Machining method for turning regular triangular pyramid or right-angled triangular pyramid

A technology of a regular triangular pyramid and a processing method, which is applied in the processing field of a regular triangular pyramid or a right-angled triangular pyramid, can solve the problems of high cost, inability to realize parts processing, and long working hours, etc., and achieves saving processing costs, improving work efficiency, and processing operations. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

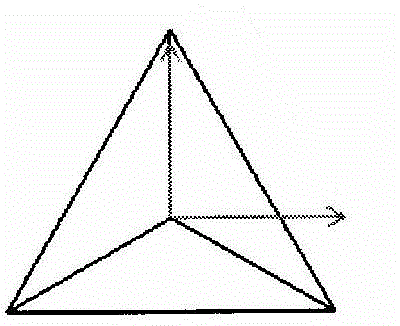

[0028] like figure 1 Shown regular triangular pyramid, its processing method comprises the following concrete steps:

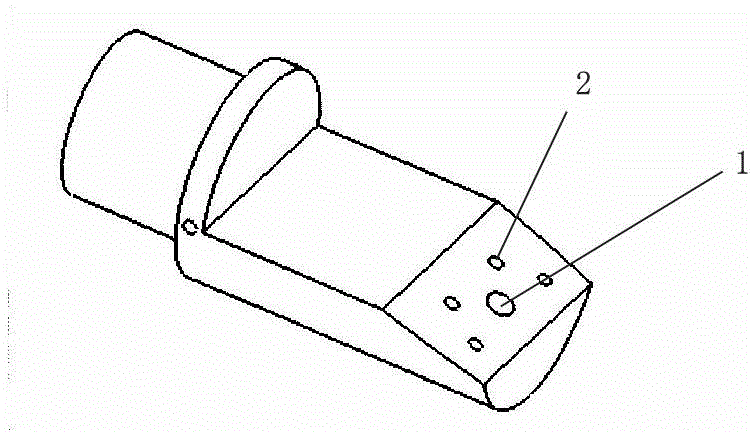

[0029] (1) Make the auxiliary fixture: design the clamping hole 1 and the inclination angle of the auxiliary fixture according to the key properties of the regular triangular pyramid, and the inclination angle is 160.53°, such as image 3 shown;

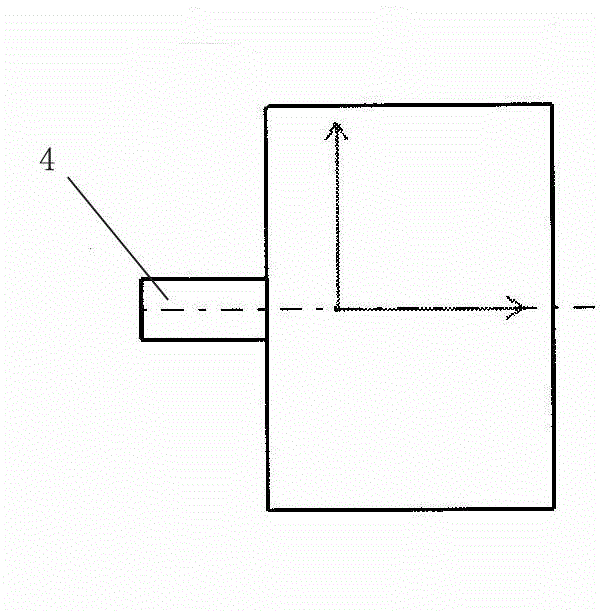

[0030] (2) Processing step 1: blanking, processing the blank into a bar, and processing the process chuck 4 with an ordinary lathe, such as figure 2 shown;

[0031] (3) Processing step 2: Put the workpiece with the process chuck 4 on the auxiliary fixture, make the workpiece’s process chuck 4 fall into the clamping hole 1 and use the pressure plate 3 to position the workpiece firmly, and then clamp the auxiliary fixture and the workpiece The first plane of the workpiece is machined on an ordinary lathe, and the right end face of the auxiliary fixture is used as the basis for cutting positioning during processing,...

Embodiment 2

[0038] like Figure 7 Shown right-angled triangular pyramid, its processing method comprises the following concrete steps:

[0039] (1) Make the auxiliary fixture: Design the clamping hole 1 and the inclination angle of the auxiliary fixture according to the key properties of the right-angled triangular pyramid, and the inclination angle is 144.74°, such as Figure 9 shown;

[0040] (2) Processing step 1: blanking, processing the blank into a bar, and processing the process chuck 4 with an ordinary lathe, such as Figure 8 shown;

[0041] (3) Processing step 2: Put the workpiece with the process chuck 4 on the auxiliary fixture, make the workpiece’s process chuck 4 fall into the clamping hole 1 and use the pressure plate 3 to position the workpiece firmly, and then clamp the auxiliary fixture and the workpiece The first plane of the workpiece is machined on an ordinary lathe, and the right end face of the auxiliary fixture is used as the basis for cutting positioning during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com