Manufacture method of large-scale geomechanical model

A technology of geomechanics and manufacturing methods, applied in teaching models, manufacturing tools, ceramic molding machines, etc., can solve problems such as affecting the overall mechanical parameters of the model, distortion of measurement parts, and inability to ensure the uniformity of the model body and the consistency of mechanical properties, etc. Achieve the effect of eliminating size effect, protecting from damage, and eliminating delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

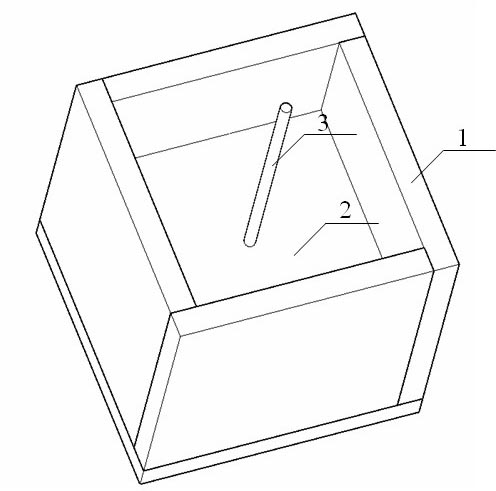

[0035] like figure 1 , 2 shown,

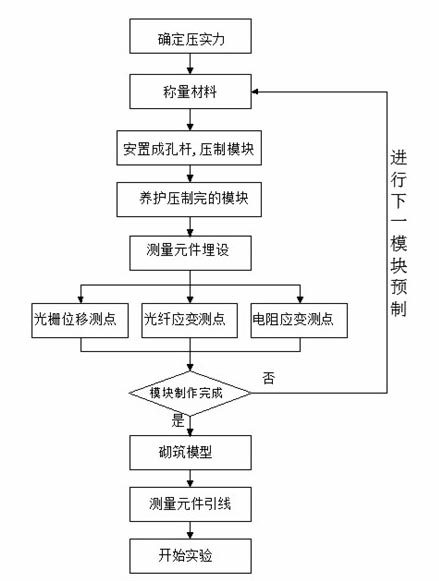

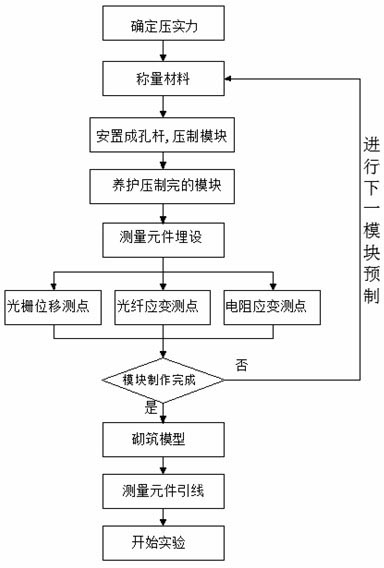

[0036] A method for making a large-scale geomechanical model, the steps are:

[0037] 1) Prepare the material according to the experimentally determined mixing ratio and lay the weighed material in the pressing mold 1. The material weight of the prefabricated module 2 is (In the formula: Design volume for the model body). In order to ensure the convenience of construction, the number of the prefabricated standard modules is 2 The determination of the weight of the prefabricated module needs to be guaranteed Not more than 20Kg. The prefabricated module is in a square shape, and its length, width and height are all about 20cm. Considering that the size of the proposed model body is generally about 1m square, the total number of prefabricated modules 2 to be pressed is About 100-200 pieces.

[0038] 2) The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com