Easily-dismountable welding composite baffle

A technology of easy disassembly and assembly of steel plates, applied in the direction of welding accessories, etc., can solve problems such as easy quality problems, consumption of plates and welding materials, and uneconomical problems, and achieve the effects of avoiding quality problems, improving efficiency, and being simple and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

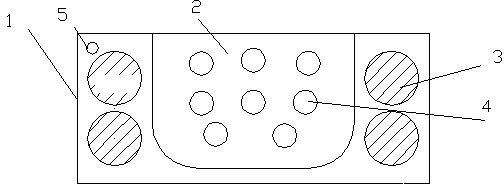

[0011] Such as figure 1 As shown, a composite baffle plate for easy disassembly and assembly welding, which includes a steel plate 1, a groove gap 2 is provided in the middle of the steel plate, and two sink holes are processed on both sides of the groove gap, and a strong magnet 3 is embedded in the sink hole , 8-10 air outlet holes 4 are evenly distributed on the bottom surface of the groove gap; the groove gap is covered with refractory mud and dried. The refractory mud needs to be coated and compacted, and its surface is flush with the edge of the steel plate or slightly lower than the edge of the steel plate.

[0012] In the composite baffle plate for easy disassembly and assembly welding, a through hole 5 through which a steel wire hangs through is drilled at one corner of the steel plate for easy storage and carrying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com