Magnetic suspension vibration isolation platform

A vibration isolation platform and magnetic levitation technology, applied in non-rotation vibration suppression and other directions, can solve the problems of no fixed frequency and active vibration isolation, and achieve the effect of good vibration isolation effect, simple structure and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

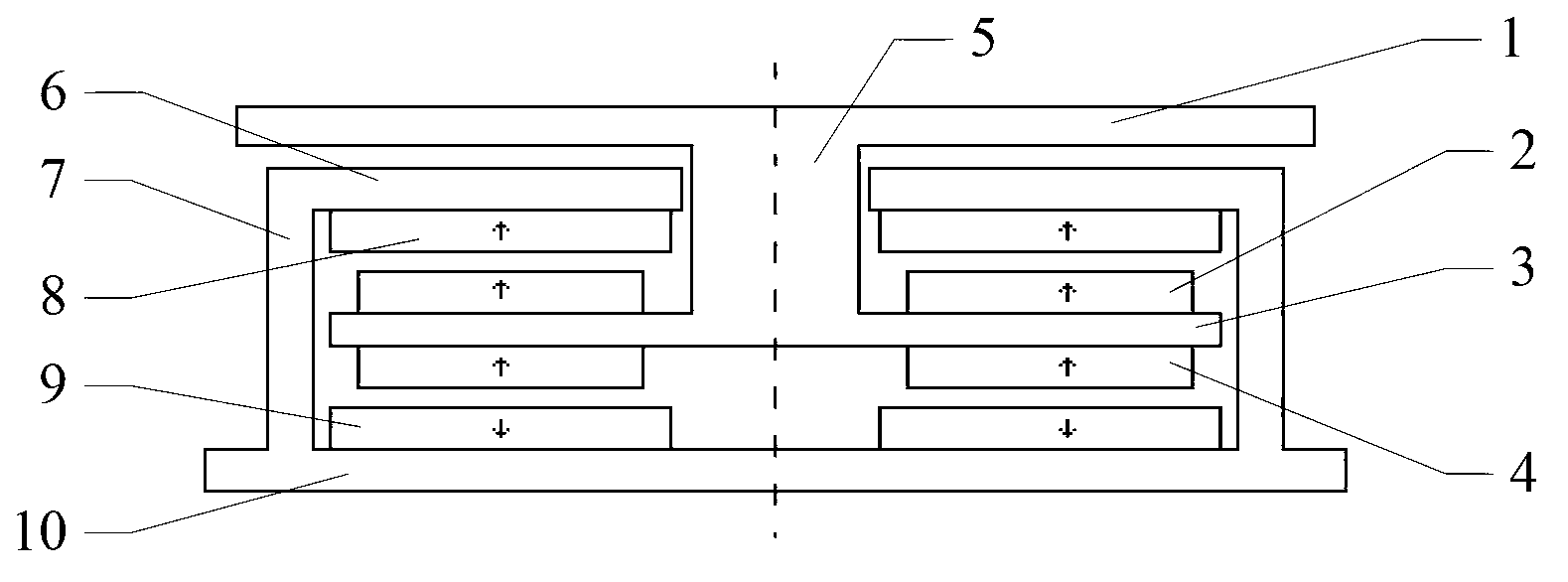

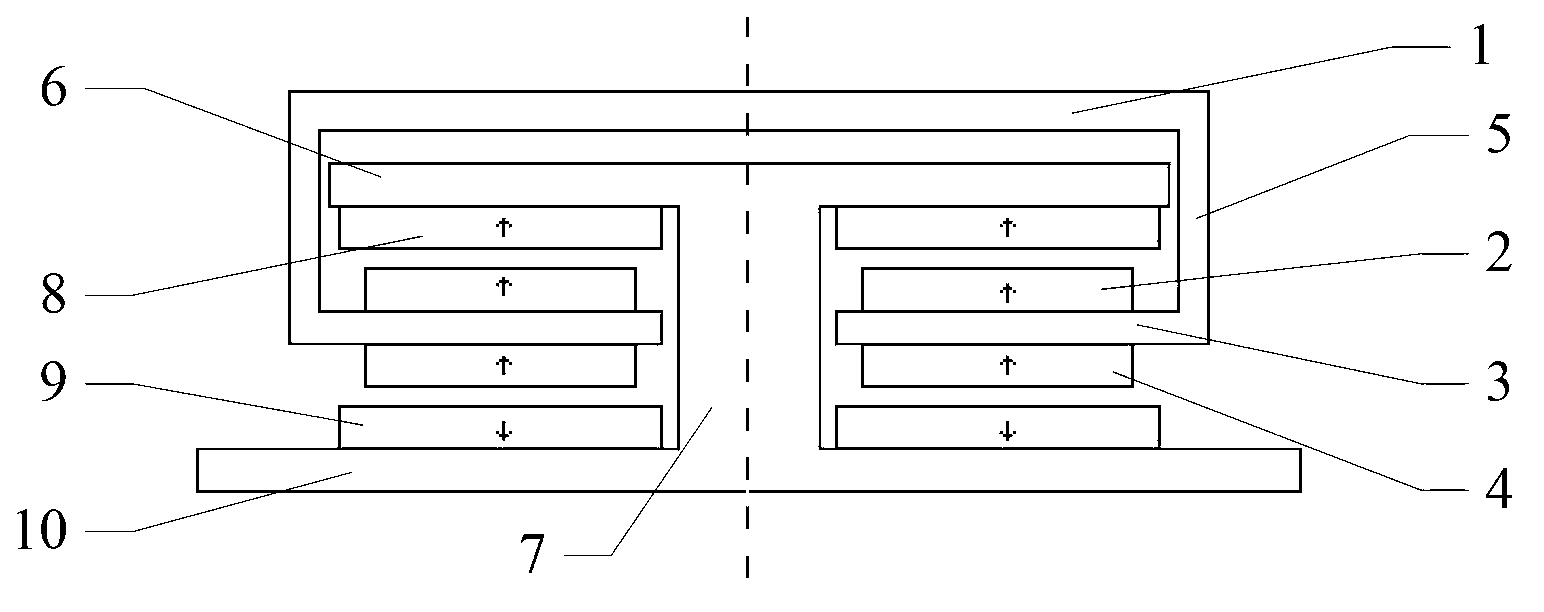

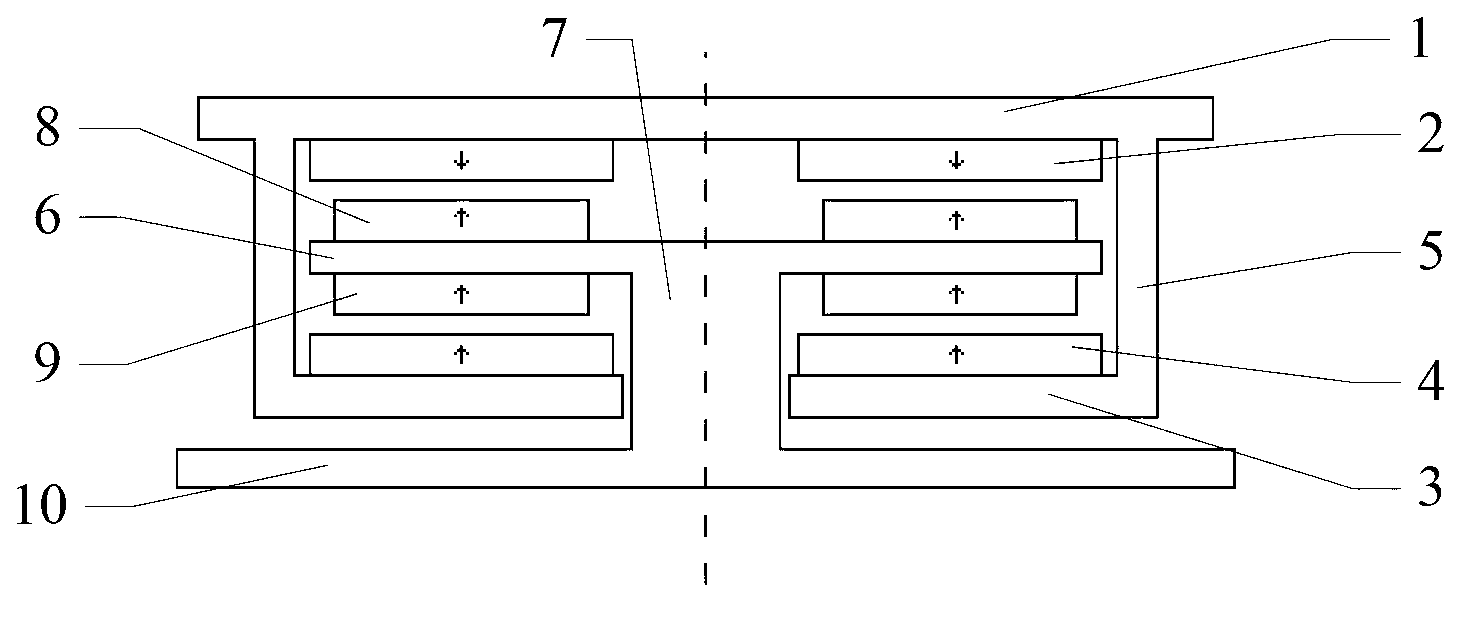

[0056] Specific Embodiments 1. The magnetic suspension vibration isolation platform described in this embodiment is composed of a moving base plate, a fixed base plate, n static load-bearing units, i Z-direction adjustment units, j X-direction adjustment units, and j Y-direction adjustment units. n and i are natural numbers greater than or equal to 3, and j is a natural number greater than or equal to 2; the static load-bearing unit, Z-direction adjustment unit, X-direction adjustment unit and Y-direction adjustment unit are symmetrically arranged on the moving base plate and the fixed axis along the X-direction or Y-direction Between the substrates; the Z-direction adjustment