Blue phase liquid crystal display device capable of achieving visual angle controllable characteristic and transflective characteristic

A blue-phase liquid crystal and display device technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of not achieving color timing display, and achieve the effect of reducing driving difficulty and manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

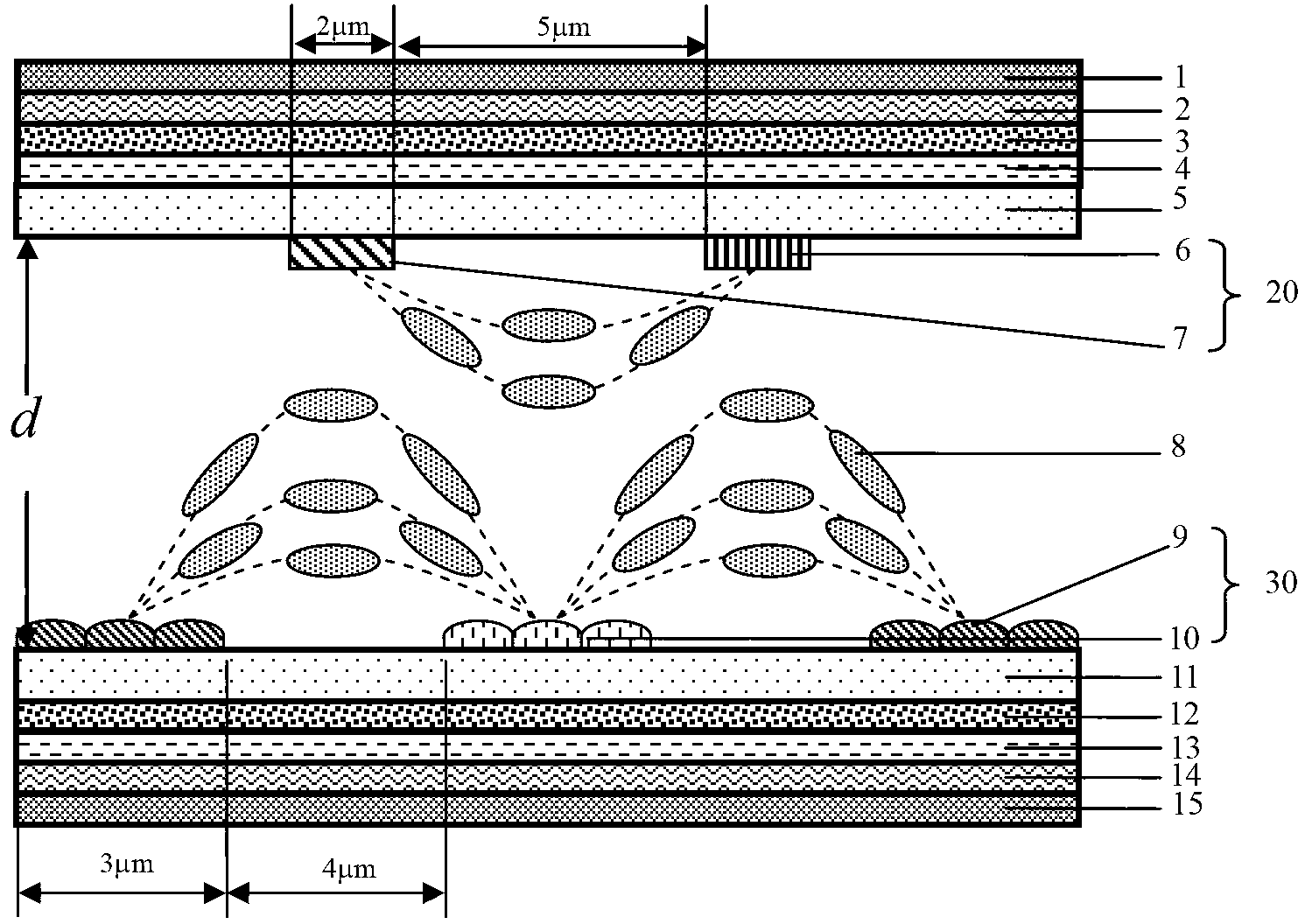

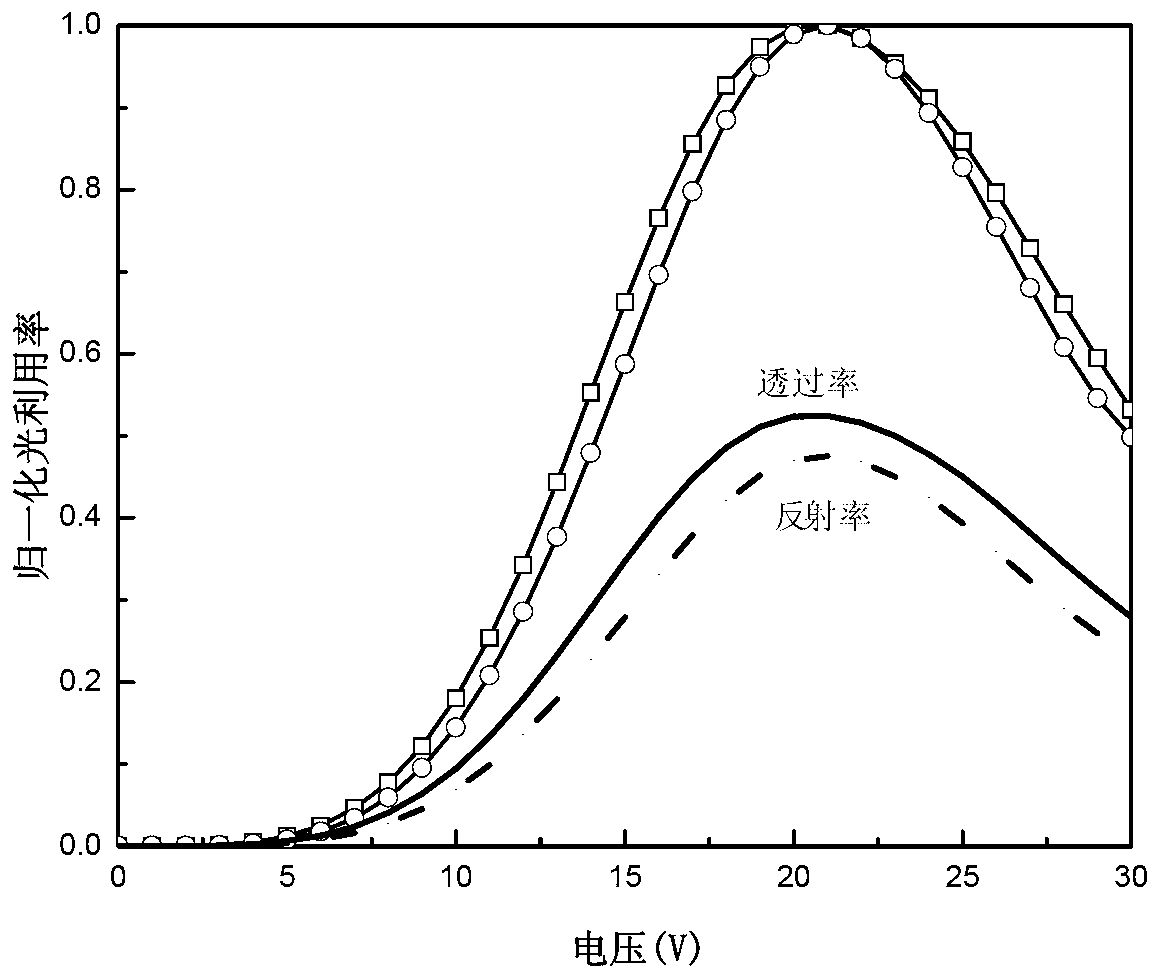

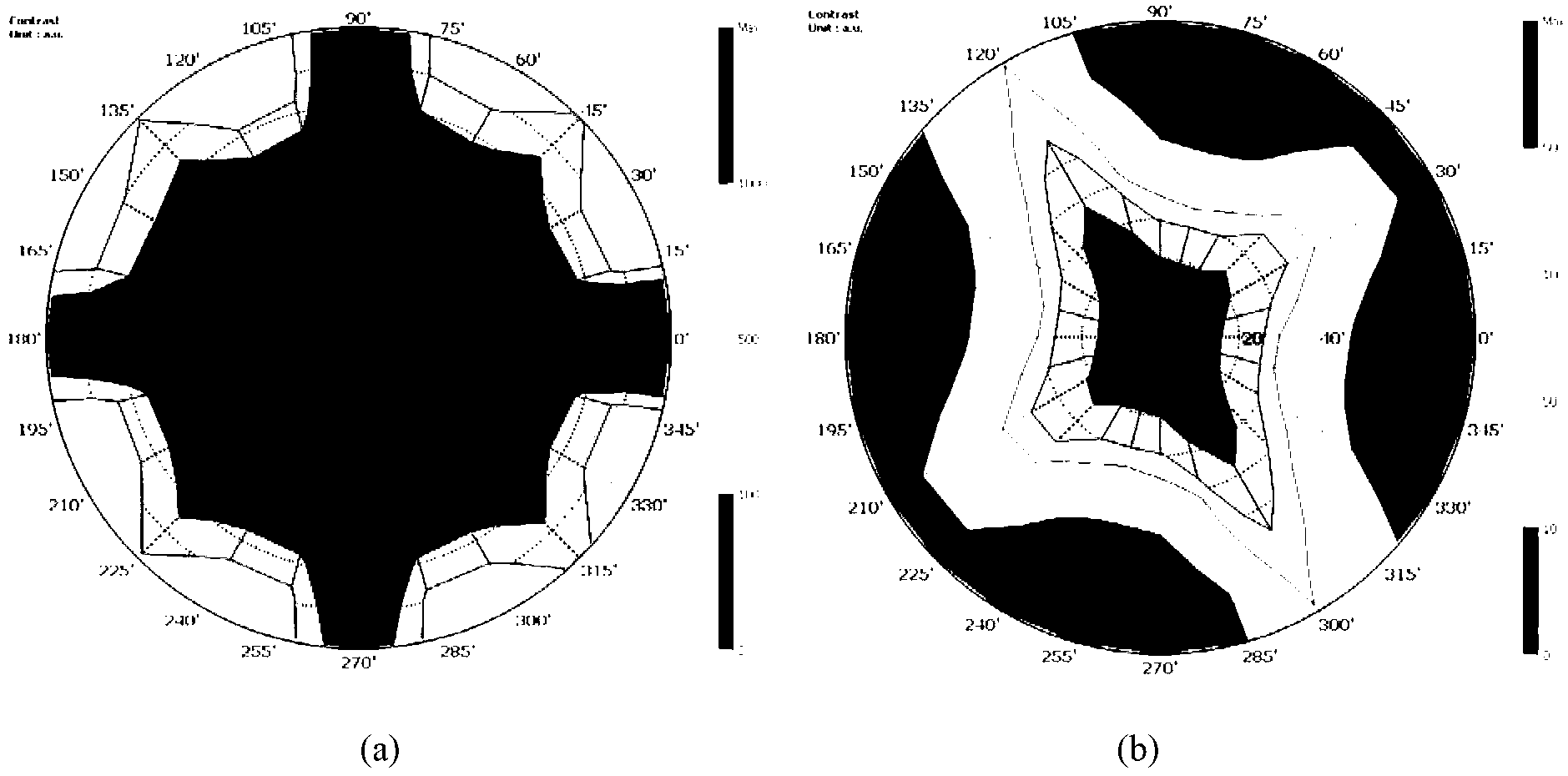

Embodiment 1

[0031] figure 1 It is a schematic structural diagram of a blue-phase liquid crystal display device that can realize controllable viewing angle and transflective display according to the patent of the present invention. The device includes from top to bottom: upper polarizer 1, upper λ / 4 biaxial film 2, upper λ / 2 Negative A plate 