Hydraulically-driven full-vector water-jet propulsor spout

A water jet propulsion, full vector technology, applied in the direction of ship propulsion, propulsion components, ship components, etc., can solve the problems of large energy and power loss, limited adjustment ability, unfavorable high-speed adjustment, etc., to achieve small power loss and improve maneuverability The effect of flexibility and mobility, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

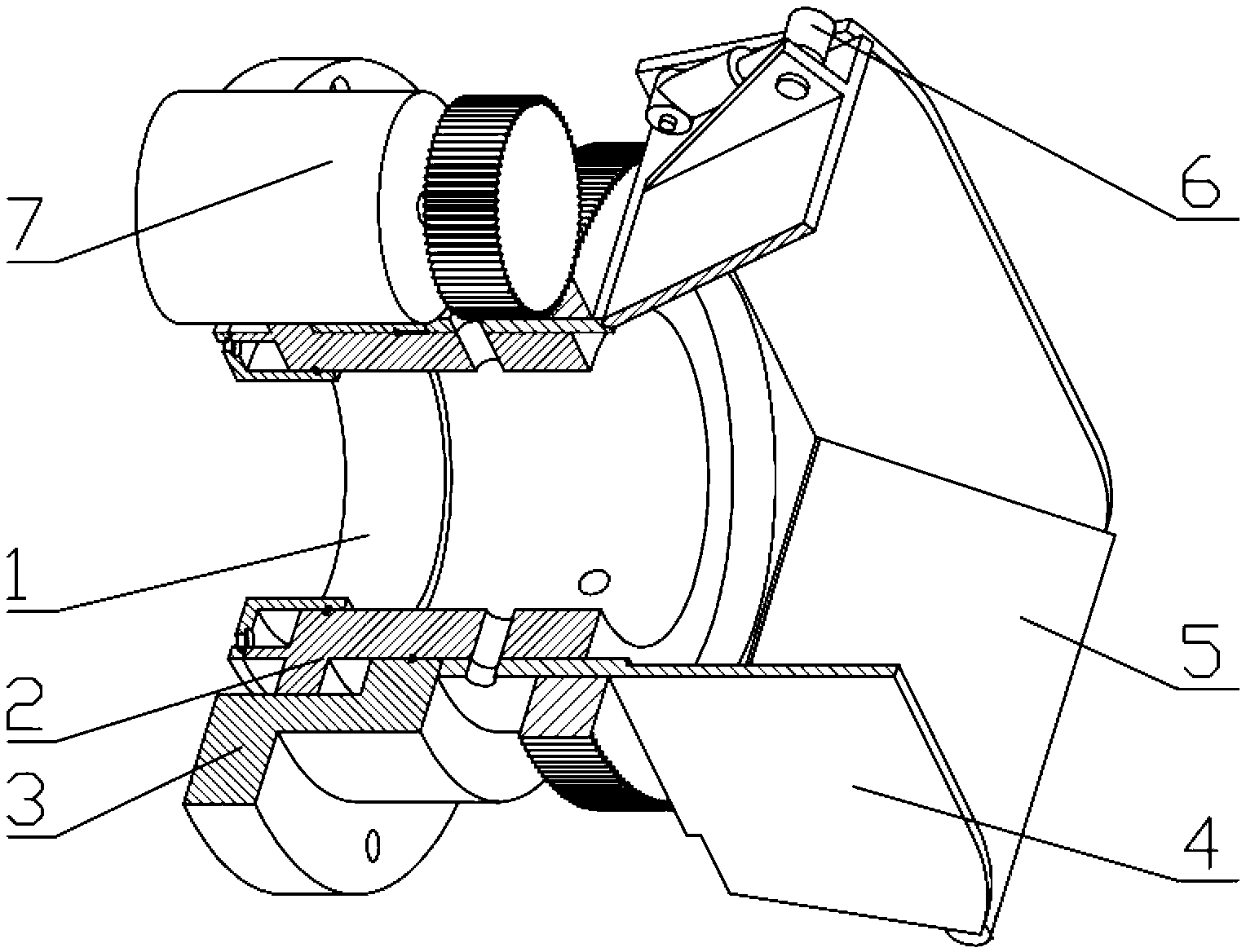

