Microgravity experimental system for component performance verification of plate type propellant management device

A technology of plate propellant and test system, applied in the field of microgravity test, can solve problems such as impossible to obtain from foreign literature, no mention of test system design, incomplete data, etc., achieving high test efficiency and economic benefits, wide Application value and promotion prospects, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

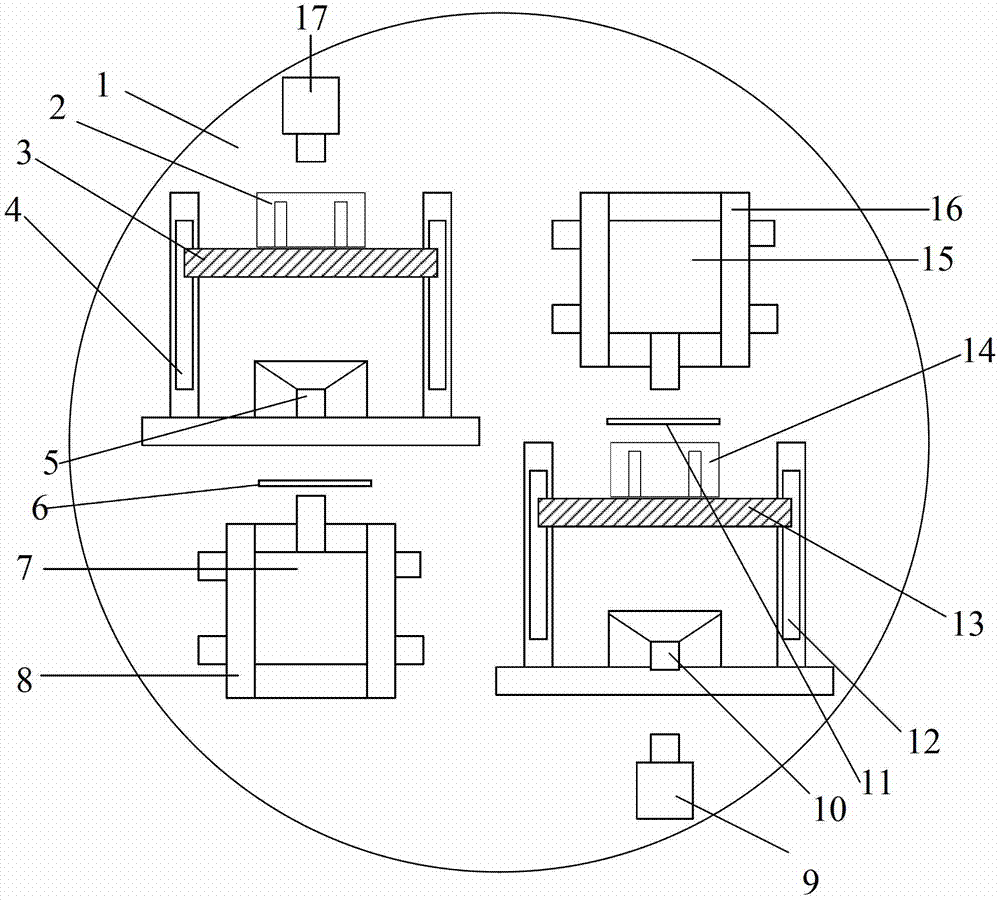

[0018] Such as figure 1 As shown, the present invention includes a test system substrate 1, a height-adjustable test bracket assembly, an image acquisition system, a lighting system, and other parts, and the height-adjustable test bracket assembly, image acquisition system, and lighting system are all on the test system substrate 1 Two sets are arranged symmetrically, and the test system has the ability to conduct microgravity tests of two test models at the same time.

[0019] The test system substrate 1 is a light circular aluminum plate with a wood honeycomb layer inside, which is used to realize the compact installation and fixing of the height-adjustable test bracket components, image acquisition system, lighting system, etc., and realize the test system and microgravity at the same time The test cabin is installed and connected.

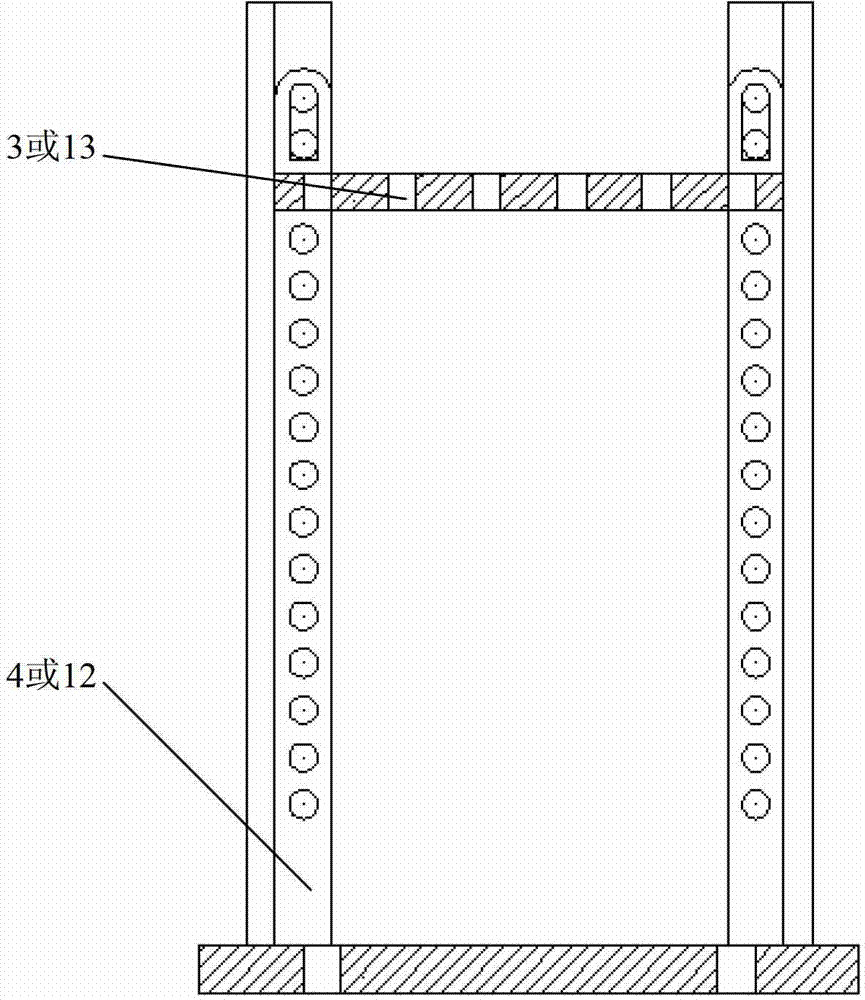

[0020] The height-adjustable test support assembly is made up of two support plates and two supports, and the first support plate 3 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com