3, upper λ / 4 positive A plate 4, upper substrate 5, upper substrate IPS electrode 20, blue phase liquid crystal 8, lower substrate IPS electrode 30, lower substrate 11, lower λ / 4 negative A plate 12, lower λ / 2 positive A plate 13 , lower λ / 4 biaxial film 14 and lower polarizing plate 15 . Among them: the upper substrate IPS electrode 20 is an ITO electrode, located on the lower surface of the upper substrate 5, including the upper substrate Pixel electrode 6 and the upper substrate Common electrode 7, arranged at intervals; the lower substrate IPS electrode 30 is an aluminum electrode, and its position is located at intervals. Right below the gap bet...

Embodiment 2

[0053] Figure 5 It is a schematic structural diagram of a blue-phase liquid crystal display device that can realize controllable viewing angle and transflective display according to the patent of the present invention. The device includes from top to bottom: upper polarizer 1, upper λ / 4 biaxial film 2, upper λ / 2 Negative A plate 3, upper λ / 4 positive A plate 4, upper substrate 5, upper substrate IPS electrode 20, blue phase liquid crystal 8, lower substrate IPS electrode 30, lower substrate 11, lower λ / 4 negative A plate 12, lower λ / 2 positive A plate 13 , lower λ / 4 biaxial film 14 and lower polarizing plate 15 . Among them: the upper substrate IPS electrode 20 is an ITO electrode, located on the lower surface of the upper substrate 5, including the upper substrate Pixel electrode 6 and the upper substrate Common electrode 7, arranged at intervals; the lower substrate IPS electrode 30 is an aluminum electrode, located on the lower substrate 11 The surface, including the Pix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com