Heat dissipation lamp housing and manufacturing method thereof, and lamp structure

A technology for heat dissipation lamps and lamps, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as high production costs, hindering heat conduction, complicated and labor-intensive manufacturing processes, and achieve Solve the effects of poor heat resistance, streamlined production process, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

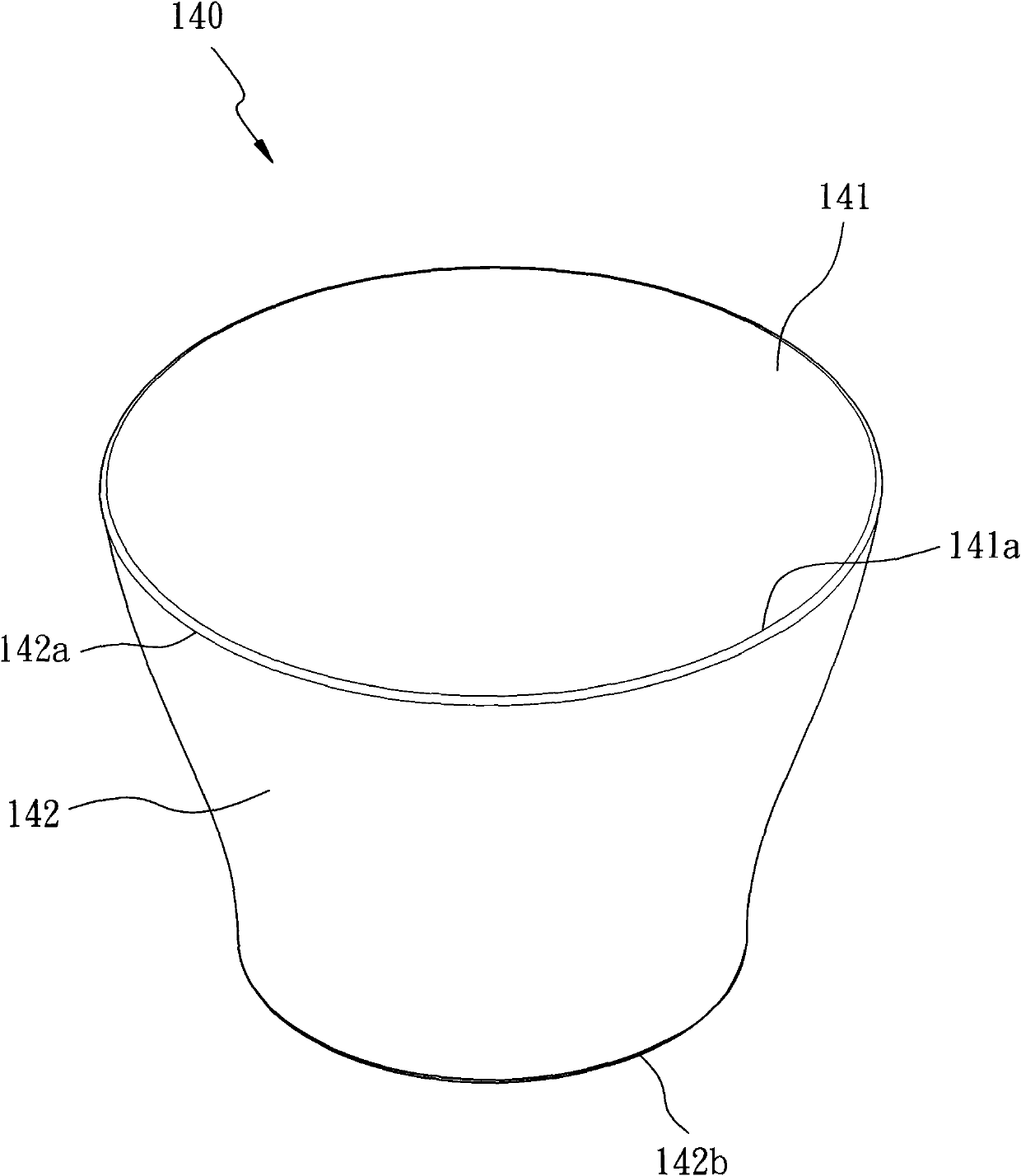

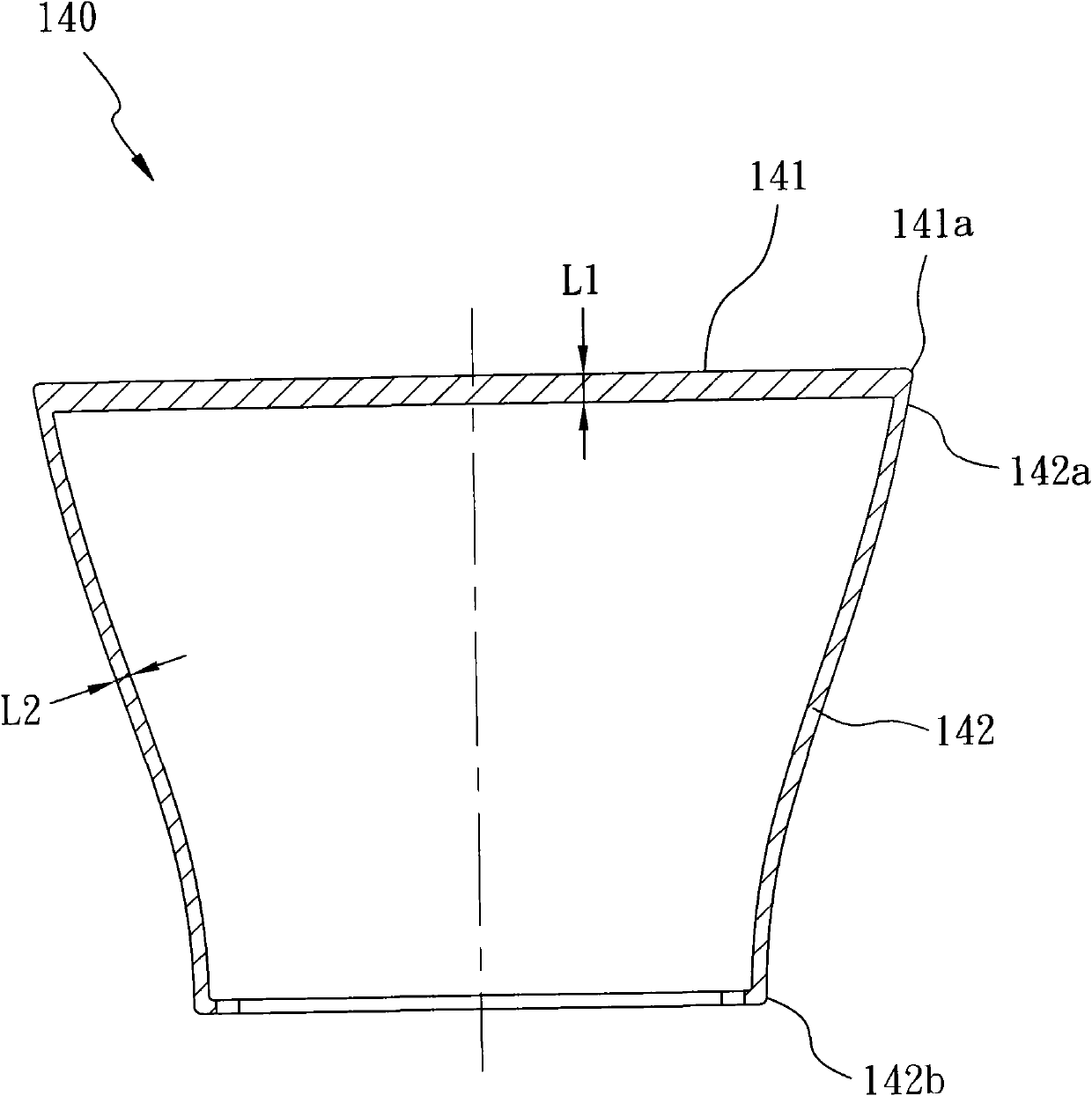