unit is mainly composed of a Z-direction actuator, a Z-direction unit controller and a Z-direction sensor, and the X-direction adjustment unit is mainly composed of an X-direction actuator, an X-direction unit controller and an X-direction sensor. The Y-direction adjustment unit is mainly composed of a Y-...

specific Embodiment approach 2

[0062] Specific Embodiment 2. The static load-bearing unit of the magnetic suspension vibration isolation platform described in this embodiment includes a static load-bearing unit mover and a static load-bearing unit stator, and the static load-bearing unit mover includes a first excitation component, a load-bearing platform 1 and a load-bearing support frame, the first excitation component is fixed below the load-bearing platform through the load-bearing support frame, and the permanent magnet in the first excitation component is magnetized in parallel in the vertical direction;

[0063] The static load-bearing unit stator includes a second excitation component, a support base 10 and a support frame, the second excitation component is fixed above the support base through the support frame, and the permanent magnets in the second excitation component are magnetized in parallel in the vertical direction;

[0064] The first excitation part and the second excitation part correspon...

specific Embodiment approach 3

[0066] Specific implementation mode three, see figure 1 This embodiment will be described. This embodiment is a further limitation on the structure of the first excitation component and the second excitation component used in the magnetic suspension vibration isolation platform described in the first embodiment. In this embodiment, the first excitation component includes a first excitation The permanent magnet 2 on the part and the permanent magnet 4 under the first excitation part, the load-bearing support frame is composed of the permanent magnet fixing plate 3 of the first excitation part and the load-bearing support column 5, the permanent magnet 4 under the first excitation part and the first excitation part The upper permanent magnets 2 have the same shape and are all ring-shaped. The upper permanent magnet 2 of the first excitation part and the lower permanent magnet 4 of the first excitation part are symmetrically pasted and fixed on the upper surface and the lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com