High-intensity magnetic field positioning high-pressure balancing leaking stoppage equipment

A strong magnetic field and balanced technology, applied in packaging, mechanical equipment, transportation and packaging, etc., can solve problems such as potential safety hazards, accidental attraction and collision, waste of people and money, and achieve the effect of eliminating leakage and strong and efficient magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

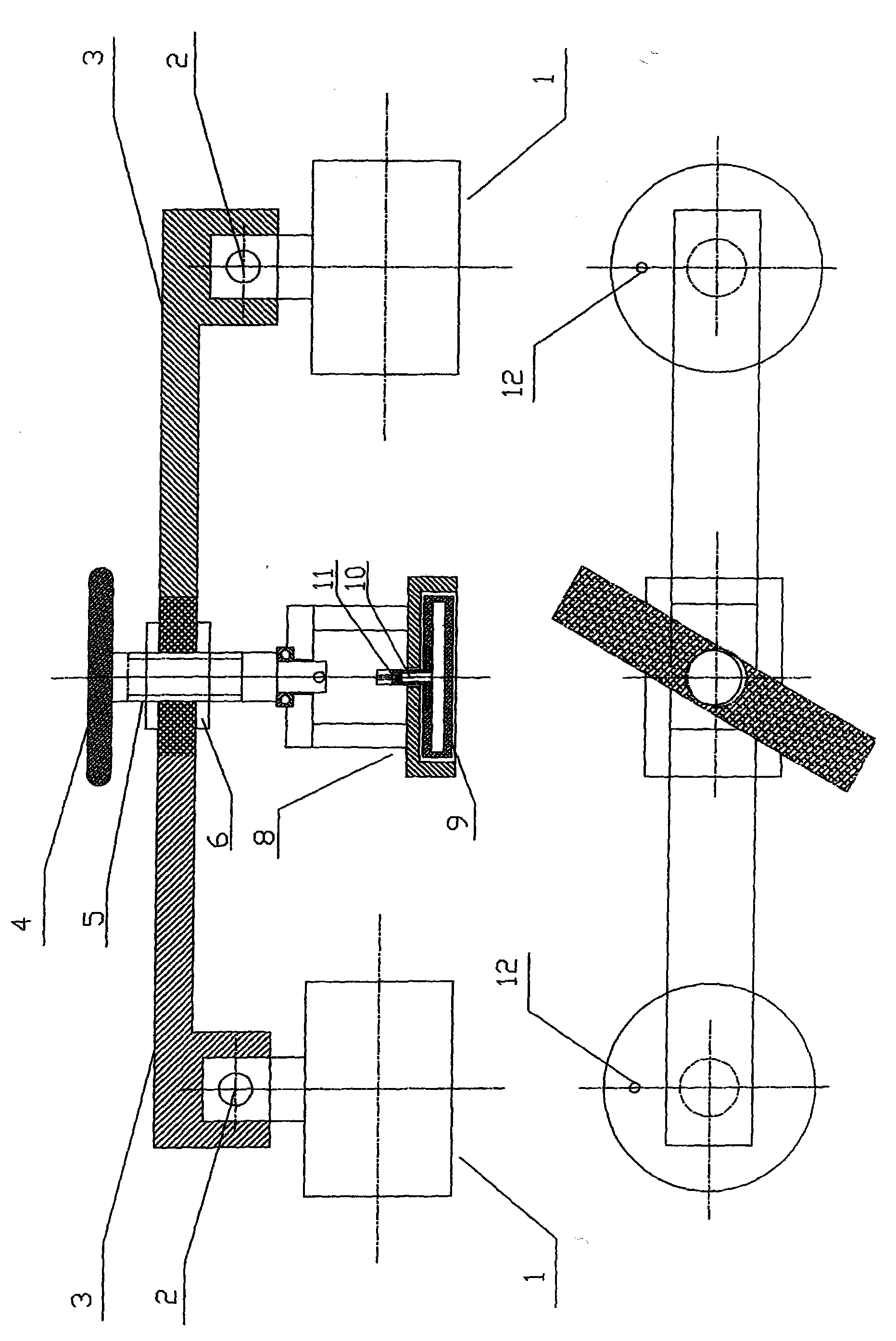

