Array substrate and manufacturing method thereof and display panel

A technology of array substrates and substrate substrates, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as poor display, achieve enhanced display effects, improve picture display quality, and improve user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

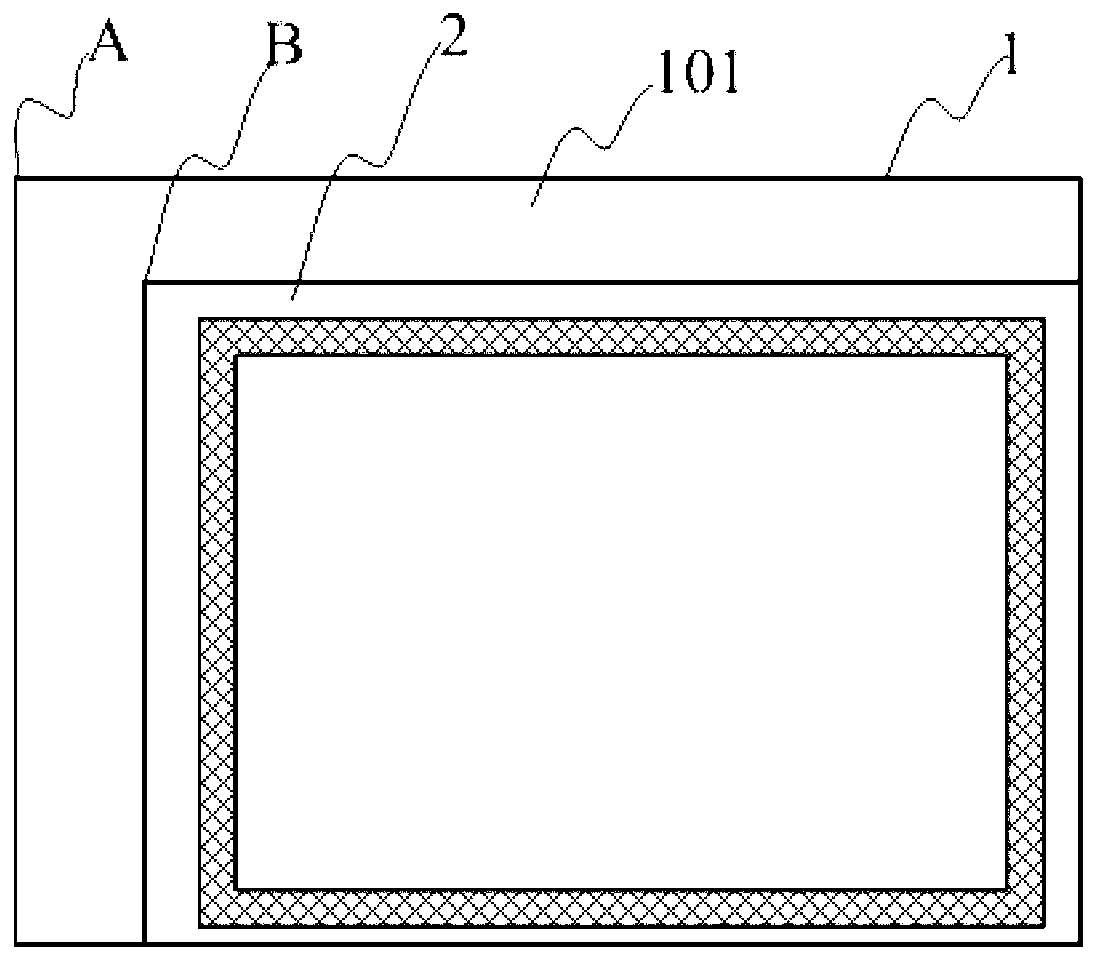

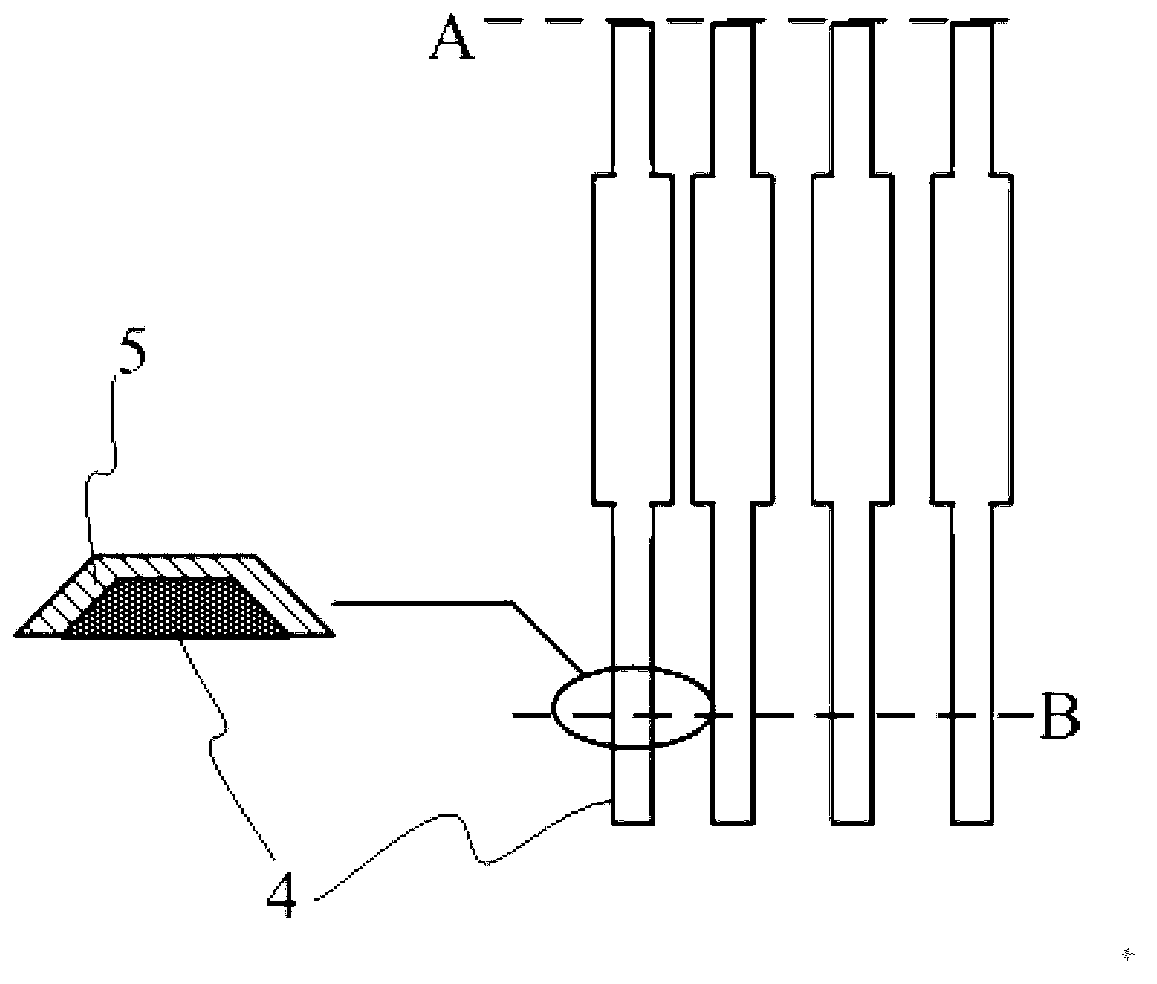

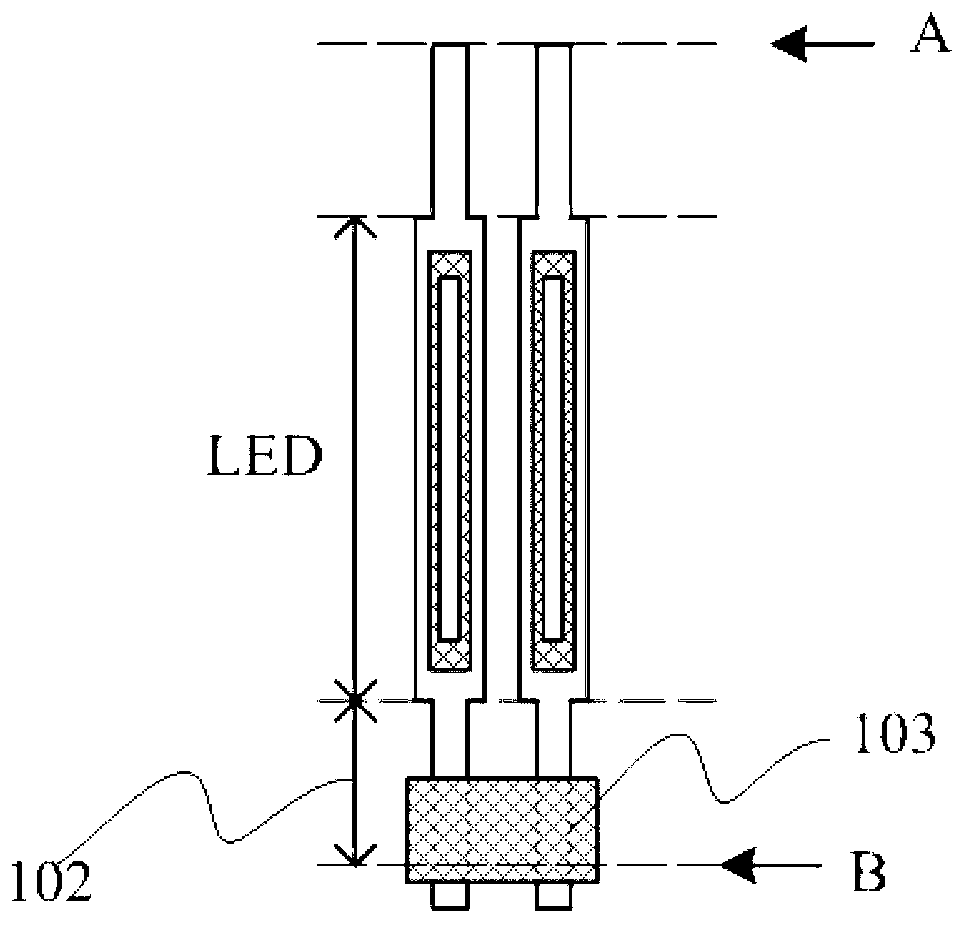

[0048] A method for preparing an array substrate provided by an embodiment of the present invention includes: forming a gate scanning line on a base substrate, forming a gate insulating layer above the gate scanning line, forming an active layer above the gate insulating layer, and forming an active layer on the active layer. Fabricate a data line above the data line, fabricate a passivation layer above the data line, and fabricate a pixel electrode on the passivation layer; the method also includes:

[0049] Make a connection line corresponding to each data line above the base substrate, and the connection line is connected to the data line through the bridge structure of the LED area and the area below the cutting line of the box substrate;

[0050] Fabricate a bridging structure above the passivation layer, and the bridging structure is arranged on the same layer as the pixel electrode.

[0051] Preferably, the method further includes: forming a first-type via hole penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com