Short-distance plane cam type lifting device of printing working table

A flat cam and lifting device technology, applied in rotary printing presses, printing, printing presses, etc., can solve the problem that operators and designers have high professional knowledge requirements, design machine fine-tuning devices take up a lot of space, and cannot achieve accurate lifting in short distances. Positioning and other issues to achieve the effect of saving operation space, shortening development time, and convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

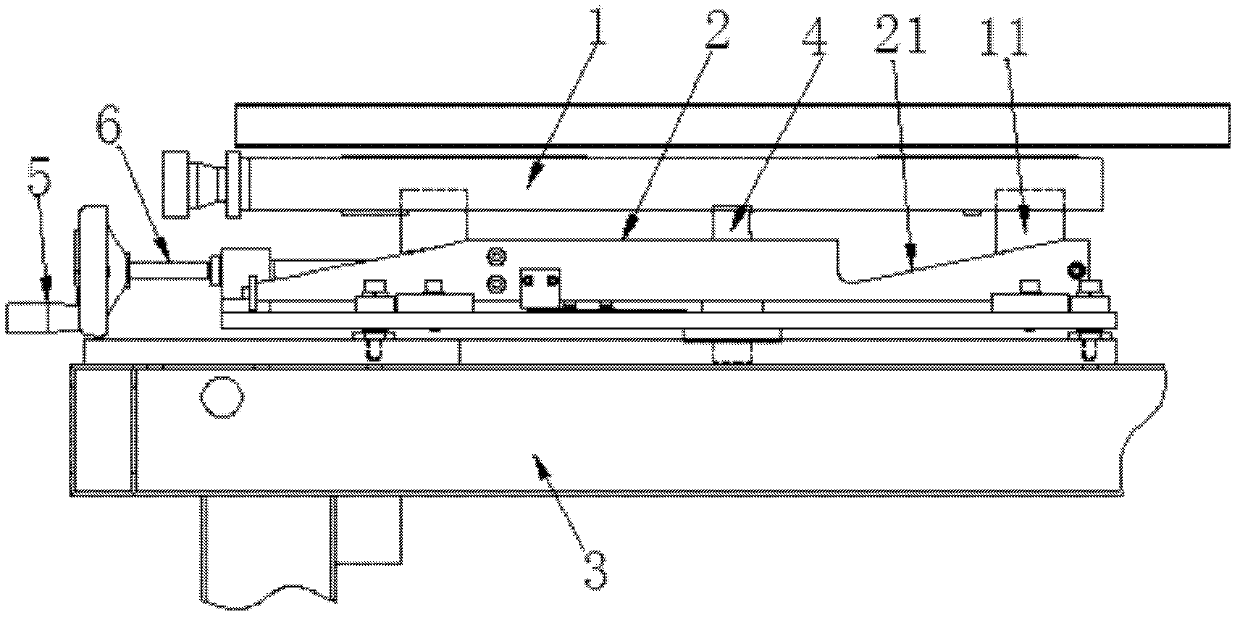

[0011] Embodiment: a short-distance planar cam-type printing table lifting device, including a work table 1, a traction table 2 and a frame table 3, and a lifting mechanism 4, which is composed of a guide post and a guide sleeve. The guide post can be vertically lifted relative to the guide sleeve, the lower end of the guide sleeve is fixed on the upper surface of the rack table 3, and the upper end of the guide post is fixed on the lower surface of the work table 1, and the traction table is connected with A transmission mechanism, the transmission mechanism is connected with a drive mechanism, the drive mechanism can drive the transmission mechanism to drive the traction table to move linearly on the rack table, and the upper surface of the traction table 2 is provided with a slope guide Groove 21, the slope direction of the slope guide groove is consistent with the moving direction of the traction table, the slope guide block 11 corresponding to the slope guide groove is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com