Anti-leakage package for bulk explosives and construction method

An anti-leakage and explosive technology, used in packaging, transportation and packaging, containers, etc., can solve the problems of high unit consumption, blasting accidents, large block size, etc., to ensure blasting effect, prevent blasting accidents, and prevent blasting accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

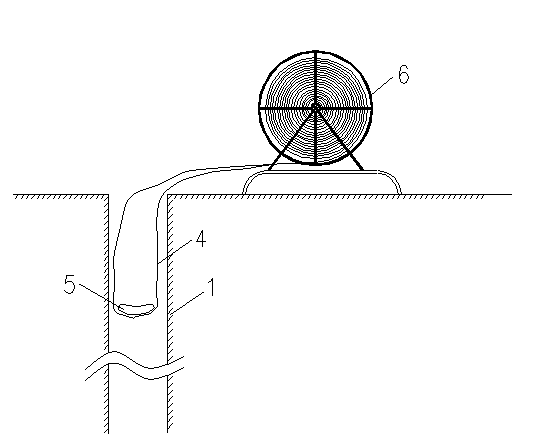

[0011] The cylindrical packaging with a thickness of 0.12mm is made of flame-retardant and anti-static flexible materials, and the inner surface of the special anti-leakage packaging for bulk explosives is coated with a conductive coating to prevent the accumulation of static electricity during the charging process. During the production process, the special anti-leakage packaging ring for bulk explosives is placed on the special anti-leakage packaging rack for bulk explosives for standby.

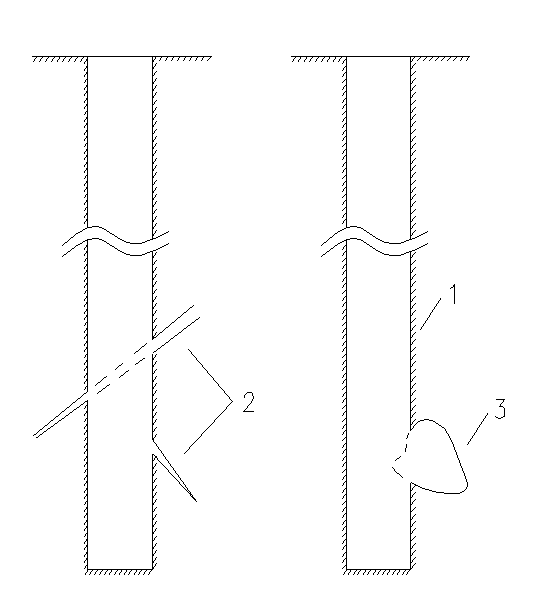

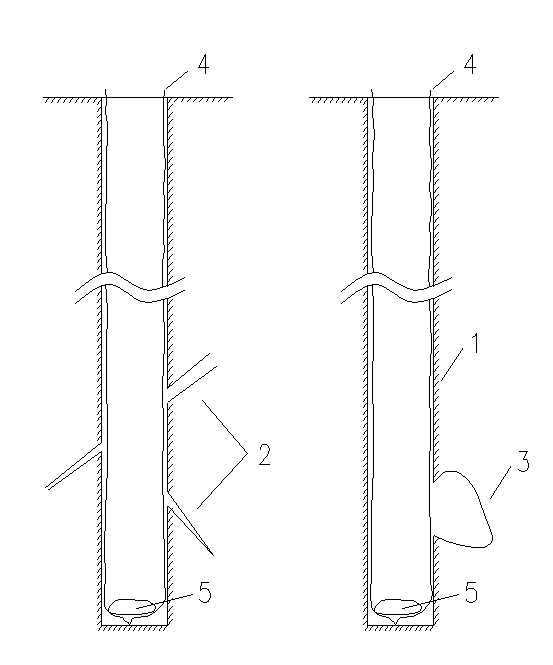

[0012] During construction in multi-porous mines or objects to be blasted, the anti-leakage special package 4 for bulk explosives is placed inside the blasthole 1 to prevent the explosives from penetrating into the cracks 2 or karst caves 3 . The blast hole 1 is first inspected using a measuring hole device. If the depth of the blast hole is inconsistent with the design depth, re-drilling or backfilling should be performed to make the blast hole depth meet the design requirements; if there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com