Absolute detection method for surface shape error of spherical surface

A surface error and absolute detection technology, which is applied to measuring devices, instruments, optical devices, etc., can solve the problem that the surface error of the reference surface cannot be accurately separated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

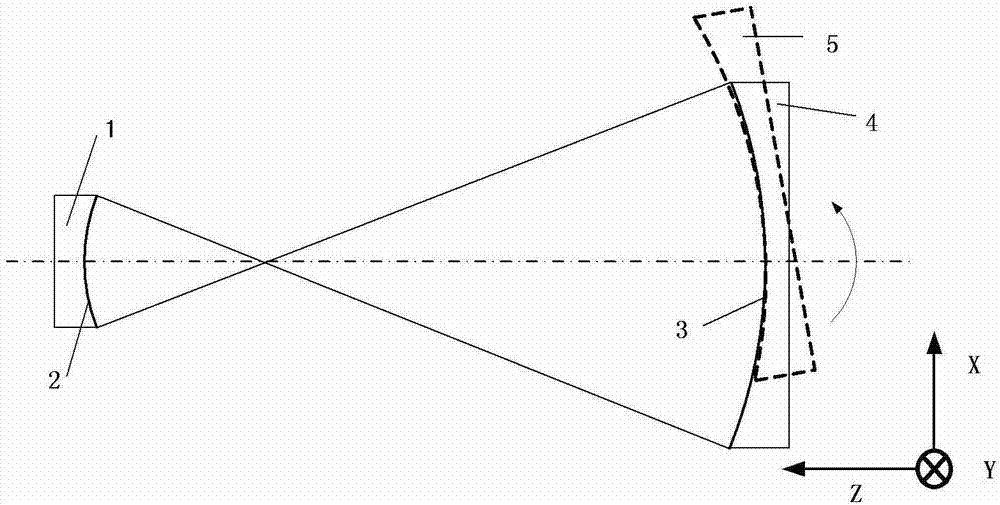

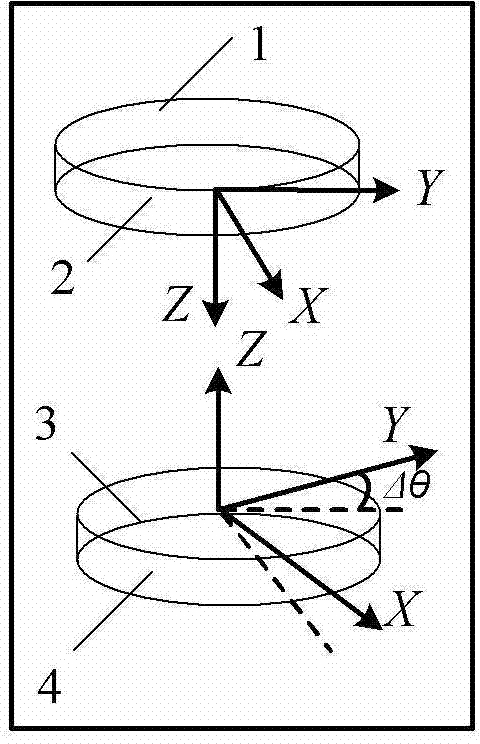

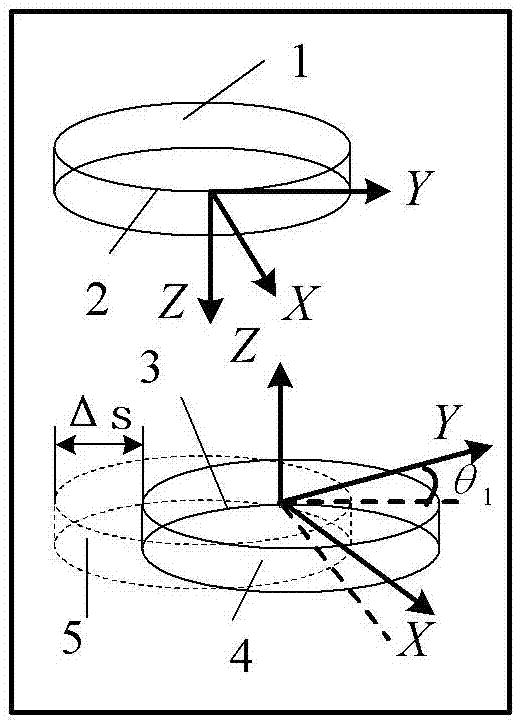

[0047] Such as figure 1 It shows the horizontal detection device when the spherical surface to be tested is a concave mirror in the present invention, which includes: a standard mirror 1, a reference surface 2, a spherical surface to be tested 3, a mirror to be tested 4, a mirror to be tested 5 after concentric translation, standard The focal point of the mirror 1 coincides with the center of curvature of the measured spherical surface 3, and the two are in a concentric position. After rotating the measured spherical surface 3 around the optical axis of the system, its concentric position relationship with the standard mirror 1 remains unchanged, and the measured spherical surface 3 When doing concentric translation along a certain direction, the concentric position relationship between the measured spherical surface 3 and the standard mirror 1 also re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com