Alumina high pressure dissolution dilution ore slurry exhaust steam recovery method

A technology of high-pressure stripping and spent steam recovery, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of poor operation effect, exhausting of spent steam, waste of heat energy, etc. , the effect of slowing down the rate of scarring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

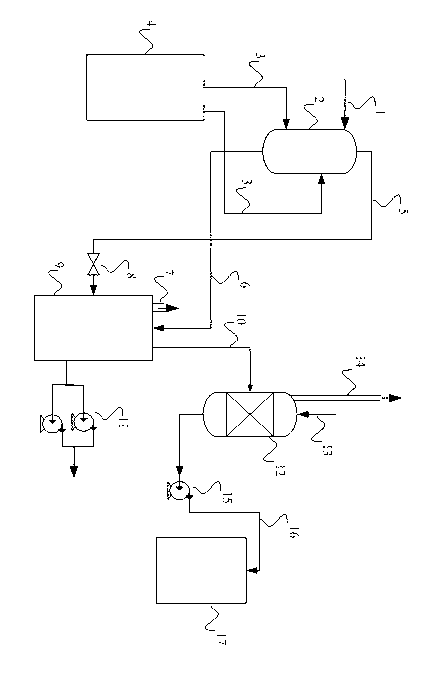

[0011] A method for recovering exhaust steam from high-pressure leaching and diluting alumina slurry. The recovery process adopts direct heat exchange between water and low-pressure exhaust steam with alkali. The heat exchange device used is a tray-type large-channel heat exchanger; its dilution tank exhaust steam After entering the hot water tank, the exhaust steam is connected to the heat exchange device to transport the exhaust steam to the heat exchange device; the low-temperature water that directly exchanges heat with the exhaust steam enters from the top of the tray type large channel heat exchanger, with alkali low pressure Exhaust steam enters from the side wall of the middle of the tray-type large-channel heat exchanger. The trays of the tray-type large-channel heat exchanger can make the water to be heated form a water curtain, and the exhaust steam rises and the water drops for countercurrent heat exchange. The hot water after the waste heat is recovered is discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com