Pressure sensor

A pressure sensor and sleeve technology, applied in the field of sensors, can solve the problems of stability, consistency and reliability limitations, and unsuitable grain granular pressure measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

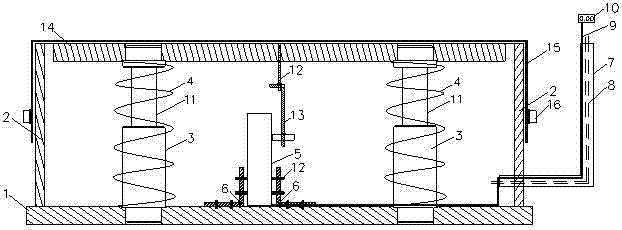

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] As shown in the accompanying drawings, the present invention is a pressure sensor suitable for granular grains, including a bottom plate 1, a side plate 2, a sleeve 3, a spring 4, a sliding resistor 5, a steel clip 6, a cast iron pipe 7, a wire 8, Air duct 9, digital voltmeter 10, pin shaft 11, screw 12, guide rod 13, top plate 14, latex sheet 15, clamp 16, the top plate 14 bears the vertical grain pressure, causing the spring 4 to deform downward, driving the guide rod 13 moves downward, causing the resistance value of the sliding resistor 5 to change, and the voltage signal to change, thereby realizing pressure sensing.

[0016] As shown in the drawings, the bottom plate 1 is welded together with three side plates 2 to form a cube with an upper surface and a side opening. The sleeve 3 and the pin shaft 11 are processed by tooling, and the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com