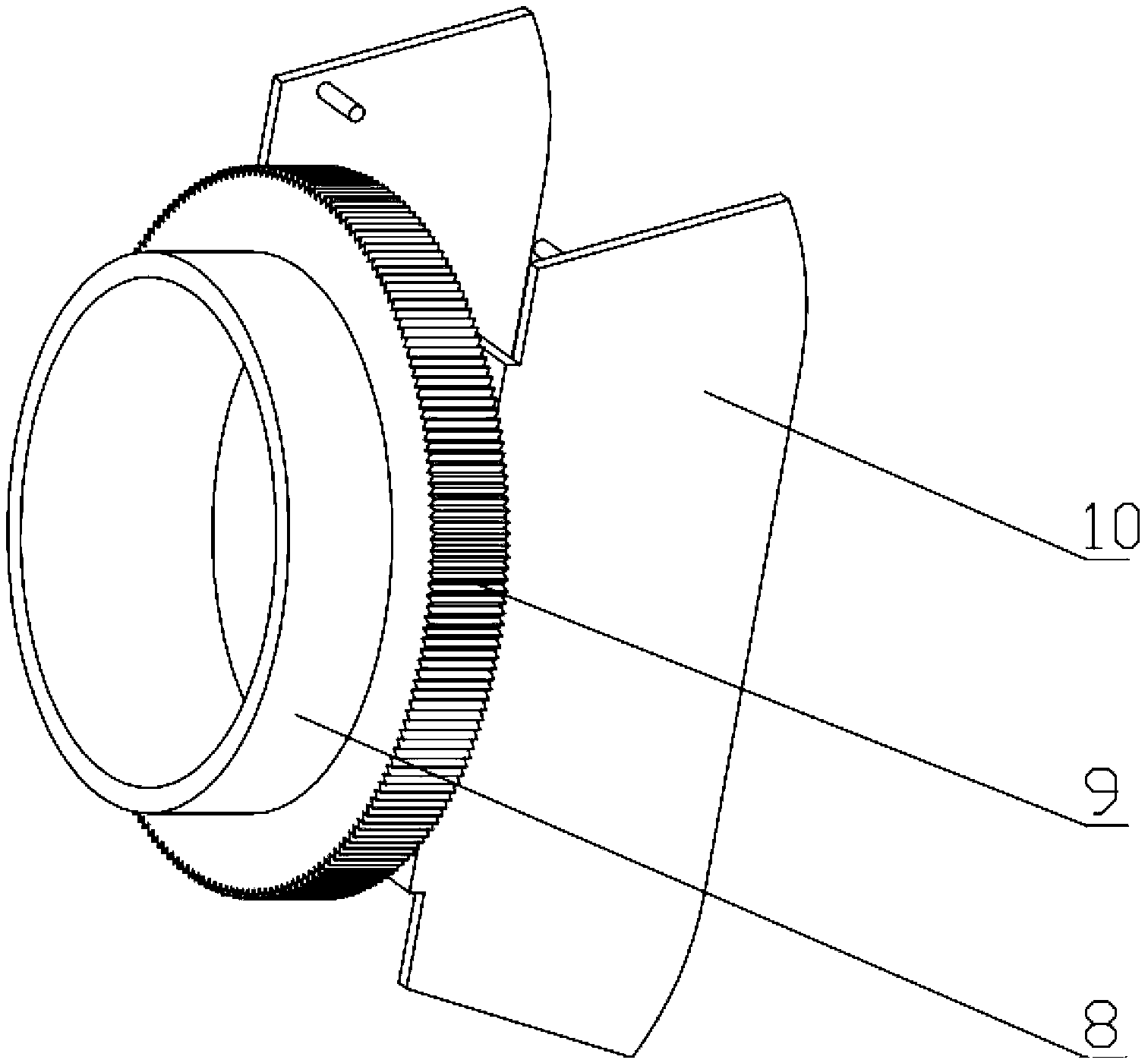

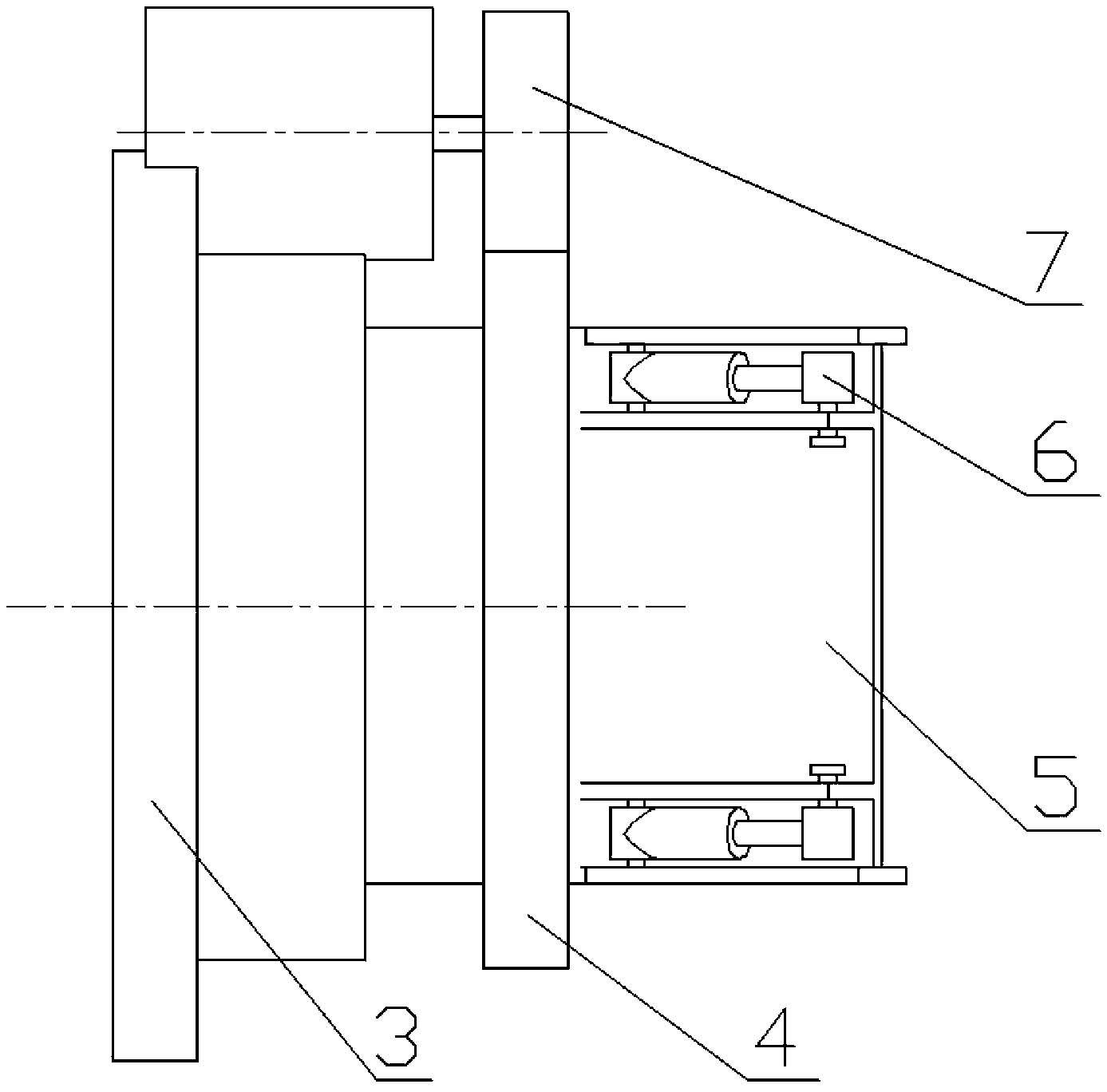

[0024] as attached figure 1 and 3 As shown, the present invention provides a hydraulically driven full-vector water jet propeller nozzle, including a rotating vane assembly 4, a swinging vane 5, a sealing base 1, a rotating support sleeve 2, a compression cover 3, a hydraulic motor 7 and a hydraulic Cylinder 6; the peripheral equipment is a controllable hydraulic pump system, which includes a hydraulic pump, a control system, a hydraulic valve and a hydraulic oil circuit, and the control system in the controllable hydraulic pump system controls the hydraulic pump according to the working conditions and is respectively a hydraulic motor 7 and a hydraulic cylinder 6 respectively provide the required power; figure 2 As shown, the rotating vane assembly 4 is composed of a transmission sleeve 8, a transmission ring gear 9 and a fixed vane 10; the sealing bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com