Manufacturing method of cold roll forming for waveform beam guardrail plate

A technology of cold forming and manufacturing method, which is applied in the field of manufacturing single-beam guardrail panels, and can solve the problems that the manufacturing equipment cannot meet the anti-collision level and cushioning capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 The preferred embodiments of the present invention are described, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0025] Examples of manufacturing methods for cold roll forming:

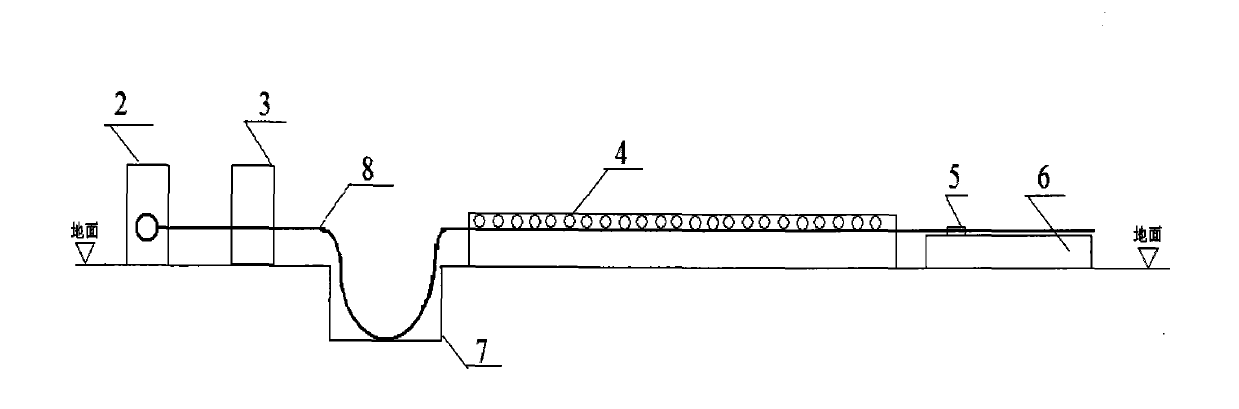

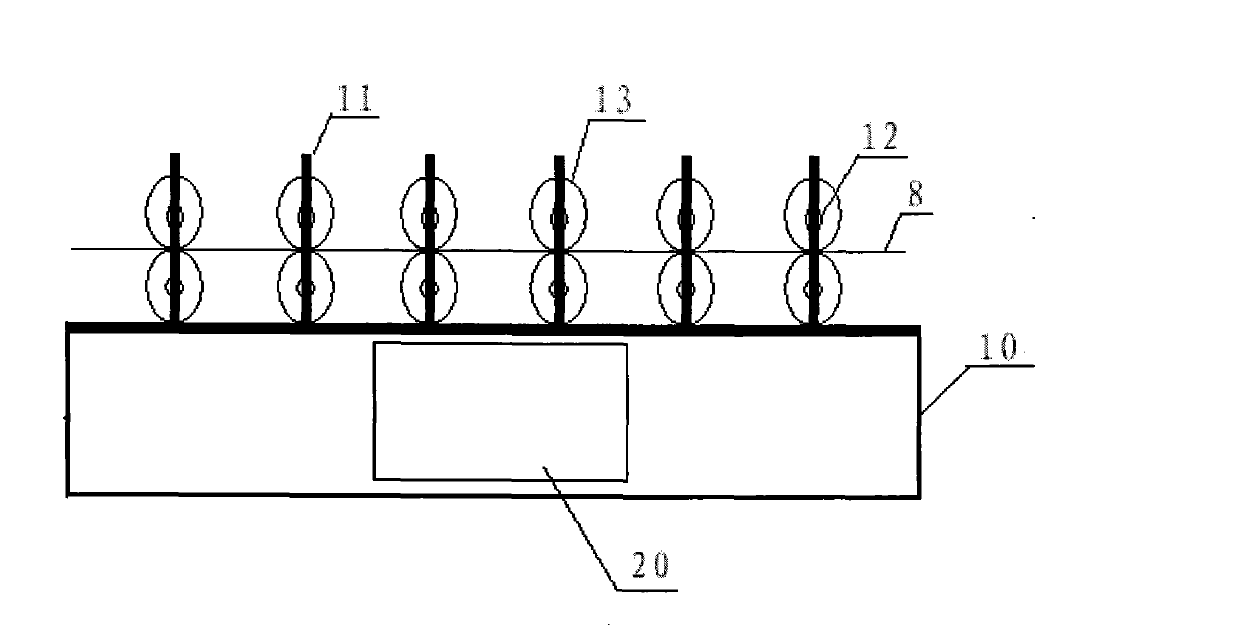

