Chain-drum type precise dibbling machine

A technology of hole sowing device and chain drum type, which is applied in the field of chain drum type precision hole seeding device, can solve the problems of easy soil plugging, lack of seedlings and broken ridges, poor adaptability and other problems, and achieves wide application range, no seed damage, and convenient The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

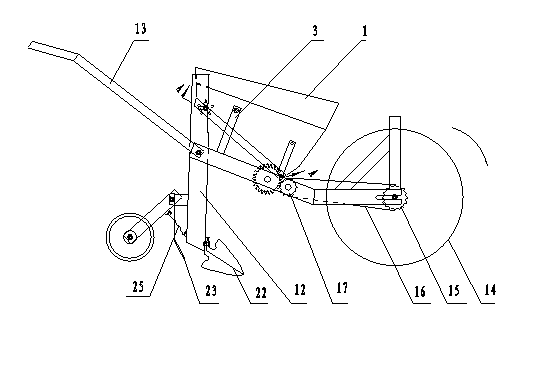

[0022] In the embodiment 1 shown in 1-4, the ground wheel 14 is fixedly installed on the frame 2, and the force acts on the thrust handle 13, and the machine

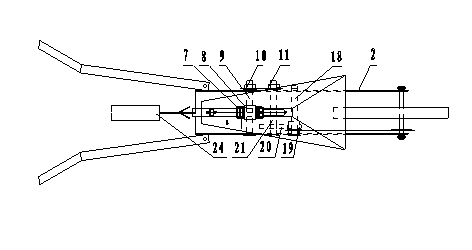

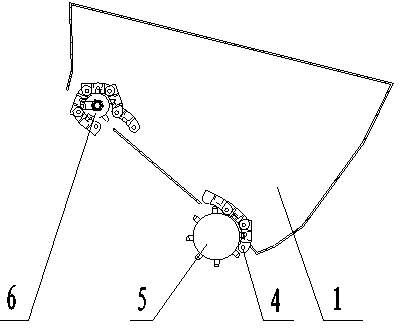

[0023] The device rotates clockwise along the direction indicated by the arrow. The driving sprocket 15 is fixedly installed on the axle of the ground wheel 14 and rotates clockwise synchronously with the ground wheel 14. The driving sprocket 15 transmits power to the driven sprocket through the chain 16. 17. The sprocket shaft 18 runs through the driven sprocket 17 and the driving gear 19 and is fixedly connected with the frame 2. The driven sprocket 17, the driving gear 19 and the ground wheel 14 rotate clockwise in the same direction, and the driving gear 19 rotates to drive the driven gear 20 Rotate, the driven gear 20 gears rotate counterclockwise, the gear shaft 21 runs through the driven gear 20, the main chain cylinder sprocket 5 and the main reseeding sprocket 11 and is fixedly connected with the frame 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com