Vertical semi-continuous light alloy ingot casting process and apparatus with cooperation of power ultrasound wave and low frequency electromagnetic wave

A synergistic, light alloy technology, applied in the field of light alloy casting, which can solve the problems of difficulty in casting large-sized ingots of light alloys, difficult to meet the deformation production, cracks and porosity, etc., and achieve a significant size effect of microstructure solidification and improve internal metallurgy. Quality and surface quality, the effect of coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1AZ31

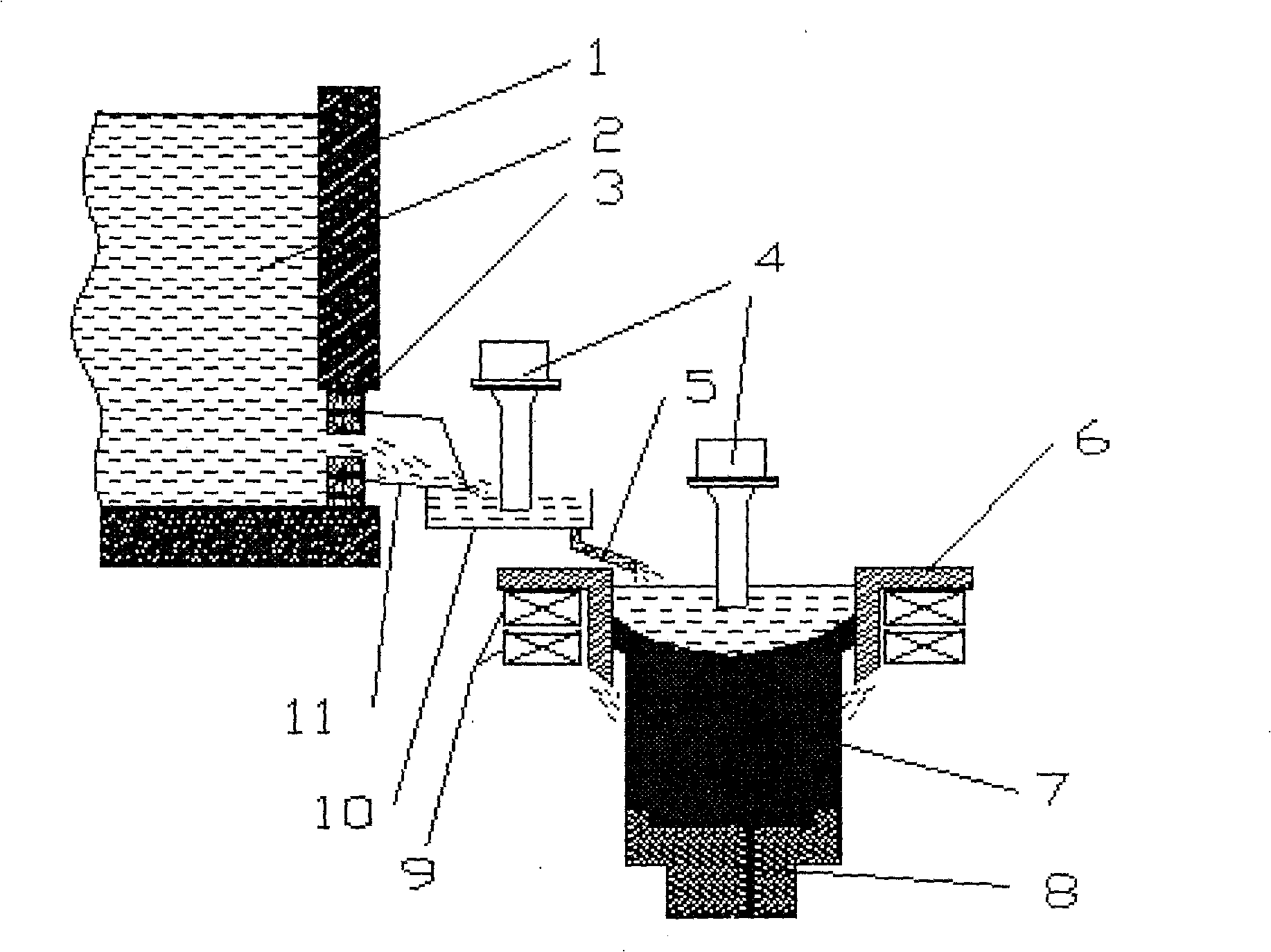

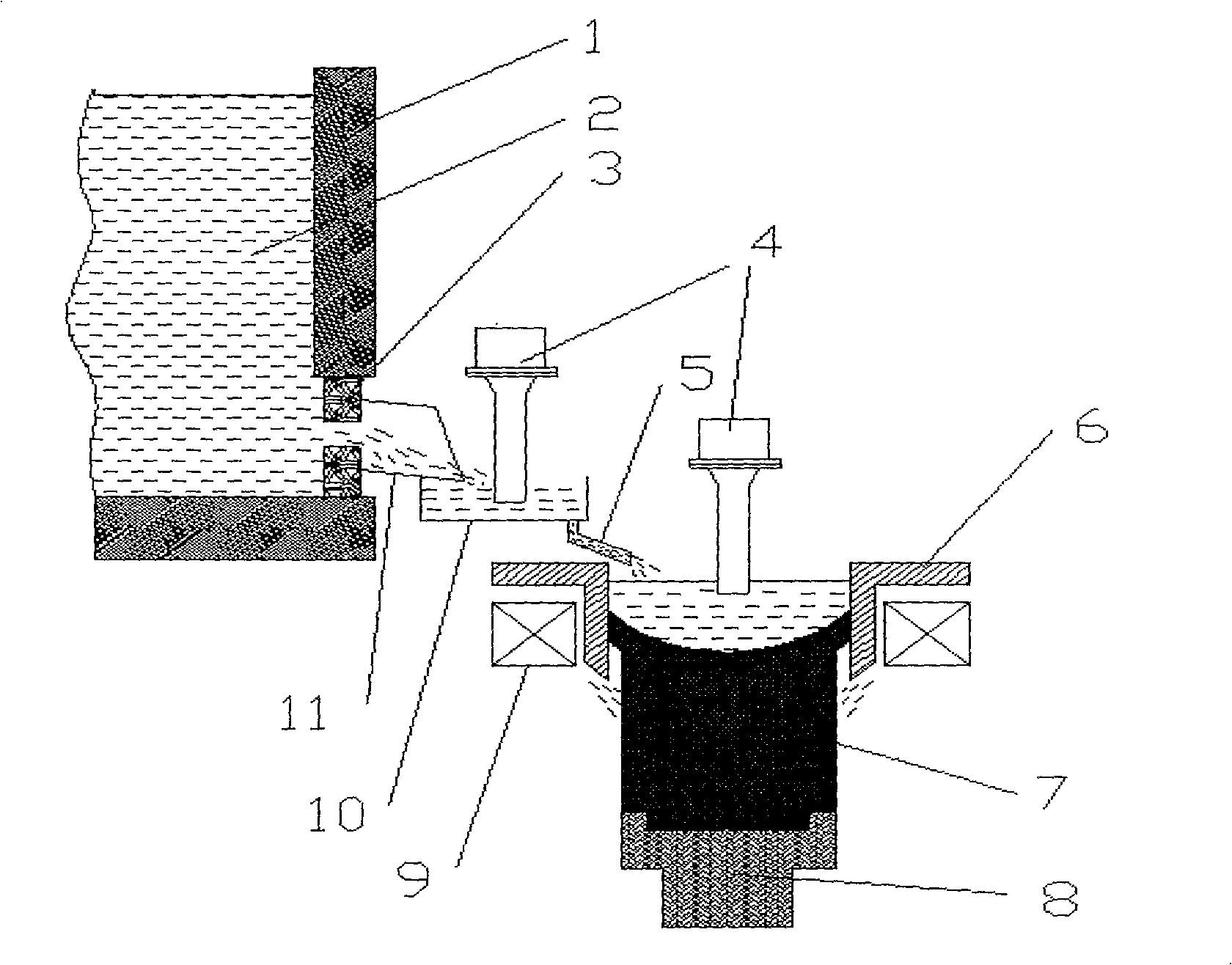

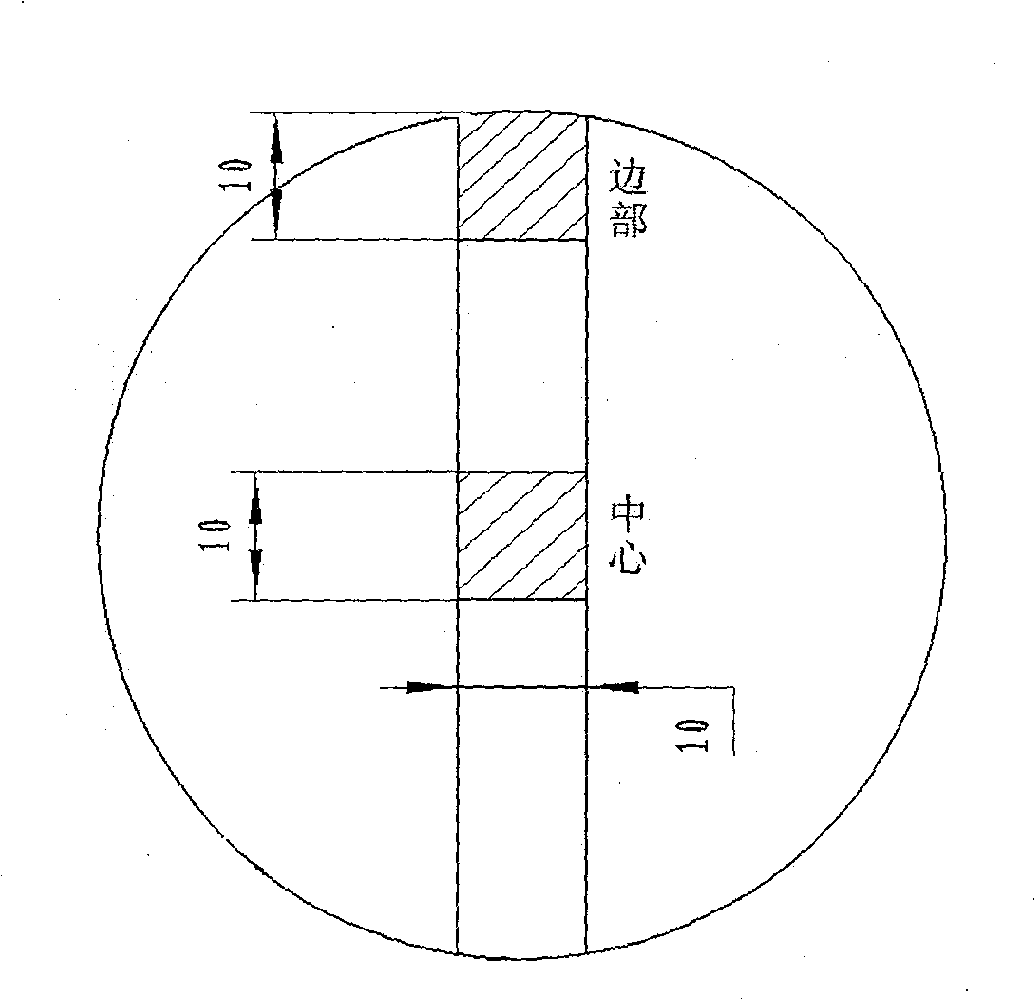

[0024] Embodiment 1 AZ31 magnesium alloy Φ200mm billet vertical semi-continuous casting

[0025] AZ31 magnesium alloy is smelted according to the ratio, and 20ppmBe is added to achieve flame retardancy; the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is not treated with ultrasonic in the tundish, and power ultrasonic is applied in the crystallizer The synergy of the field and the low-frequency electromagnetic oscillating field.

