A cryogenic treatment method for improving the dimensional stability of gcr15 steel

A technology of dimensional stability and cryogenic treatment, applied in the field of cryogenic treatment to improve the dimensional stability of GCr15 steel, can solve the problems of unreported GCr15 steel material, reduced dimensional accuracy of shaft parts, affecting the machining accuracy of machine tools, etc. The whole process is controllable, the temperature changes uniformly, and the effect of avoiding excessive thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

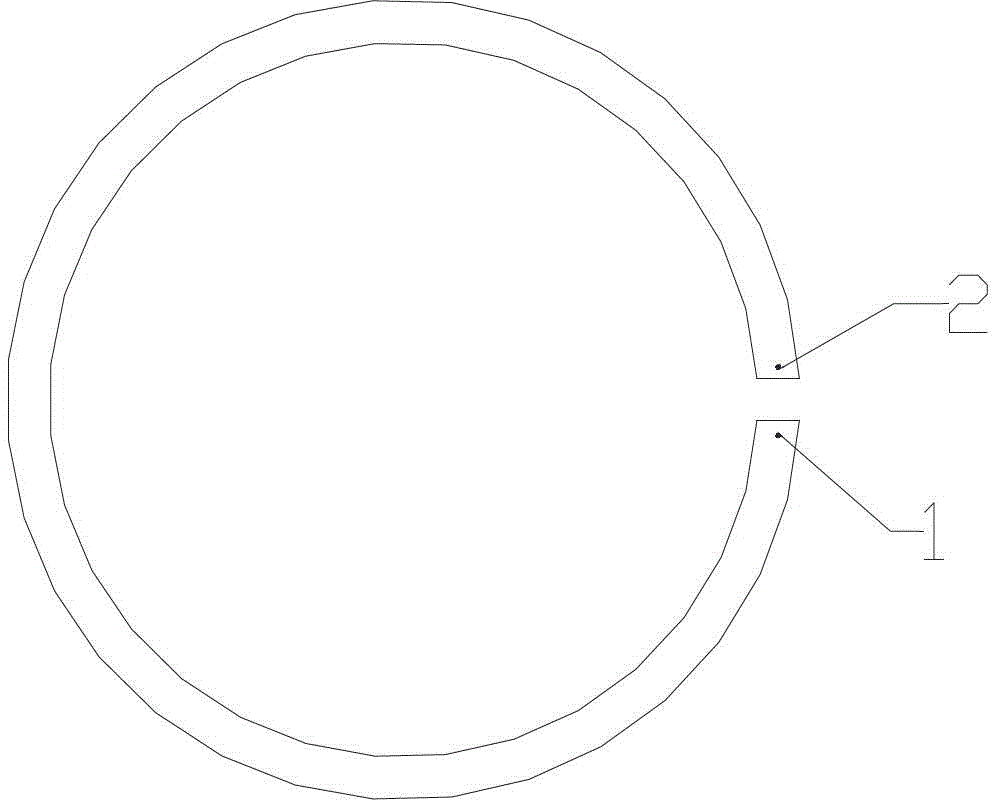

Image

Examples

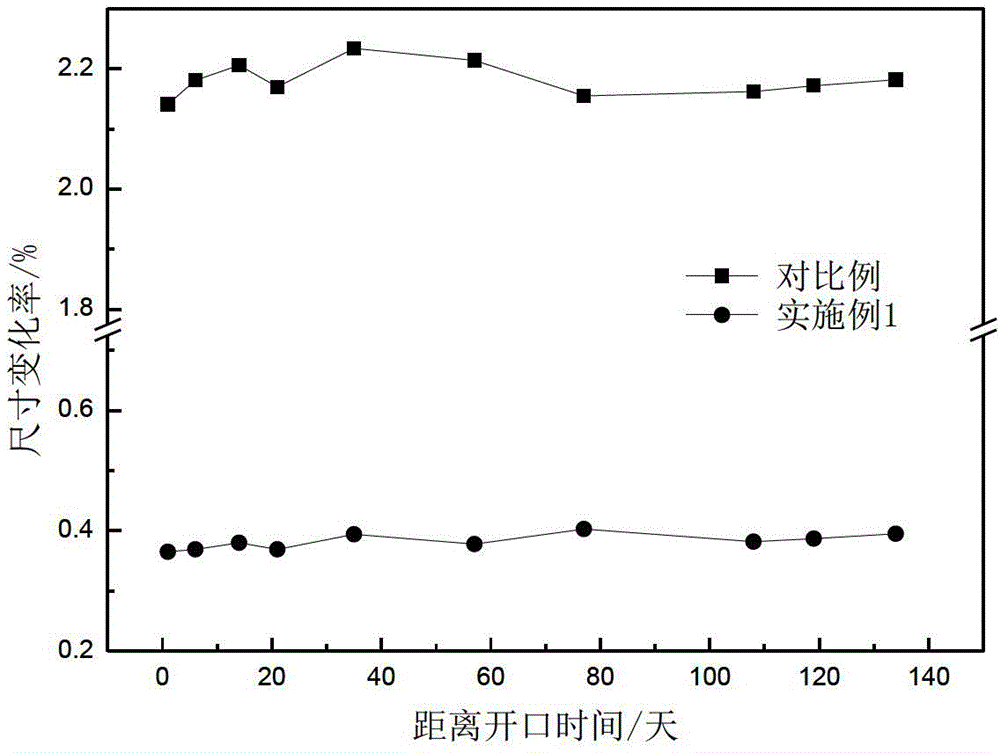

Embodiment 1

[0020] Cool the GCr15 material after quenching to -80°C at a rate of 2°C / min, and keep it for 0.5h; continue to cool it down to -190°C at a rate of 2°C / min, and keep it for 3h; The heating rate is heated to 20°C, and the heat preservation is 0.5h; after the heat preservation is completed, the normal tempering process is carried out.

