Feedback device for side propeller

A feedback device and thruster technology, applied in ship propulsion, propulsion components, mechanical gear transmission and other directions, can solve the problems of low accuracy of the feedback device, inconvenient installation and debugging, etc., to achieve convenient installation and debugging, ensure accuracy, and improve feedback accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

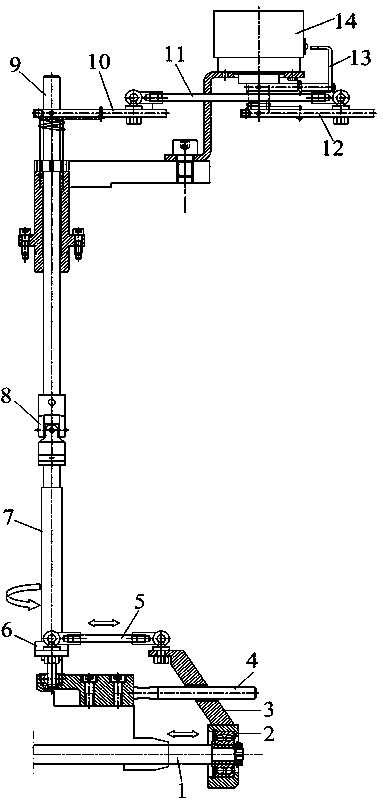

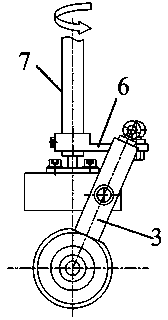

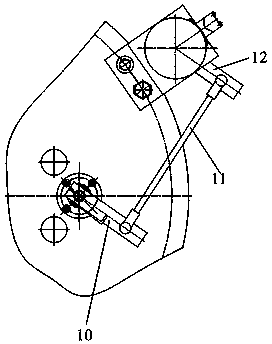

[0018] Such as figure 1 , figure 2 As shown in the feedback device of the lateral thruster, the paddle shaft 1 is freely rotatably supported on the frame, the end of the paddle shaft 1 is installed with a bearing seat 2 through a lock nut, and the frame above the paddle shaft 1 is fixed with a The paddle shaft is parallel to the guide rod 4, the guide rod 4 is covered with a slider 3, one end of the slider 3 is fixedly connected to the bearing seat 2, and the other end of the slider 3 is connected to one end of the first connecting rod 5 through a joint bearing. Hinged, the other end of the first connecting rod 5 is hinged with the first crank 6 through the joint bearing, the first crank 6 is fixedly connected with the lower rod 7, the lower rod 7 is rotatably supported on the machine base, the axis of the lower rod 7 Perpendicular to the axis of the paddle shaft 1, the lower rod 7 is connected to the upper rod 9 through a coupling 8, the upper rod 9 is rotatably supported o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com