Method for calibrating current in motor-driven control system of electric automobile

A technology for motor drive control and electric vehicles, applied in the direction of motor parameter estimation/correction, etc., can solve problems affecting the accuracy of calculated current, reduce control errors and ensure feedback accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

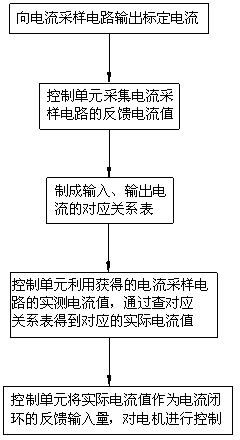

[0020] Such as figure 1 As shown, the current calibration method in the electric vehicle motor drive control system of this embodiment includes the following steps:

[0021] A: Use the regulated power supply to output the calibration current of multiple calibration current points to the current sampling circuit in the motor drive control system, and the calibration current points are evenly distributed within the range of the current sensor in the current sampling circuit;

[0022] B: using the control unit in the motor drive control system to collect the feedback current value corresponding to each calibration current point of the current sampling circuit;

[0023] C: Subtract the corresponding calibration current value from the feedback current value to obtain the deviation of the input and output current of the current sampling circuit;

[0024] D: Record the corresponding relationship between the calibration current value corresponding to each calibration current point, t...

Embodiment 2

[0028] The current calibration method in the electric vehicle motor drive control system of the present embodiment includes the following steps:

[0029] A: Use the regulated power supply to output the calibration current of multiple calibration current points to the current sampling circuit in the motor drive control system, and the calibration current points are evenly distributed within the range of the current sensor in the current sampling circuit;

[0030] B: using the control unit in the motor drive control system to collect the feedback current value corresponding to each calibration current point of the current sampling circuit;

[0031] C: Subtract the corresponding calibration current value from the feedback current value to obtain the deviation of the input and output current of the current sampling circuit;

[0032] D: Record the corresponding relationship between the calibration current value corresponding to each calibration current point, the feedback current v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com