Lathe center frame auxiliary clamping mechanism

An auxiliary clamping and center frame technology, which is applied in the direction of clamping, metal processing machinery parts, supports, etc., can solve the problems of unable to process the outer circle of the car, and the normal rotation of the moving bolts, etc., to achieve the effect of ensuring normal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

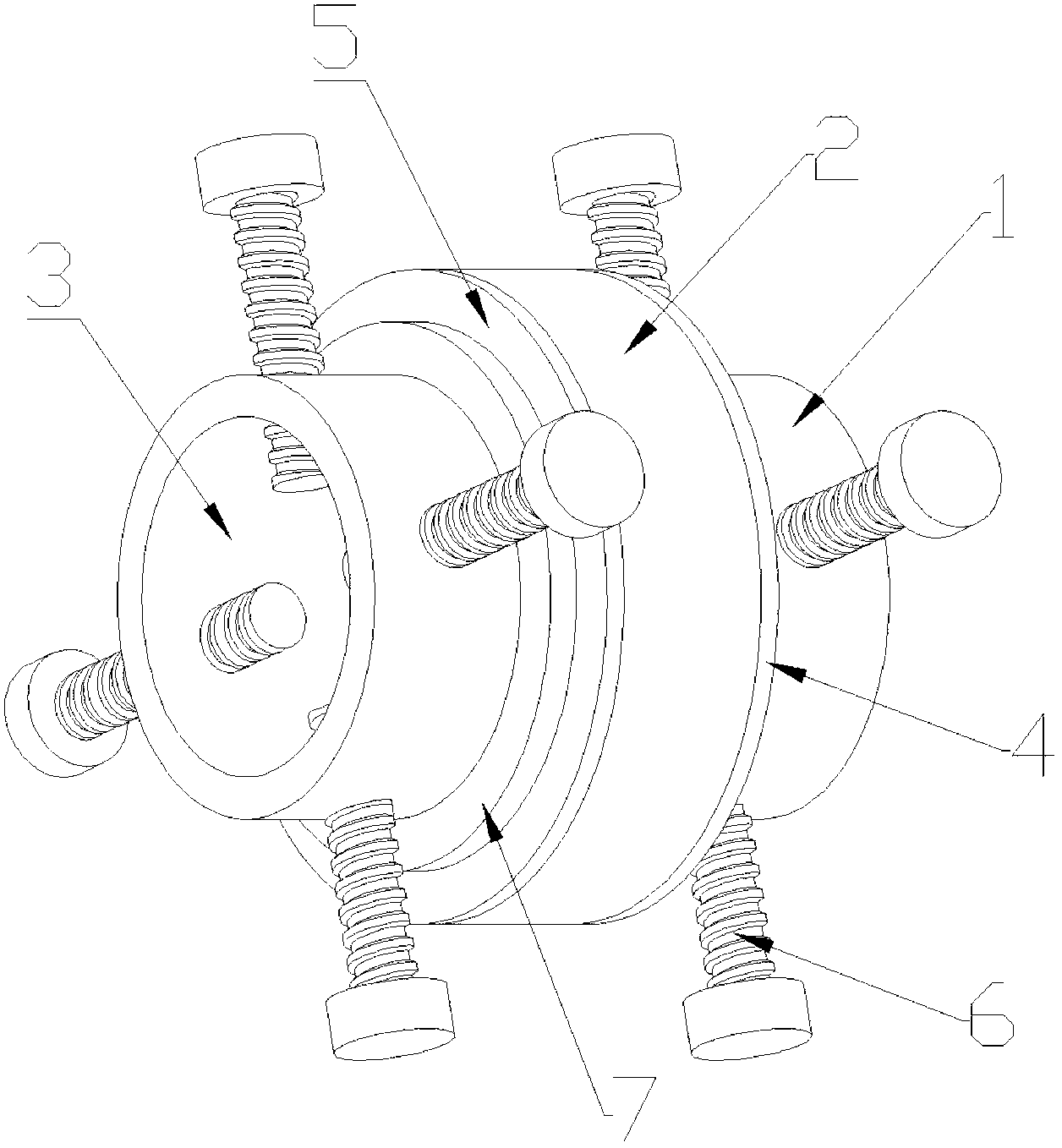

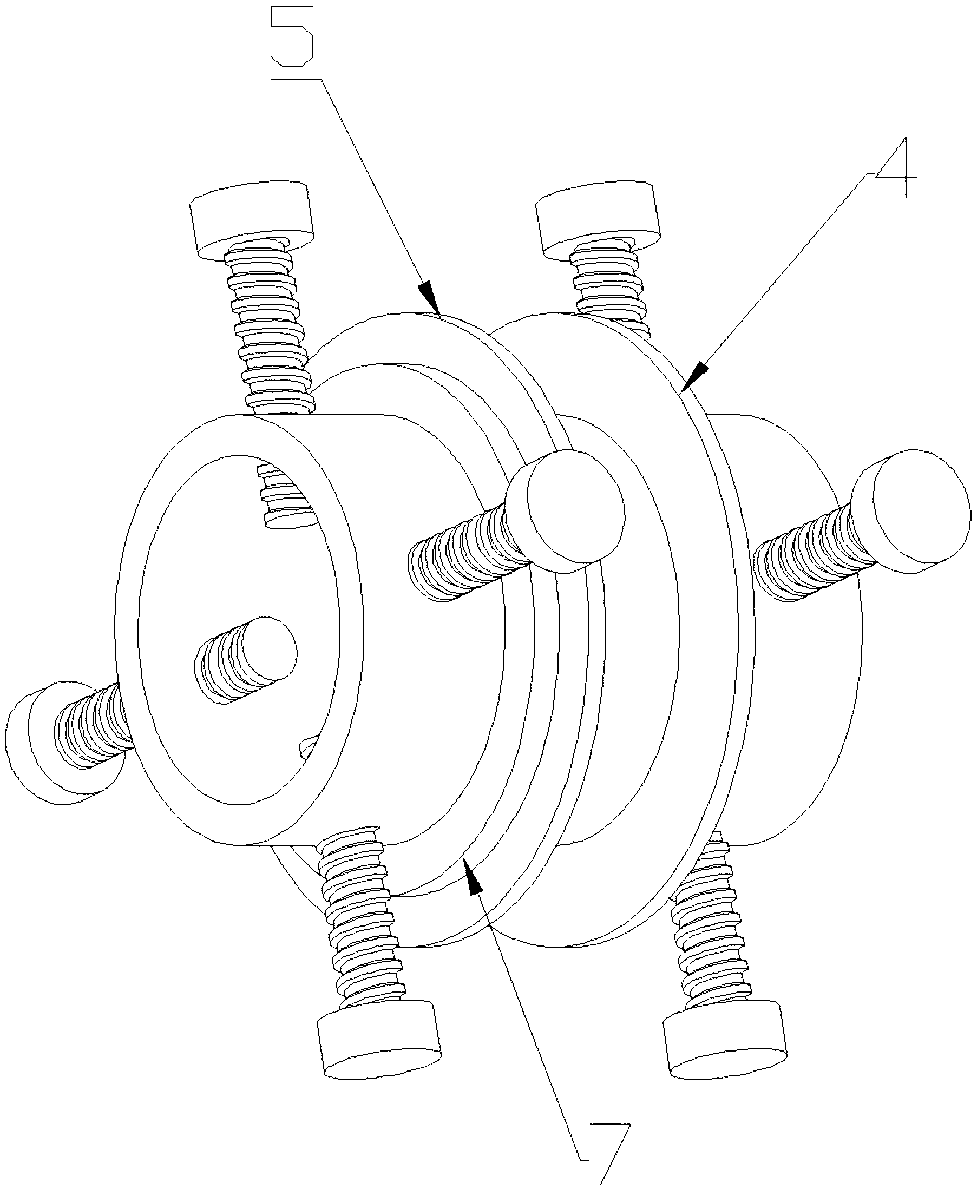

