Electrostatic image developing toner particles and developer

An electrostatic image development and toner technology, which is applied in the directions of developers, electrographics, instruments, etc., can solve the problems of difficult toner particles, unstable dispersion state, uncertain shape, etc., and achieve excellent development stability, The effect of excellent low temperature fixability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

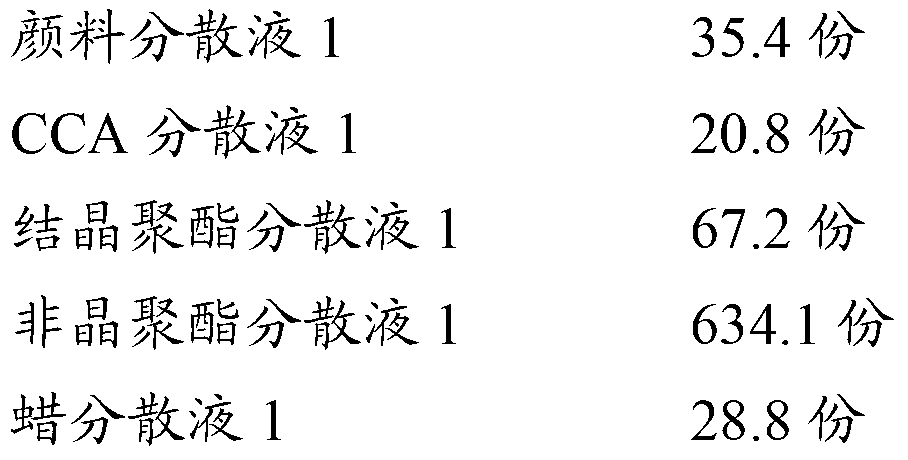

[0062] (1) Preparation of toner samples

[0063] In a laboratory controlled at 25°C and 55%RH, weigh 15g of toner and place it at 50cm 3 into a sample vial (eg, trade name "SV-50", product of NICHIDEN-RIKA GLASS CO., LTD.), and then the vial is closed with a cap. The sample bottle was passed through a YAYOI shaker (model: YS-LD, product of YAYOI CO., LTD.) at 2.5S -1 Shake for 5 minutes. Here, the shaker is adjusted so that its legs move forward 15 degrees and backward 20 degrees (when the shaker's directly above position (vertical) is considered 0 degrees). The vial was fixed to a fixing holder (holder) attached to the end of the post (the cap of the vial was fixed to the center of the post and its extension). After shaking, the sample bottle was carefully removed so that the compacted toner did not break.

[0064] Next, the capped vial was stored for 1.5 hours in a high temperature bath controlled at 50°C or an environmental chamber controlled at 50°C (for example, "THER...

