A monocular stereo vision measurement method

A stereoscopic vision measurement and single-purpose technology, applied in the field of visual measurement, can solve the problems of low calibration accuracy, difficulty in improving accuracy, and low calibration accuracy, and achieve the effects of easy system establishment, improved measurement accuracy, and simplified matching algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

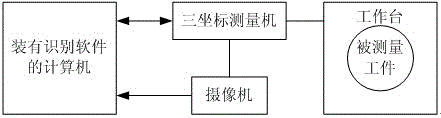

[0011] The system includes a coordinate measuring machine, a camera, a computer equipped with recognition software and the workpiece to be measured. Among them, the three-coordinate measuring machine is the main movement equipment. The camera is fixedly connected to the end of the working part of the three-coordinate measuring machine. The cable of the camera is connected with the computer equipped with the recognition software. On one side of the machine, the workpiece to be measured is placed on the measuring position on the worktable of the three-dimensional coordinate measuring machine.

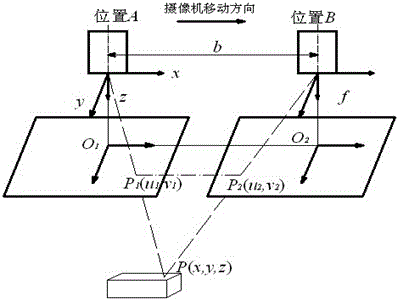

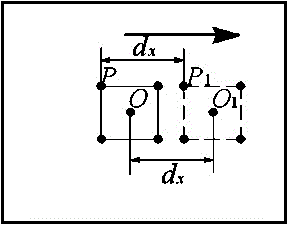

[0012] The realization of the three-dimensional coordinate monocular stereo vision measurement of feature points based on the translation of the three-coordinate measuring machine mainly includes three parts: feature point (measured point) imaging, feature point image point extraction, and feature point matching in two images with the same name. .

[0013] Place the workpiece to be measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com