiment segment

A water-cooling pack and experimental section technology, applied in educational appliances, instruments, teaching models, etc., can solve the problems of high temperature and sealing of the rod bundle channel, and achieve the effect of good sealing, preventing deformation and bending, and ensuring sealing performance.

Inactive Publication Date: 2015-01-07

XI AN JIAOTONG UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, its measuring medium is oil, which cannot be applied to water. Since it uses glass rod bundles, it cannot solve the high temperature and sealing problems in the rod bundle channels.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

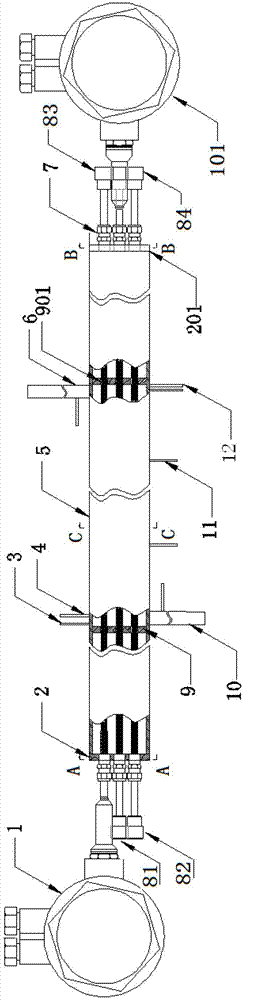

[0052] When the system is running, water flows in from the inlet pipe 10 of the experimental section, skims the seven heating rods in the high-temperature-resistant stainless steel pipe 5 longitudinally, and flows out from the outlet pipe 6.

[0053] The main parameters measured and calculated by the data acquisition system are as follows:

[0054] Water inlet temperature t in =16.46℃,

[0055] Water outlet temperature t out =20.04℃,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