Embodiment

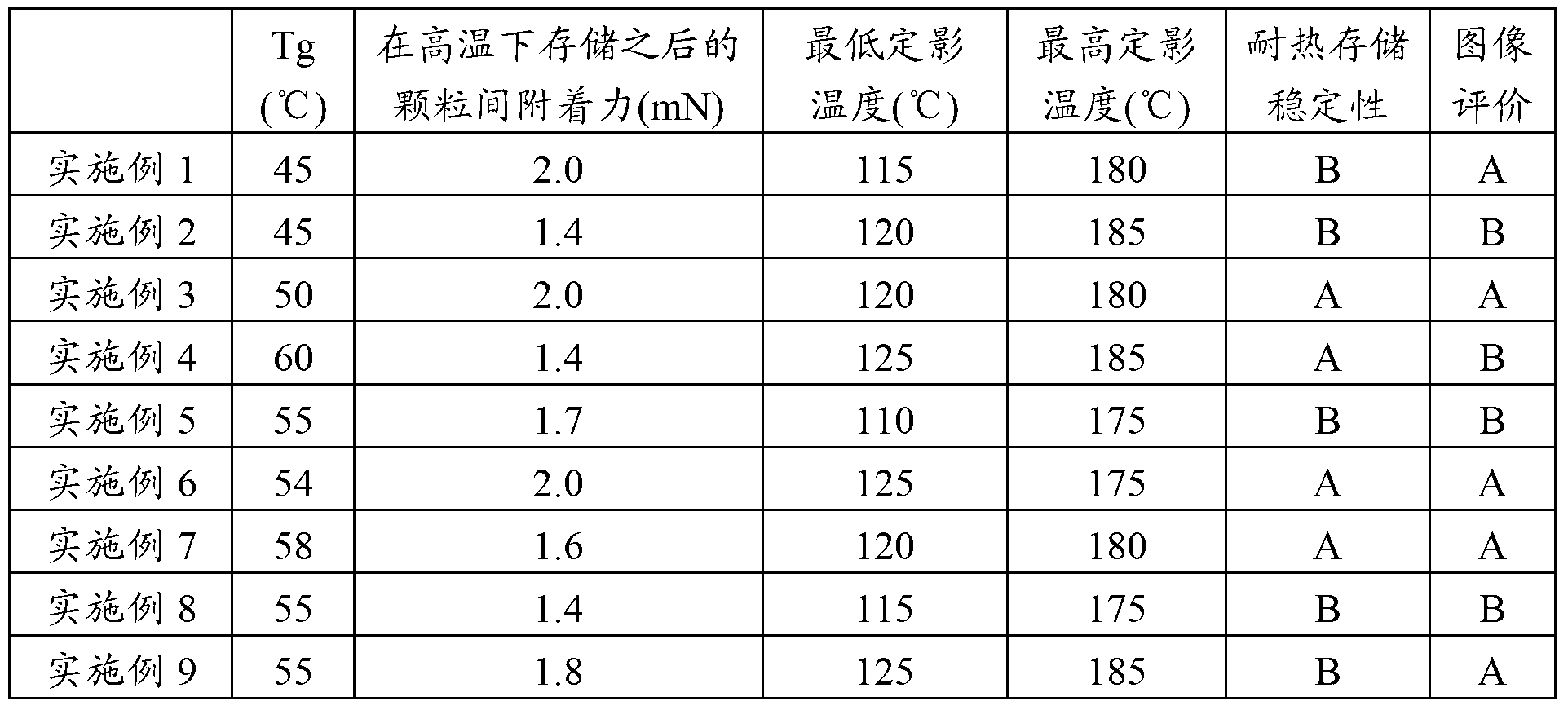

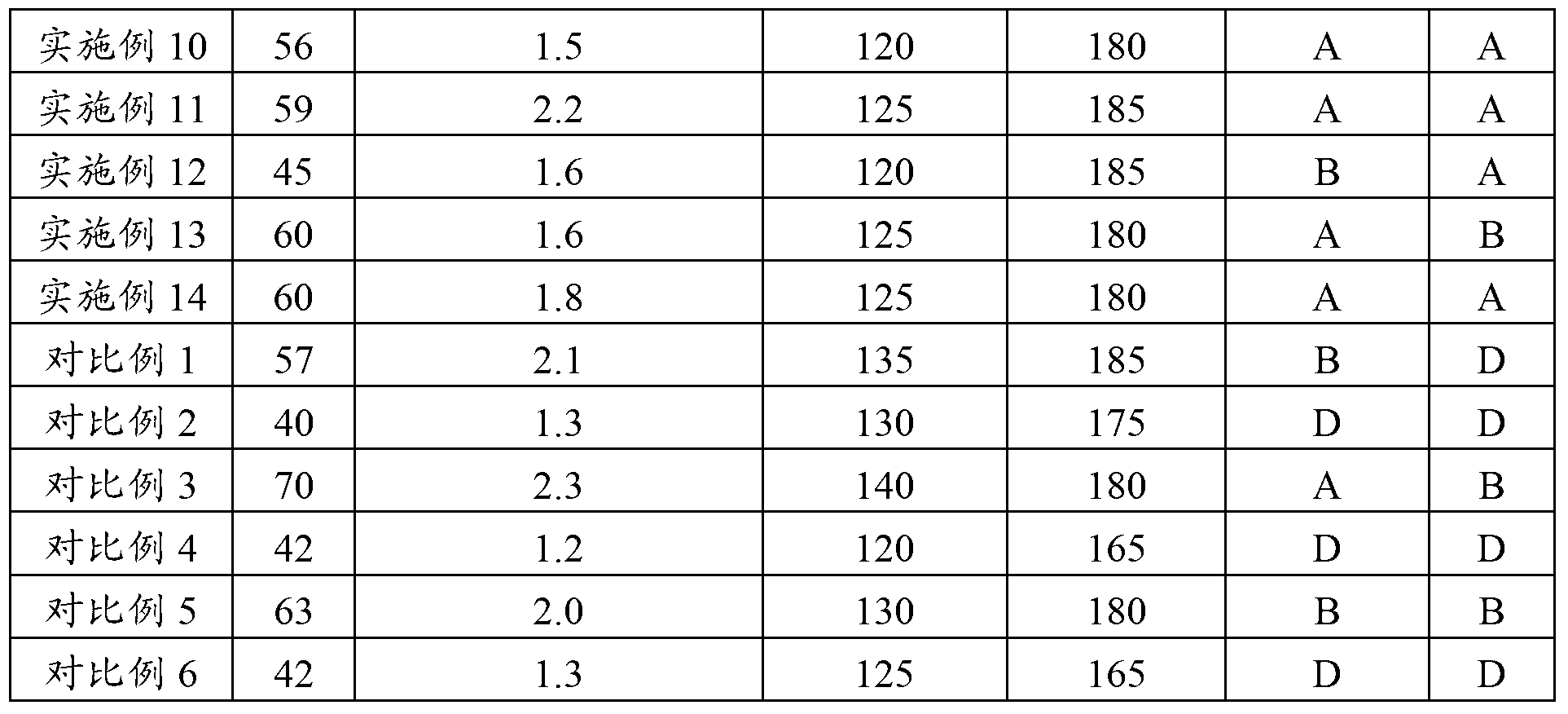

[0257] Next, the present invention will be described in more detail by way of examples, which should not be construed as limiting the present invention thereto. In the following examples, the unit "part" means "part by mass".

[0258] -Synthesis of Crystalline Polyester Resin 1-

[0259] Add 1,10-sebacic acid (2,120 g), 1,8-octanediol (1,000 g), 1,4- Butylene glycol (1,520 g) and hydroquinone (3.9 g) were then reacted at 180° C. for 10 hours. After that, the reaction mixture was reacted at 200° C. for 3 hours and further reacted at 8.3 kPa for 2 hours, whereby Crystalline Polyester Resin 1 was produced. Crystalline polyester resin 1 thus produced was found to have a melting point of 67° C. as measured by the method described above.

[0260] -Synthesis of Crystalline Polyester Resin 2-

[0261] Into a 5 L four-necked flask equipped with a nitrogen introduction tube, a drain tube, a stirrer and a thermocouple were charged 1,12-dodecanediol (2,500 g), 1,8-suberic acid (2,330 ...

Embodiment 2

[0309] The procedure of Example 1 was repeated except that [Crystalline Polyester Dispersion Liquid 1] was changed to [Crystalline Polyester Dispersion Liquid 2], thereby obtaining [Toner 2]. [Toner 2] was found to have: a Tg of 45° C., and an inter-toner particle adhesion of 1.4 mN measured after it had been stored at a high temperature.

[0310] Note that the emulsified slurry, dispersed slurry, and base toner obtained in Example 2 are referred to as [emulsified slurry 2], [dispersed slurry 2], and [base toner 2], respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com