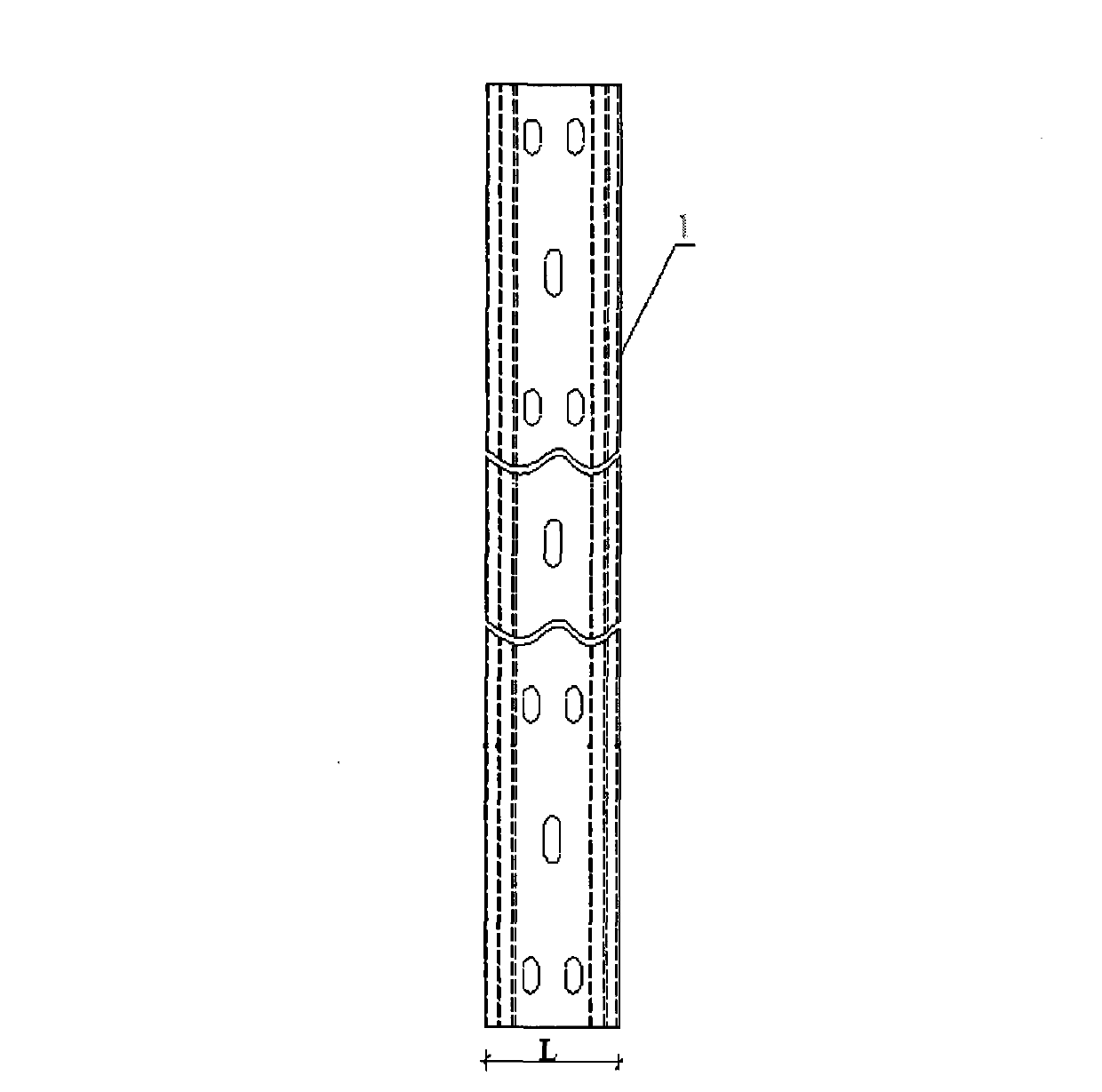

[0026] A cold-formed manufacturing method for a single-wave beam guardrail panel, which is produced by continuous flow of equipment such as a coiled plate fixing frame 2, an edge trimming and punching device 3, a cold bending unit 4, a flying saw 5, and a material receiving table 6, and is fixed on the coiled plate Between the frame and the cold bending unit, a slow material trough 7 is set below the ground to reduce the feeding resistance of the cold bending unit, and to facilitate accurate positioning of the steel plate 8 when feeding. The cold bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com