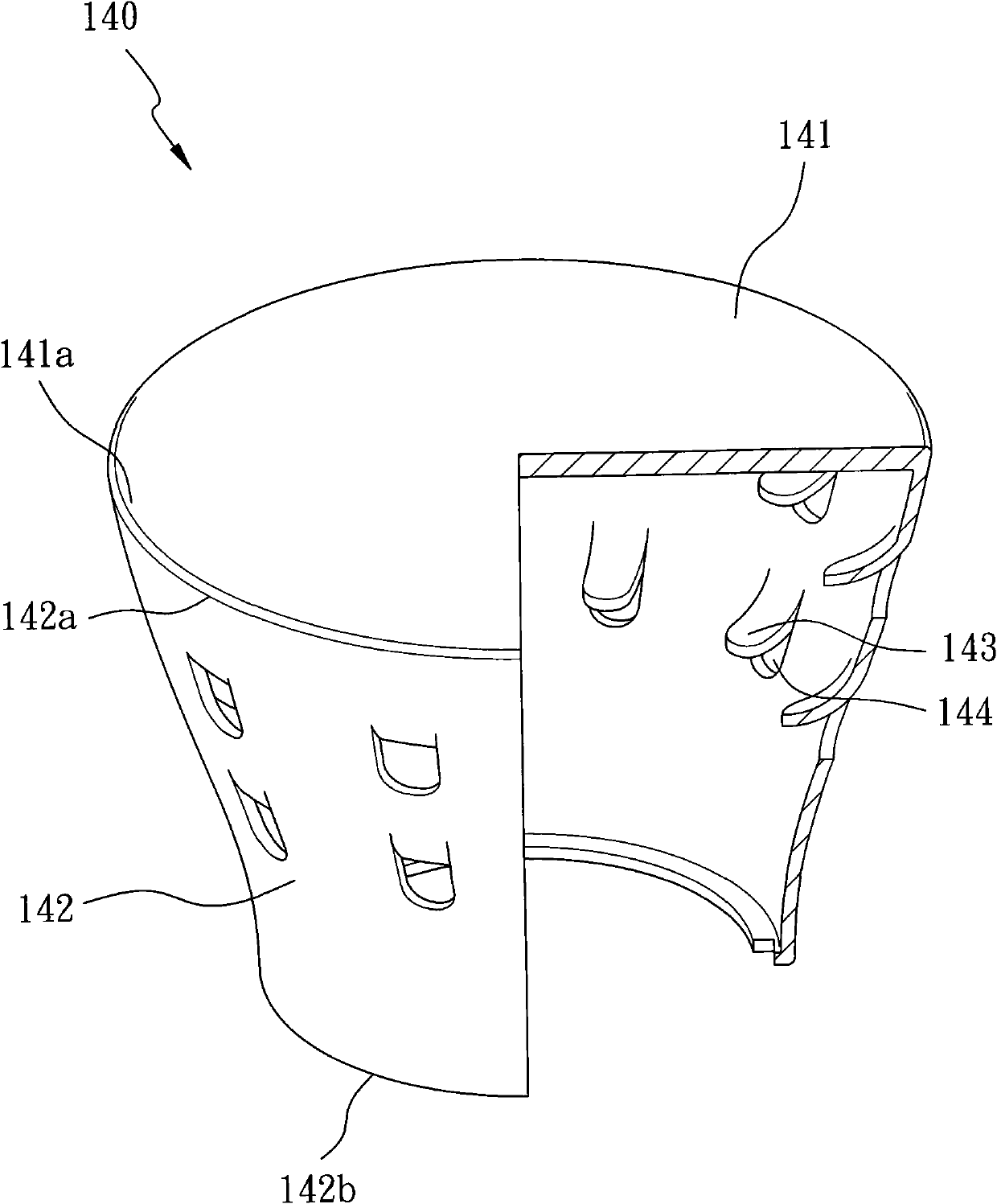

[0039] Please refer to Figure 1A and Figure 1B , Figure 1A It is a perspective view showing the heat dissipation lamp housing 140 according to the first embodiment of the first embodiment of the present invention. Figure 1B is to draw Figure 1Asectional schematic diagram. The heat dissipation lamp housing 140 is integrally formed by an extension method, and includes a conduction portion 141 and a cylinder wall 142 . The conduction part 141 has a peripheral edge 141a, and the conduction part is used to carry the light source assembly of the lamp, so that the heat energy generated by the light source assembly first flows to the conduction part 141, then flows from the conduction part 141 to the cylinder wall 142, and finally flows from the surface of the cylinder wall 142 to the Air. The cylinder wall 142 has a first end 142a and a second end 142b. The first end 142a surrounds the periphery 141a of the conduction part 141 and is completely connected with it. It has excel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com