Weather-proof injection-type bar-planting adhesive tube based on acrylic epoxy resin as well as preparation method and use method thereof

A kind of technology of acrylic epoxy resin and planting rubber hose, applied in the direction of modified epoxy resin adhesive, adhesive additive, non-polymer adhesive additive, etc. High, poor resistance to heat and humidity, etc., to achieve fast curing speed, strong corrosion resistance, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

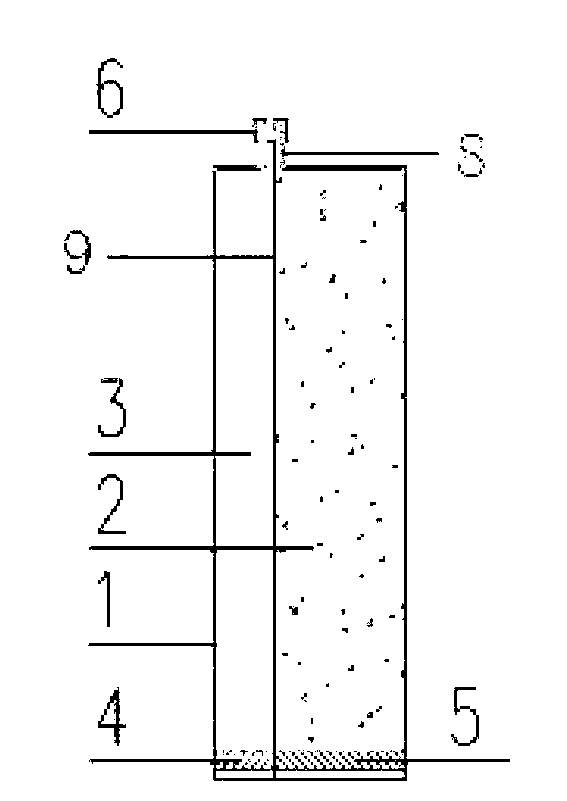

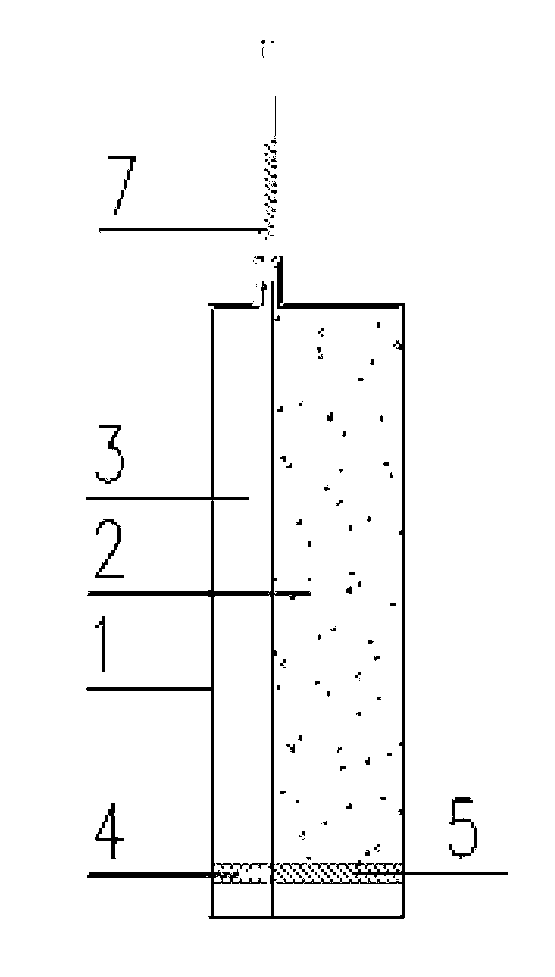

[0026] Such as figure 1 As shown, it is the state of the weather-resistant injection-type rebar-planting rubber hose based on acrylic epoxy resin during transportation. The rubber hose includes a double-tube packaging tube 1 and a sealing cover 6, and the top of the double-tube packaging tube 1 is provided with an opening. 8. The opening 8 is provided with a sealing cover 6, and a partition 9 is fixedly installed at the inner bottom of the double-barrel packaging tube 1, and the partition 9 extends from the bottom of the double-barrel packaging tube 1 to the opening 8, and the The double-barrel packaging tube 1 is divided into a first rubber tube 3 and a second rubber tube 2 which are independent of each other. The inner bottom of the first rubber tube 3 is provided with a first rear cover 4, and the inner bottom of the second rubber tube 2 is provided with a second rear cover. Cover 5, the inside of the first rubber tube 3 is filled with a mixture of acrylic epoxy resin, inor...

Embodiment 2

[0034] Basically the same as Example 1, the difference is that the acrylic epoxy resin, inorganic material, and accelerator mixture are mixed in the following parts by weight: acrylic epoxy resin, inorganic material, and accelerator mixture are mixed in the following parts by weight: acrylic acid ring 35 parts of oxygen resin, 75 parts of inorganic material, and 1 part of accelerator. The accelerator is methylaniline.

Embodiment 3

[0036] Basically the same as Example 1, the difference is that the acrylic epoxy resin, inorganic material, and accelerator mixture are mixed in the following parts by weight: acrylic epoxy resin, inorganic material, and accelerator mixture are mixed in the following parts by weight: acrylic acid ring 30 parts of oxygen resin, 70 parts of inorganic material, and 0.8 parts of accelerator.

[0037] The planting bar glue performance test result of above-mentioned embodiment is as table 1:

[0038] Table 1 carries out performance test for the planting bar glue of embodiment 1,2,3

[0039] Example serial number

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap