Comprehensive wiring LED device

An integrated wiring and LED circuit technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increased labor costs, easy to break, unstable wire positioning, etc., to reduce material costs, manufacturing costs, and labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention solves the deficiencies in the prior art and provides a structural solution for LED equipment, which is beneficial to the positioning of welding wires. As illustrated and discussed below, the wires can be properly secured to prevent them from being easily disconnected during the manufacturing process, thereby providing a more durable LED device.

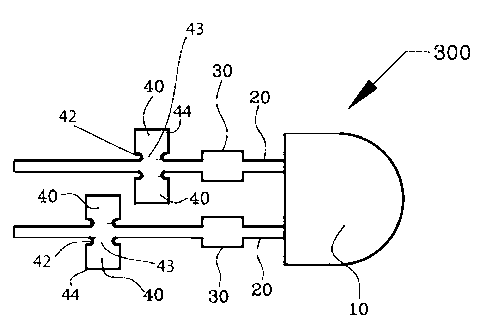

[0029] image 3 and Figure 4 An integrated wiring LED assembly 300 is shown, the structure covers the advantages of the traditional LED wiring connection in the prior art mentioned above, and the structural design is improved.

[0030] The integrated wiring LED assembly 300 includes at least one light emitting diode circuit for emitting light, and the circuit is conventionally packaged in a transparent casing to form the LED body 10 . The integrated wiring LED assembly 300 has a set of at least two partially conductive support legs 20 to provide an electrical connection between the LED circuit encapsulated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com