Device and method for detecting grinding performance of material

A technology for grinding performance and testing materials, which is applied in measuring devices, testing wear resistance, and analyzing materials, etc. It can solve problems such as insufficiently objective evaluation of test results, changes in grinding force, and oversimplified test methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

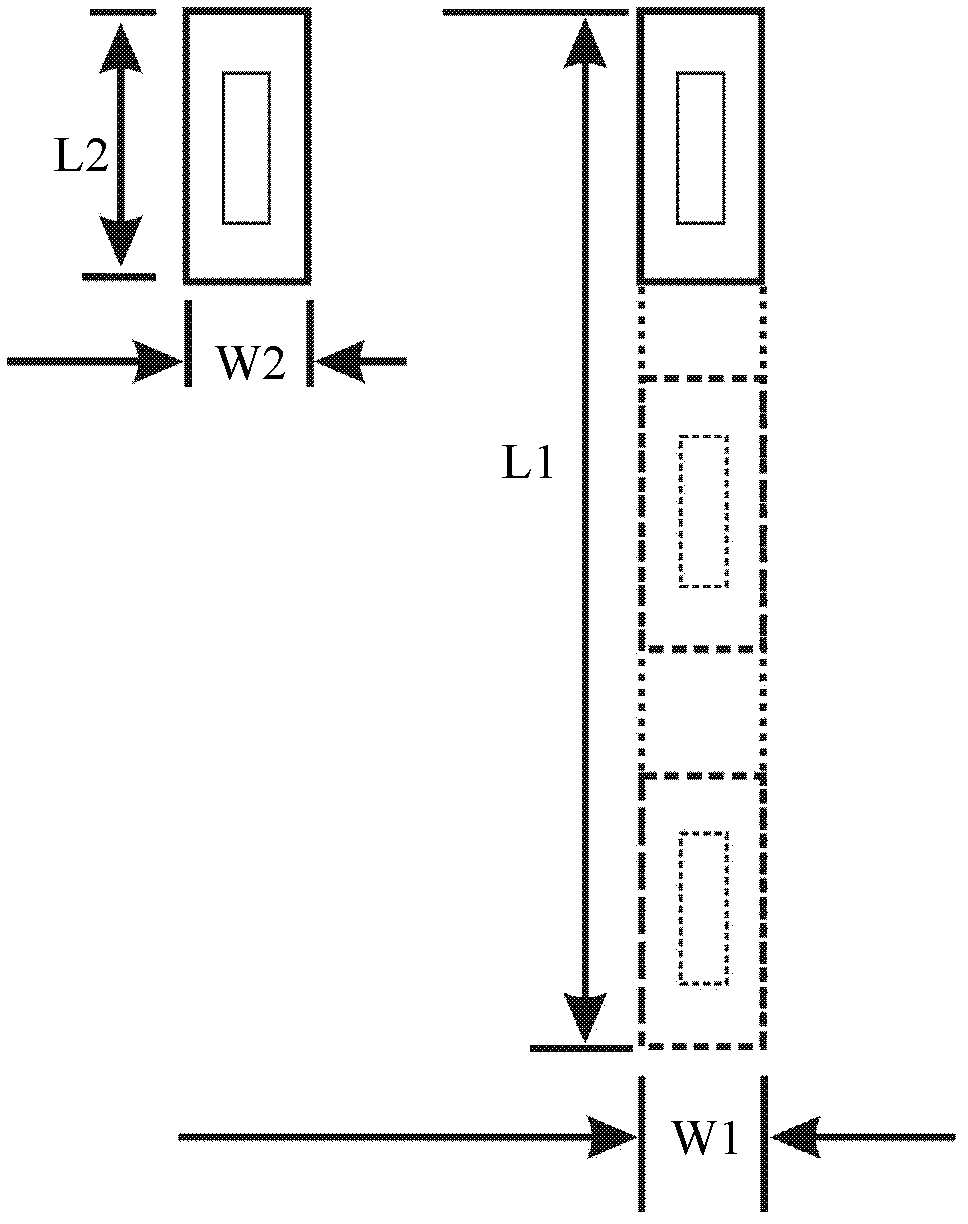

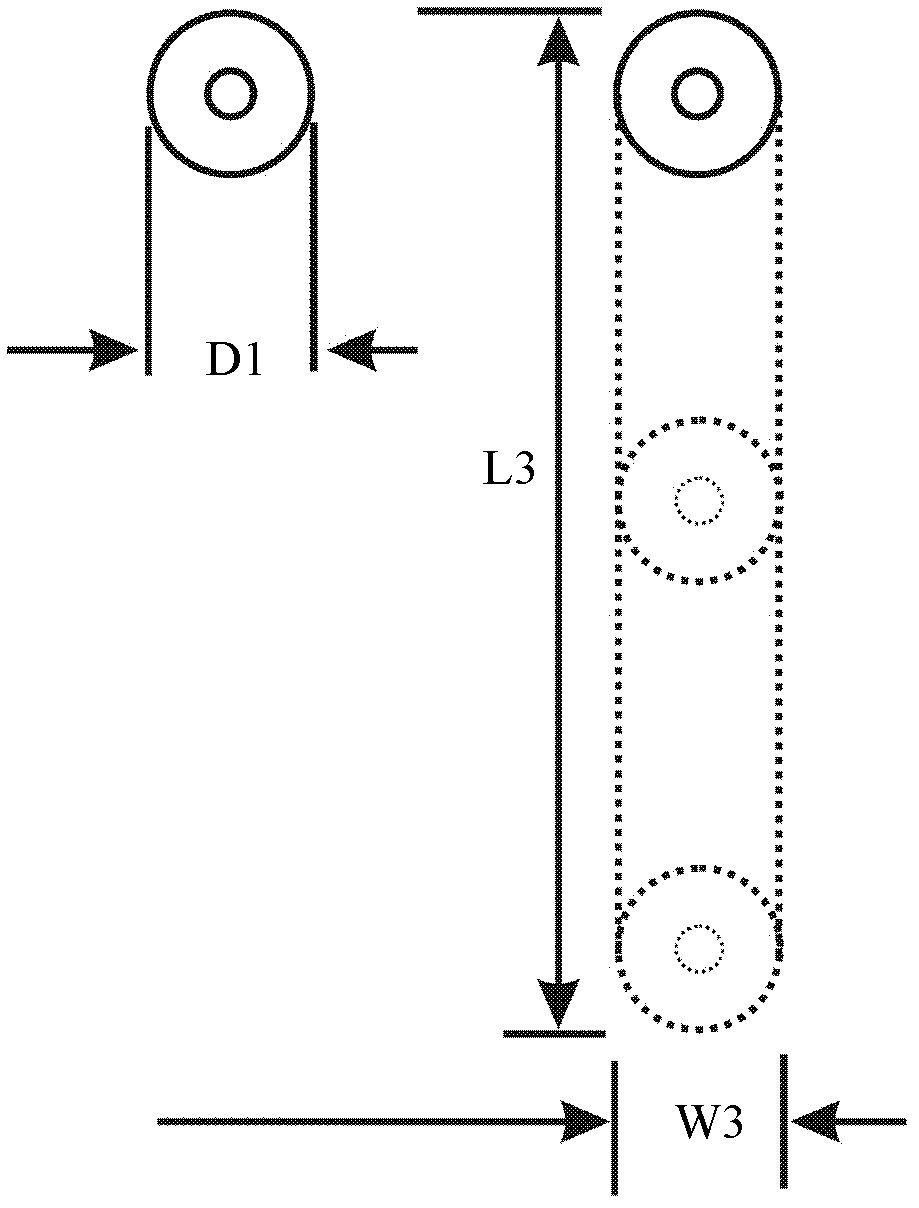

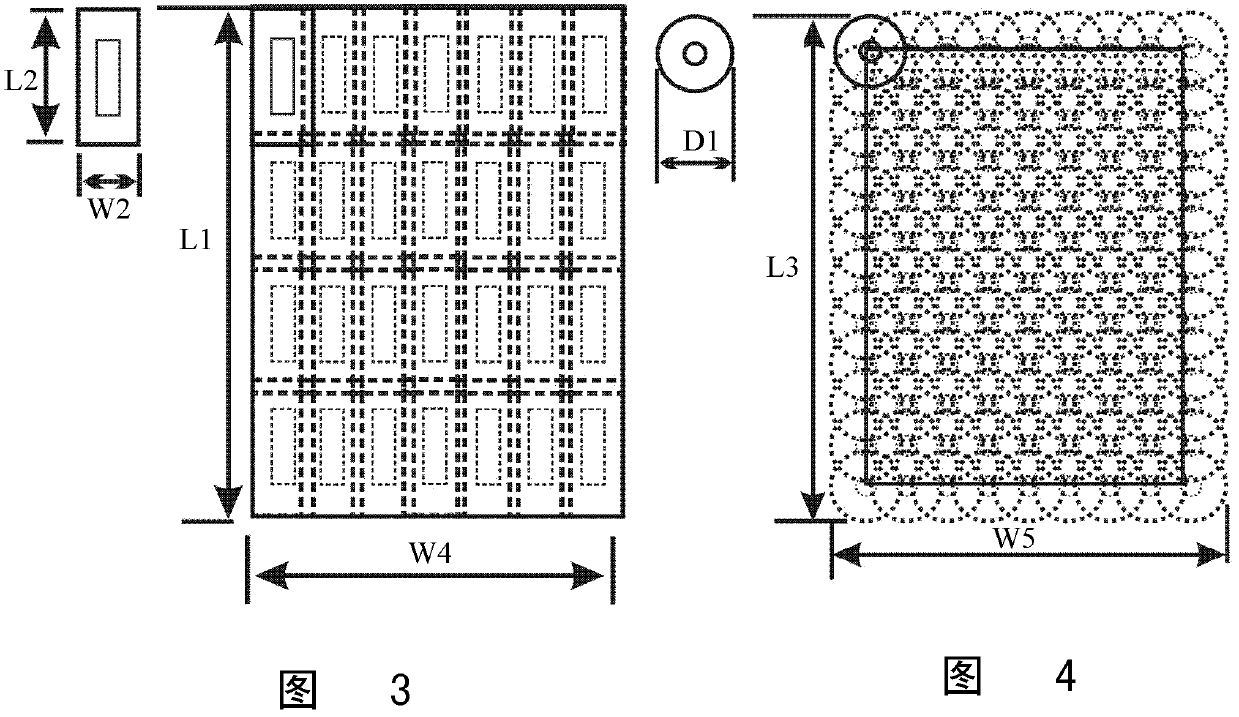

[0059] In the following embodiments, the X-axis and the Y-axis are mutually perpendicular directions in the same plane, and the Z-axis is a direction perpendicular to the plane, usually referring to a direction perpendicular to the surface of the material to be polished.

[0060] like Figure 7 and Figure 8 As shown, in one embodiment of the present invention, the device for detecting material grinding performance includes an XYZ three-dimensional adjustment device (consisting of an X-axis moving track 1, a Y-axis moving track 2, and a Z-axis displacement adjusting device 5), a position measuring instrument 8, Grinding force induction testing device 61, 62, 63, grinding material fixing device 4, polished material fixing device 3, data acquisition system 93, data processing system 92, data control system 91 (such as Figure 15 shown).

[0061] In other embodiments of the present invention, the XYZ three-dimensional adjustment device is not limited to Figure 7 , 8 In the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com