[0026] The casting process conditions are: the casting speed is 100mm / min; the Φ20mm low carbon steel ultrasonic horn is preheated at 300°C for 1 hour; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 6W / cm 2 ; The melt temperature in the tundish is 690°C; the AC frequency is 30Hz, the intensity is 4000AT; the DC intensity is 4000AT.

[0027] Figure 4 The microstructure comparison of AZ31 magnesium alloy Φ200mm ingot obtained by traditional vertical semi-continuous cas...

Embodiment 2

[0029] Example 2: Vertical semi-continuous casting of AZ80 magnesium alloy Φ300mm billet

[0030] AZ80 magnesium alloy is smelted according to the ratio, and 10ppmBe is added to achieve flame retardancy; the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is not treated with ultrasonic in the tundish, and power ultrasonic is applied in the crystallizer The synergy of the field and the low frequency electromagnetic field.

[0031] The casting process conditions are: the casting speed is 90mm / min; the Φ20mm low carbon steel ultrasonic horn is preheated at 300°C for 1 hour; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 5W / cm 2 ; The melt temperature in the tundish is 670°C; the AC frequency is 30Hz, and the intensity is 6000AT.

[0032] Figure 5 Microstructure comparison of AZ80 magnesium alloy Φ300mm ingot obtained by traditional semi-continuous casting, low-frequency electromagnetic vertical semi...

Embodiment 3

[0034] Example 3: Vertical semi-continuous casting of MA2-1 magnesium alloy Φ300mm billet

[0035] Smelt MA2-1 (Russian grade, equivalent to AZ41) magnesium alloy according to the ratio, and add 20ppm Be to achieve flame retardancy; the inner sleeve of the crystallizer is a hot-top metal mold inlaid with graphite rings and heat preservation caps; the melt is in the middle bag There is no ultrasonic pretreatment, and a synergistic field of power ultrasonic and low-frequency electromagnetic is applied in the crystallizer.

[0036] The casting process conditions are: the casting speed is 100mm / min; the Φ20mm low carbon steel ultrasonic horn is preheated at 300°C for 1 hour; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 10W / cm 2 ; The melt temperature in the tundish is 680°C; the AC frequency is 25Hz, and the intensity is 6000AT.

[0037] Figure 6 Microstructure comparison of MA2-1 magnesium alloy Φ300mm ingot obtained by traditional semi-continuous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com