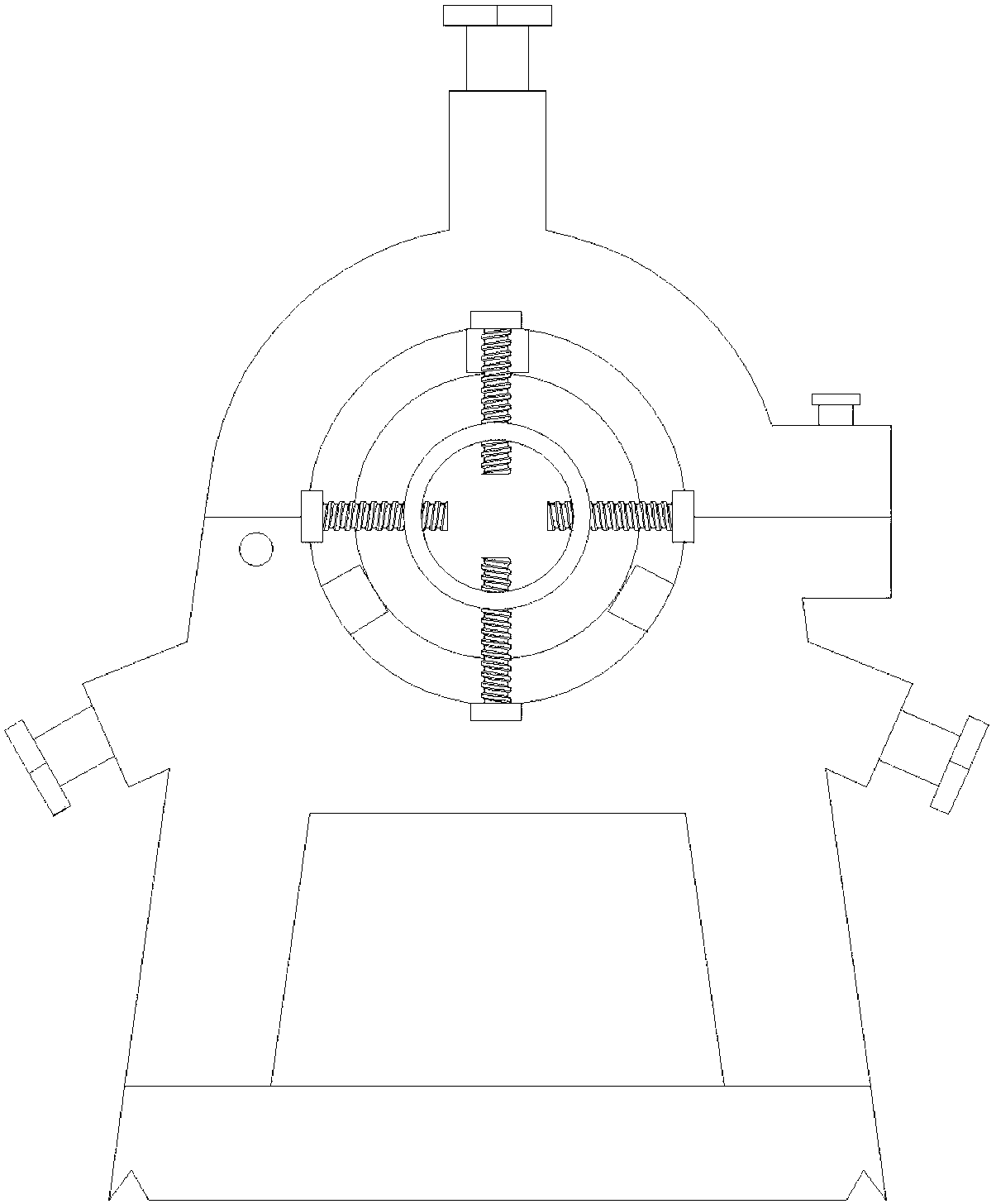

[0021] As shown in the figure, the auxiliary clamping mechanism of the lathe steady frame of the present invention includes a clamping sleeve 1 and a rolling bearing 2 . In this embodiment, the rolling bearing 2 is a ball bearing.

[0022] The clamping sleeve 1 is formed with a sleeve hole 3 for fitting the bolt to be processed, and the clamping sleeve 1 is provided with at least two compression rods 6 whose end faces press the outer circumference of the bolt to be processed. That is to say, the clamping sleeve 1 realizes synchronous rotation with the processed moving bolt by pressing the pressing rod 6 against the processed moving bolt. Of course, other structures can also be used to realize synchronous rotation, such as the way that the sleeve hole 3 is closely matched with the outer peripheral surface of the processed moving bolt to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com