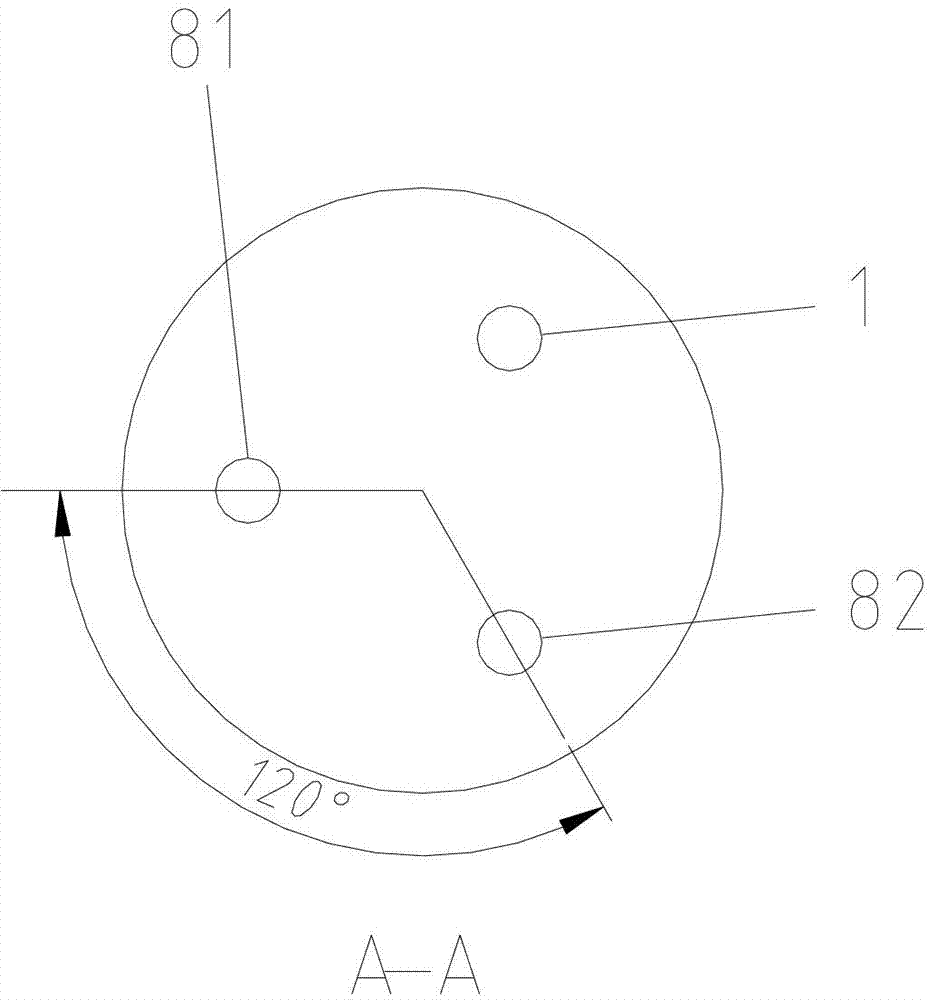

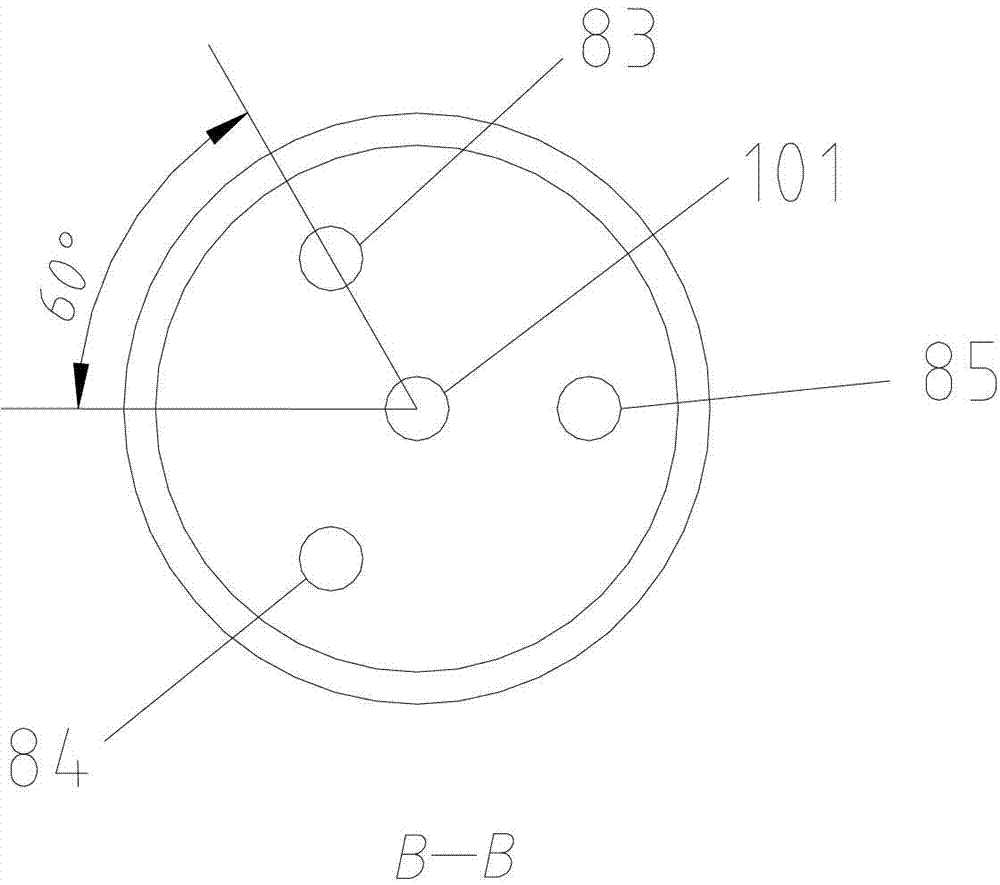

The invention relates to an experiment segment based on a fusion and fission mixed pile water cooling cladding layer and an experiment method of the experiment segment. The experiment segment comprises a high-temperature resistance stainless steel pipe, an electric heating rod with a thermocouple at the inside, an electric heating rod without a thermocouple, cover plates, separation plates, pressure taking pipes and an inlet and outlet branch pipe, wherein the electric heating rods are respectively assembled in the high-temperature resistance stainless steel pipe, the cover plates are welded at the two ends of the electric heating rods, two stainless steel separation plates are welded in the high-temperature resistance stainless steel pipe, three armored thermowells are simultaneously welded outside the high-temperature resistance stainless steel pipe, the pressure taking pipes are respectively welded on the outer wall surface of the high-temperature resistance stainless steel pipe, three heating rods are placed at the left end of the experiment segment, four heating rods are placed at the right end, and the heating rods at the left end and the heating rods at the right ends are in crossed placement. By aiming at the experiment segment of the fusion and fission mixed pile water cooling cladding layer model manufacture, the flowing heat exchange condition under the structure is simulated, the experiment segment can be used at high temperature and high pressure, the sealing insulation performance is good, the results can be easily measured, the structure is compact, and the experiment segment is suitable for being assembled onto a nuclear reactor thermal hydraulic high-temperature and high-pressure experiment loop.

Description

technical field [0001] The invention relates to the technical field of fusion and fission mixed reactor equipment experiments, in particular to an experimental section based on a fusion and fission mixed reactor water-cooled cladding and an experimental method thereof. Background technique [0002] The nuclear reactor thermal hydraulic high temperature and high pressure experimental circuit is a platform for experimental research on the two-phase boiling characteristics of water. For the water-cooled cladding test section of a fusion-fission hybrid reactor, there are many different technologies. [0003] For example, Chinese patent 201120359365.5 provides a device for measuring the temperature of passageways of closely arranged thin rod fuel assemblies. It includes positioning components and thermocouple components, but it is only suitable for the temperature measurement of the fuel bundle channel of the pressurized water reactor, and is not suitable for the measurement of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G09B23/20

Inventor 田文喜汪周建蔚江涛秋穗正苏光辉巫英伟

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com