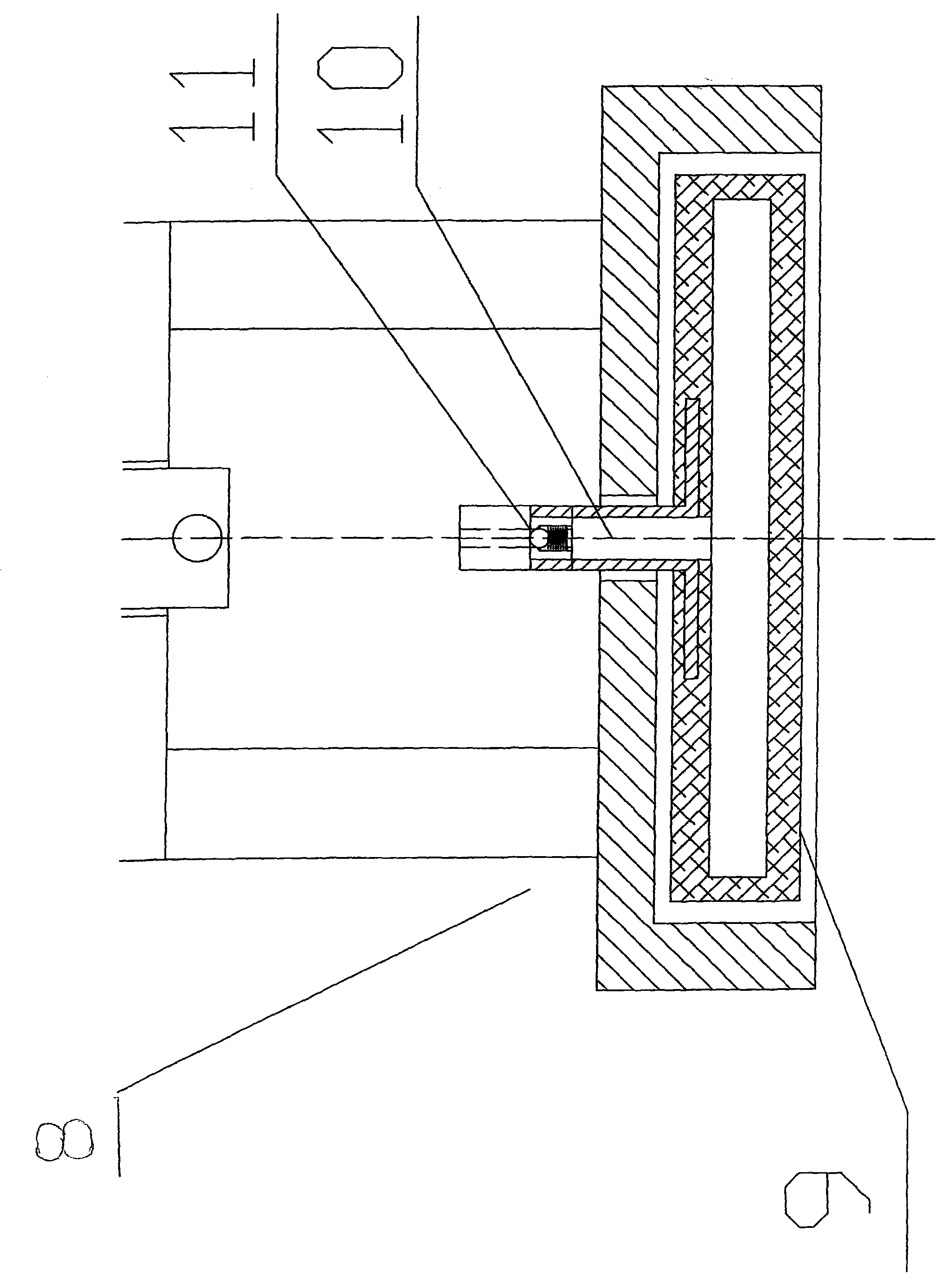

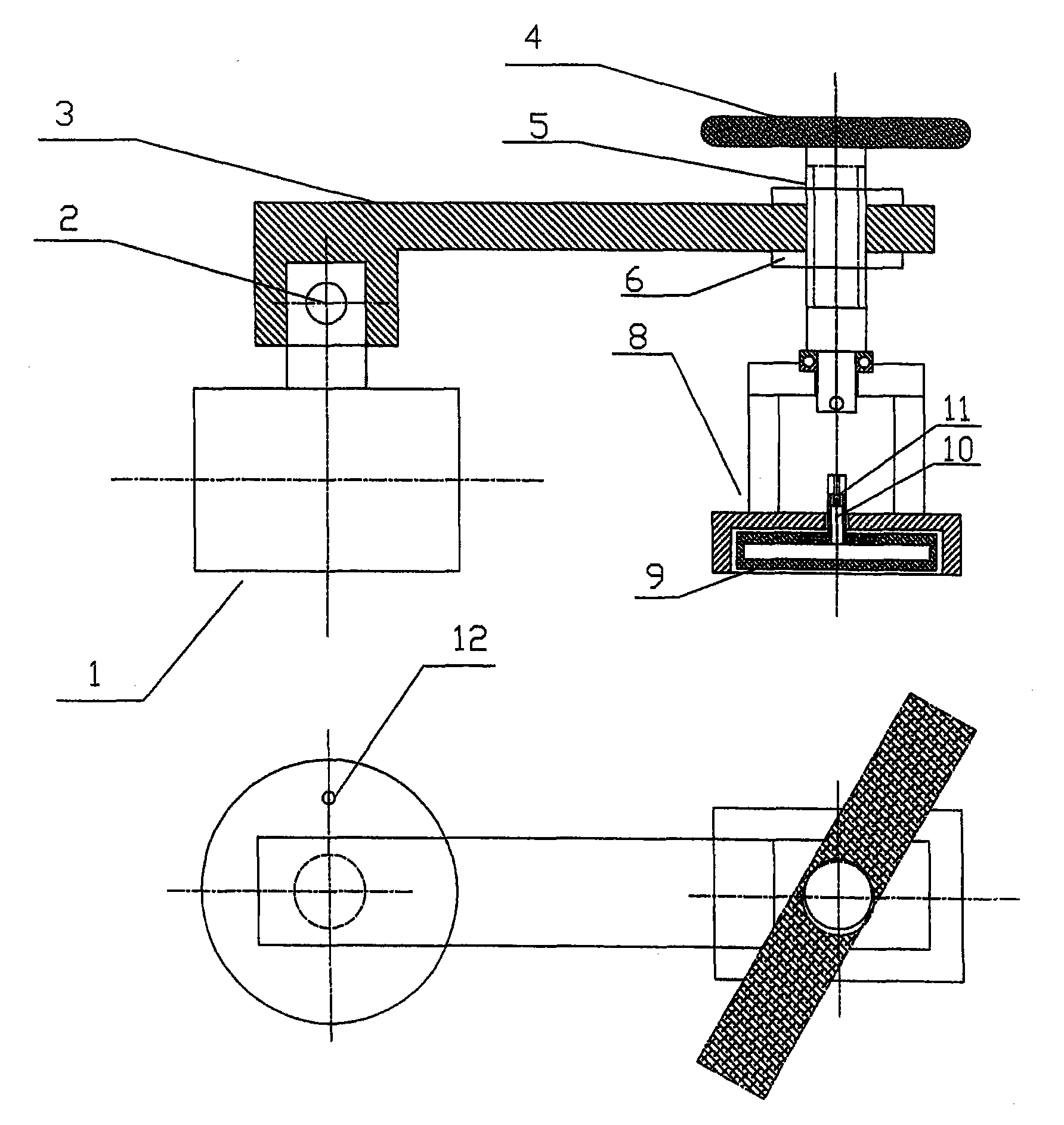

[0022] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. figure 1 , figure 2 , image 3 Three structural schematic diagrams of strong magnetic field positioning high-voltage balance plugging equipment for single, double, and three-body high-strength DC permanent magnet chuck combinations of the present invention are shown respectively. refer to figure 1 , figure 2 , image 3 The strong magnetic field positioning and high-voltage balance plugging equipment of the present invention, the three embodiments respectively include three consistent high-strength DC permanent magnet chucks 1 and corresponding matching three horizontal rods 3 and corresponding three uniform fixing pins 2 to form a high-strength DC permanent magnet. The magnetic chuck 1 is a geometric structure supported by a column; figure 1 As an example, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com