Multi-wire sawing machine

A multi-wire cutting machine and cutting wire technology, applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of cumbersome process, scrapped materials, high work intensity, etc., and achieve the effect of simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

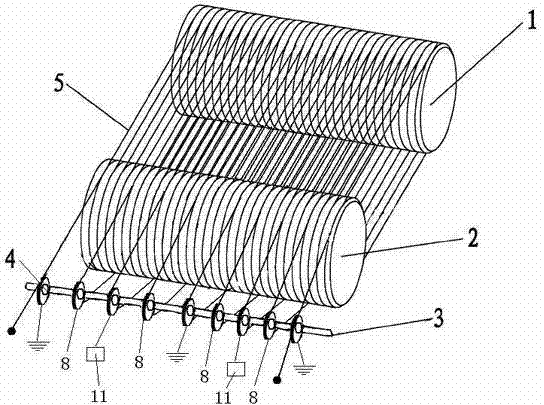

[0019] Such as figure 1 As shown, a multi-wire cutting machine includes a controller 7 and two processing rollers 1 and 2 whose axes are parallel. On the corresponding grooves of the rollers 1 and 2, one of the processing rollers 2 is provided with a fixing rod 3 parallel to the axes of the processing rollers 1 and 2, and on the fixing rod 3, there are multiple gaps with the same spacing between two adjacent wire pulleys. A wire pulley 4,8, the wire groove of each wire pulley 4,8 is all corresponding to the groove on the processing roller 2, and the cutting wire 5 is wound in the wire groove of each wire pulley 4,8, and each wire pulley 4 The number of turns of the cutting wire 5 wound on the wire pulleys 4 and 8 is the same; a voltage detection device for detecting the voltage of the cutting wire 5 is installed on the wire pulleys 4 and 8.

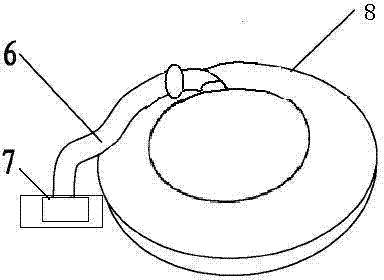

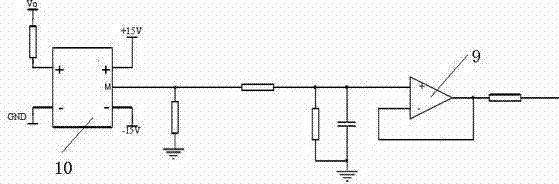

[0020] Such as figure 2 As shown, the voltage detection device includes a voltage sampling circuit arranged in the controller 7, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com