A fully automatic food tray machine

A fully automatic, tray-arranging machine technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of threatening the personal safety of operators, increasing production costs, and low labor efficiency, so as to protect personal safety, save production costs, The effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

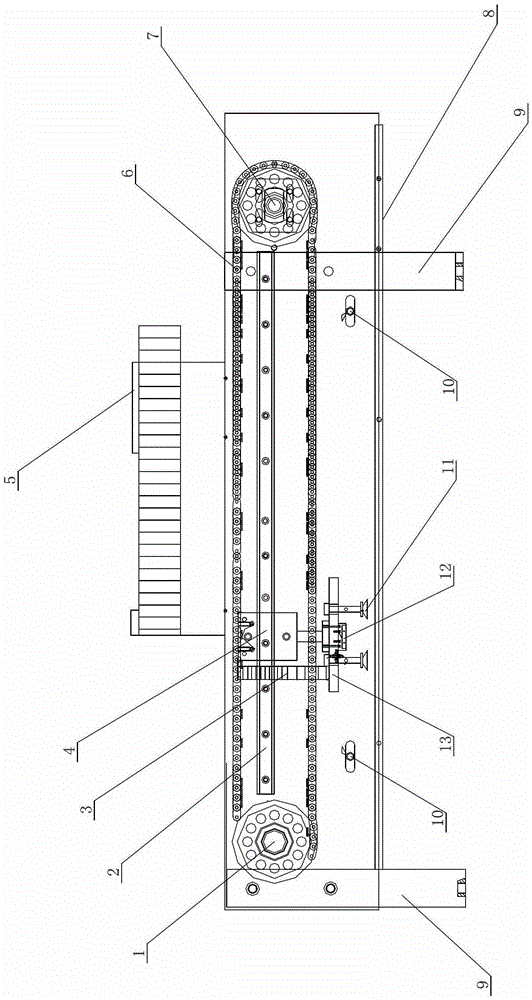

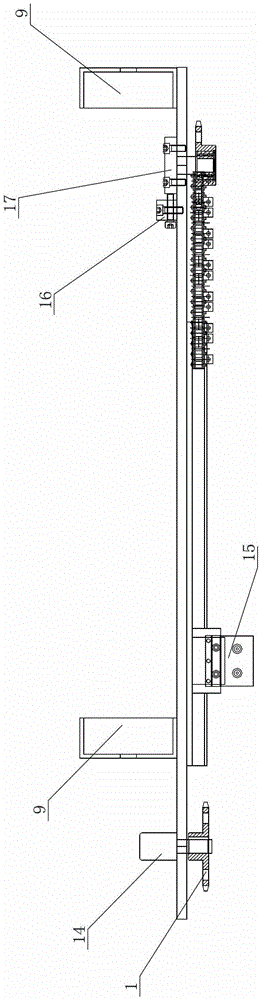

[0021] Such as figure 1 , figure 2 As shown, an automatic food arranging machine includes a frame 9, a drag chain bracket 5 is installed on the upper part of the frame 9, and a drag chain mechanism is installed on the drag chain bracket 5. The upper part of the rack 9 is equipped with a plate arrangement mechanism, which is movably installed on the upper part of the rack, and the lower part of the rack is equipped with a code plate rack 8 corresponding to the plate arrangement mechanism. The code plate rack 8 is movably installed in the rack Lower part. Proximity switches 10 are respectively installed on both sides of the frame, and the proximity switches 10 are at both ends of the stroke of the plate-discharging mechanism, and the proximity switches are electrically connected with a control device.

[0022] In this embodiment, the platoon mechanism includes a platoon device and a power mechanism connected with the platoon device. The disc mechanism includes a cylinder 4 movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com