Comprehensive processing recycling process and device of bromine-contained high temperature flue gas

A high-temperature flue gas, comprehensive treatment technology, applied in the direction of steam condensation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing kinetic energy and auxiliary nitrogen consumption, achieve environmental benefits, economic benefits are unified, and avoid secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

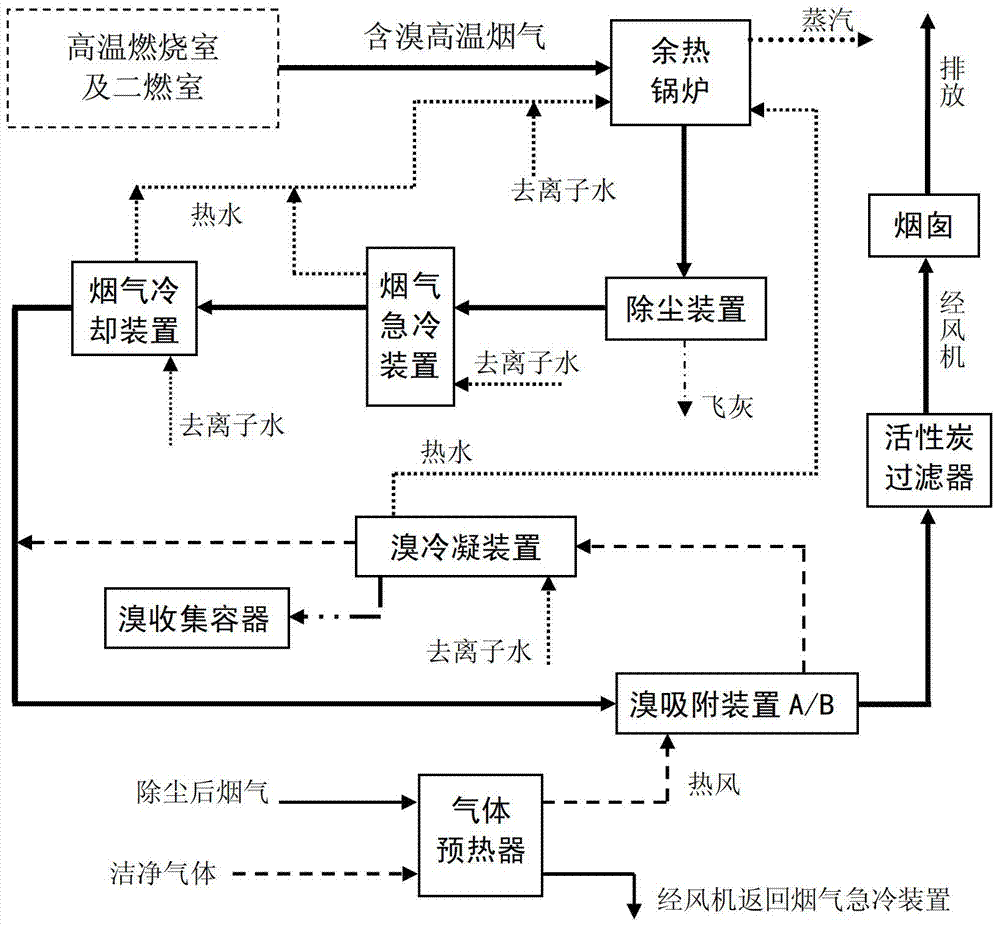

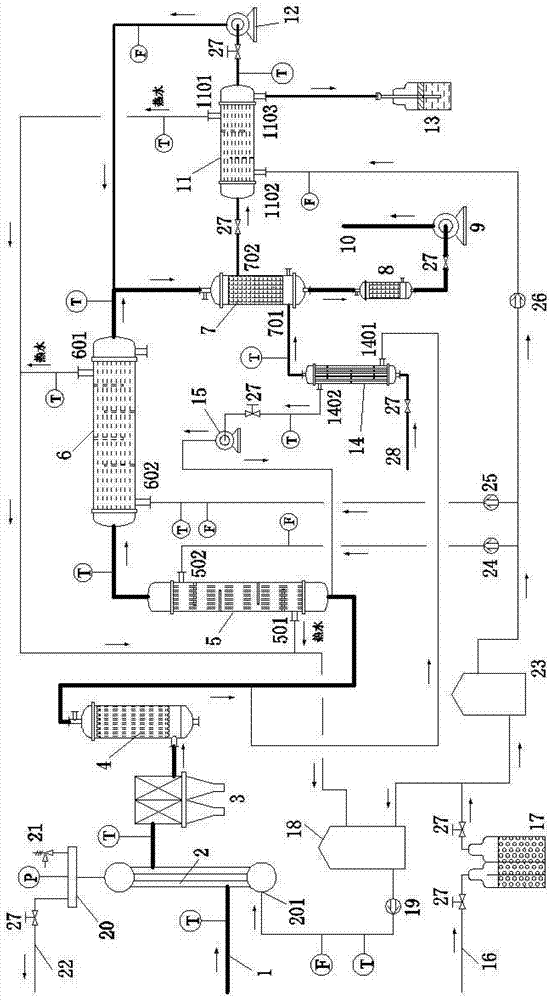

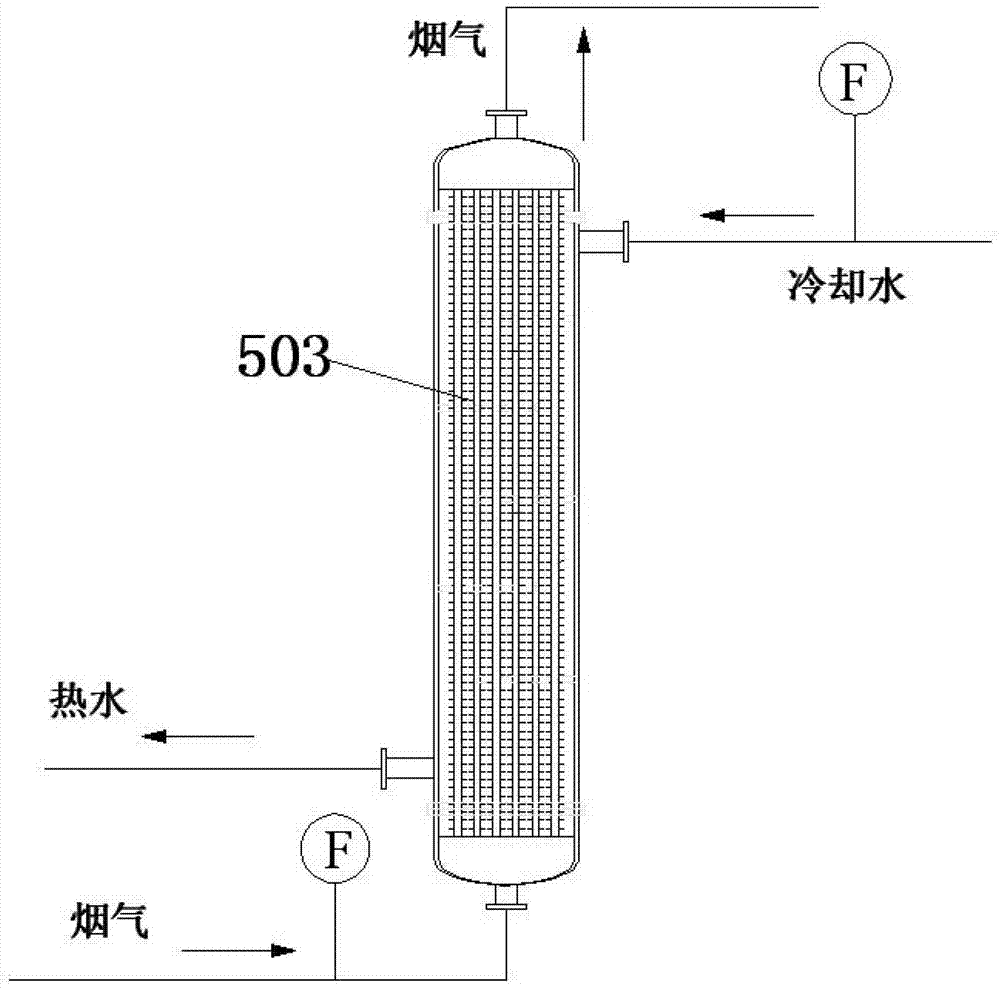

[0042] see figure 2 , the device of the present invention includes a waste heat boiler 2 connected to the exhaust pipe 1 of the high-temperature combustion chamber and the second combustion chamber. 4 is connected to the flue gas quenching device 5, the exhaust pipe of the flue gas quenching device 5 is connected to the flue gas cooling device 6, and the exhaust pipe of the flue gas cooling device 6 is connected with the bromine adsorption device 7, the activated carbon filter 8 and the chimney 10 in sequence Connect; at the same time, another inlet of the bromine adsorption device 7, that is, the hot blast inlet 701, is connected with the air outlet of the gas preheater 14, and another outlet of the bromine adsorption device 7, that is, the hot blast outlet 702, is connected with the bromine condensation device 11. The bromine condensing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com