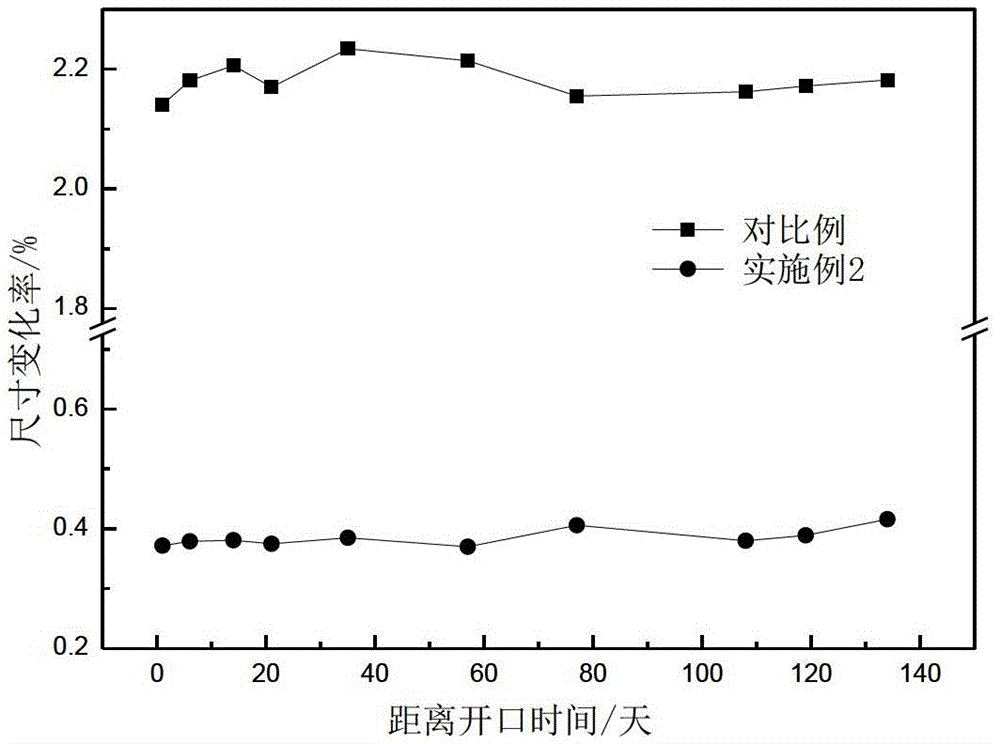

Embodiment 2

[0022] Cool the quenched GCr15 material to -100°C at a rate of 5°C / min, and keep it warm for 1h; continue to cool it down to -180°C at a rate of 5°C / min, and keep it warm for 2h; Heating at a rate of 20°C and holding for 1 hour; after the holding is over, normal tempering process is carried out.

Embodiment 3

[0024] Cool the quenched GCr15 material to -90°C at a rate of 3°C / min, and keep it warm for 0.5h; continue to cool it down to -185°C at a rate of 3°C / min, and keep it warm for 2.5h; The heating rate is heated to 20 ℃, and the heat preservation is 1h; after the heat preservation is completed, the normal tempering process is carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com