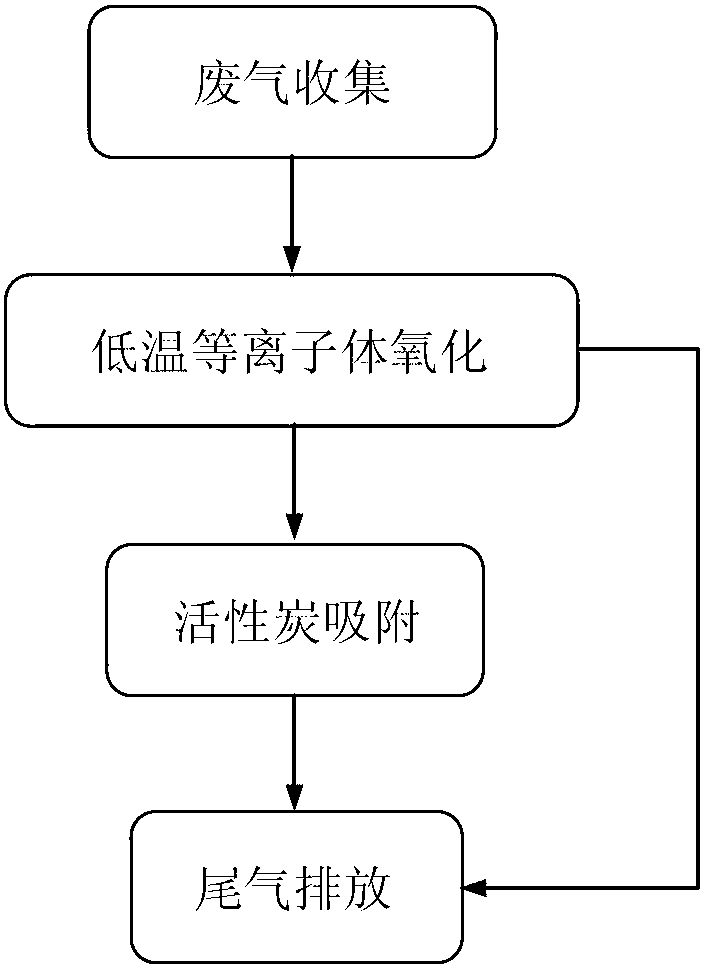

Method for treating chlorohydrocarbon-containing gas by low-temperature plasma

A low-temperature plasma and plasma technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, to achieve the effects of mild reaction conditions, short process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

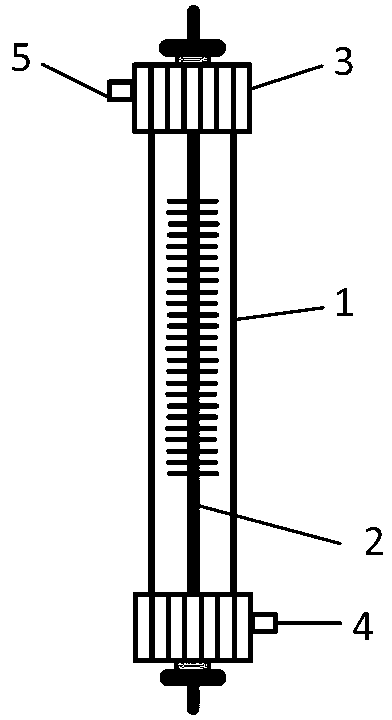

Image

Examples

Embodiment 1

[0025] The plasma reactors in the low-temperature plasma unit are connected in parallel, and the low-temperature plasma unit is connected to the activated carbon adsorption unit. The exhaust gas containing chlorinated hydrocarbons enters the plasma reactor through the induced draft fan. The high-voltage power supply is turned on and the applied voltage is adjusted. The fixed injection energy is 100J / L, for waste gas containing methyl chloride, vinyl chloride, carbon tetrachloride, when the initial concentration is 100mg / m 3 , when the waste gas flow rate is 100L / min, and the waste gas humidity is 20%, after being treated by two-stage purification units, the removal rate of each chlorinated hydrocarbon can reach more than 98%.

Embodiment 2

[0027] The plasma reactor in the low-temperature plasma unit is connected in parallel, and the low-temperature plasma unit is connected to the activated carbon adsorption unit. The exhaust gas enters the plasma reactor through the induced draft fan, the high-voltage power supply is turned on and the applied voltage is adjusted. The fixed injection energy is 100J / L. For Waste gas containing methyl chloride, vinyl chloride, carbon tetrachloride, when the initial concentration is 500mg / m 3 , when the waste gas flow rate is 150L / min, and the waste gas humidity is 20%, after the two-stage unit purification treatment, the removal rate of each chlorinated hydrocarbon in the waste gas can reach 95%. Under the same conditions, adjust the applied voltage of the high-voltage power supply, increase the injection energy to 150J / L, and the removal rate of each chlorinated hydrocarbon can reach more than 98%.

Embodiment 3

[0029] The plasma reactors in the low-temperature plasma unit are connected in parallel, and the low-temperature plasma unit is connected to the activated carbon adsorption unit. The exhaust gas enters the plasma reactor through the induced draft fan. Turn on the high-voltage power supply and adjust the applied voltage. The fixed injection energy is 100J / L. Chloromethane, vinyl chloride, carbon tetrachloride, chloroform, 1,1,1-trichloroethane, 4-chlorophenol waste gas, when the initial concentration is 1000mg / m 3 , when the exhaust gas flow rate is 150L / min, and the exhaust gas humidity is 20%, after the two-stage unit purification treatment, the removal rate of each chlorinated hydrocarbon in the exhaust gas is 90%. Under the same conditions, only the connection mode between the reactors in the low-temperature plasma unit is changed, and the four plasma reactors in the unit are connected in series. After two-stage unit purification treatment, the removal rate of each chlorinat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap