Drying equipment and drying process thereof

A technology of drying equipment and drying machine, which is applied in the direction of drying and preserving seeds, which can solve the problems of taking a lot of time, increasing investment costs and energy consumption indicators, and achieves small footprint, high heat utilization rate, and low moisture content. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

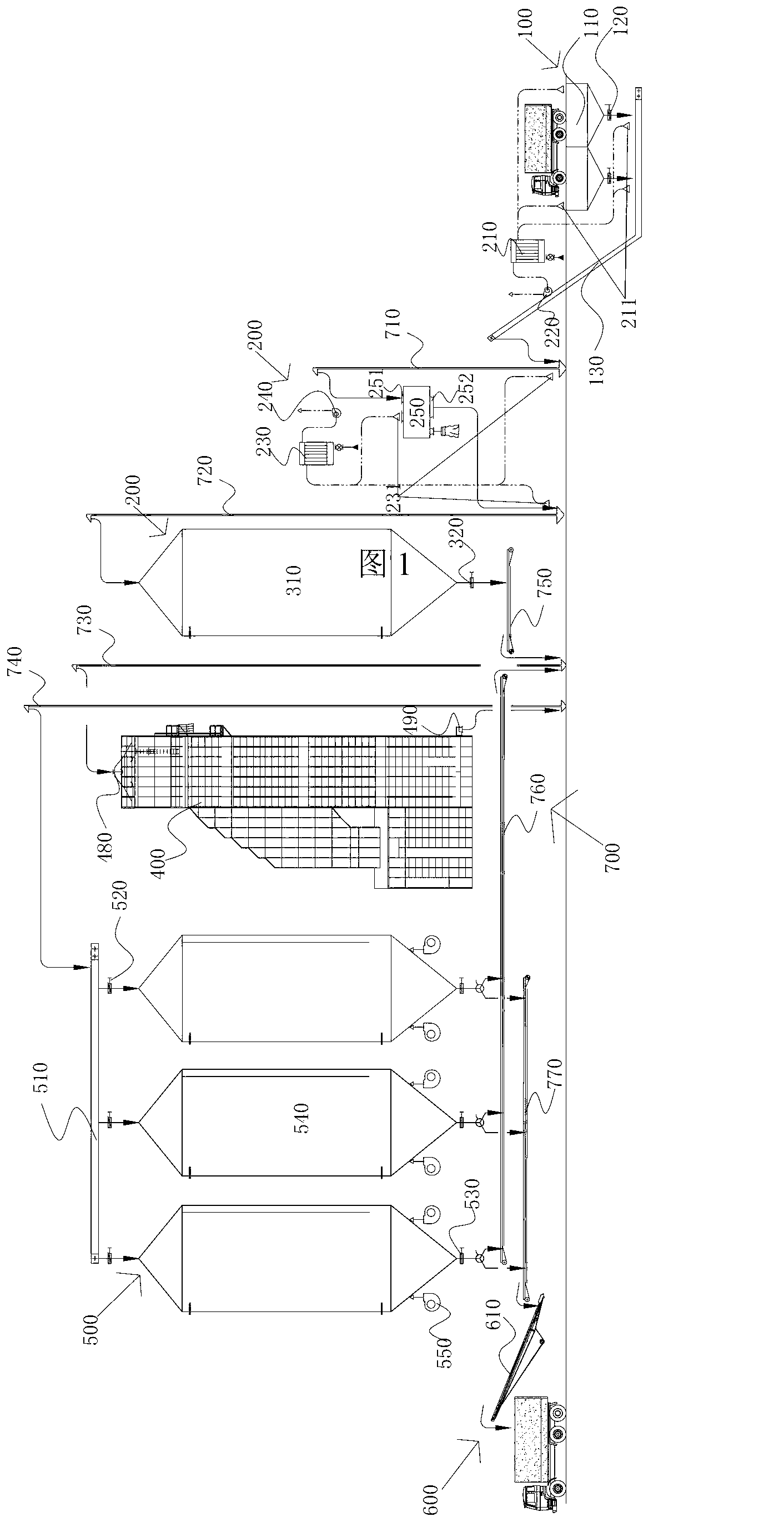

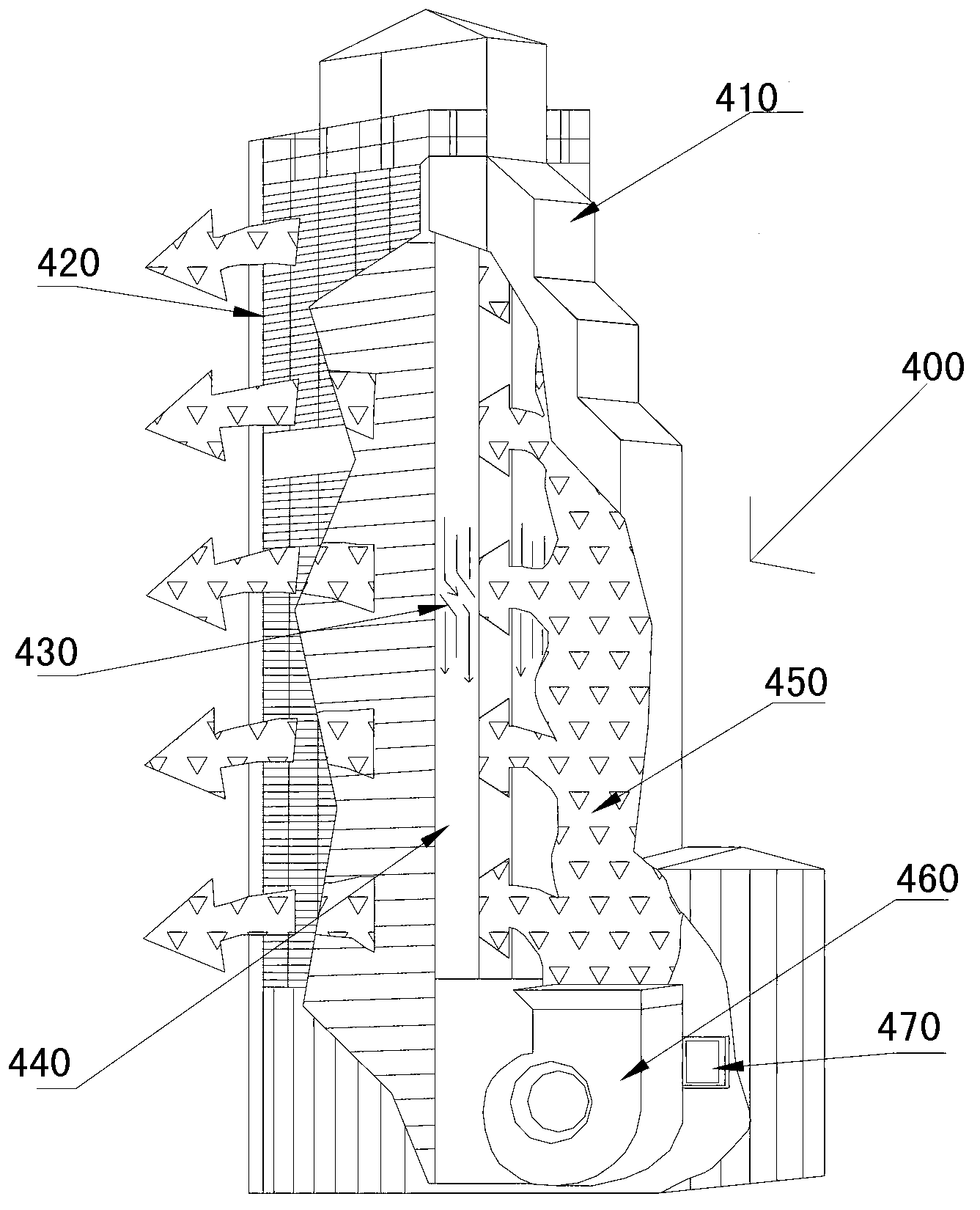

[0036] figure 1 It is an overall structural diagram of the present invention, figure 2 It is the structure diagram of the dryer, such as figure 1 and figure 2 shown. The drying technology adopted in the present invention mainly includes two aspects: equipment aspect and system aspect.

[0037] From the perspective of equipment, a drying equipment includes: a grain unloading unit 100 , a cleaning and dust removal unit 200 , a drying front unit 300 , a dryer 400 , a slowing unit 500 and a warehouse delivery unit 600 sequentially connected through a transmission unit 700 .

[0038] The grain unloading unit 100 includes: a grain unloading pit 110, a grain unloading gate 120, and a curved scraper 130. The grain unloading unit 100 is a pit-like structure with a curved scraper 130 at the bottom and a grain unloading gate 120 above the bottom. A grain unloading pit 110 is provided above the grain unloading gate 120 , and the curved scraper machine 130 is connected to the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com