A method for manufacturing age-hardening thin strip continuous casting low-carbon micro-alloy high-strength steel strip

A technology of age hardening and manufacturing methods, applied in the field of thin strip continuous casting technology, can solve the problems of reducing production line advantages, increasing the floor area of thin strip continuous casting and rolling production lines, increasing investment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

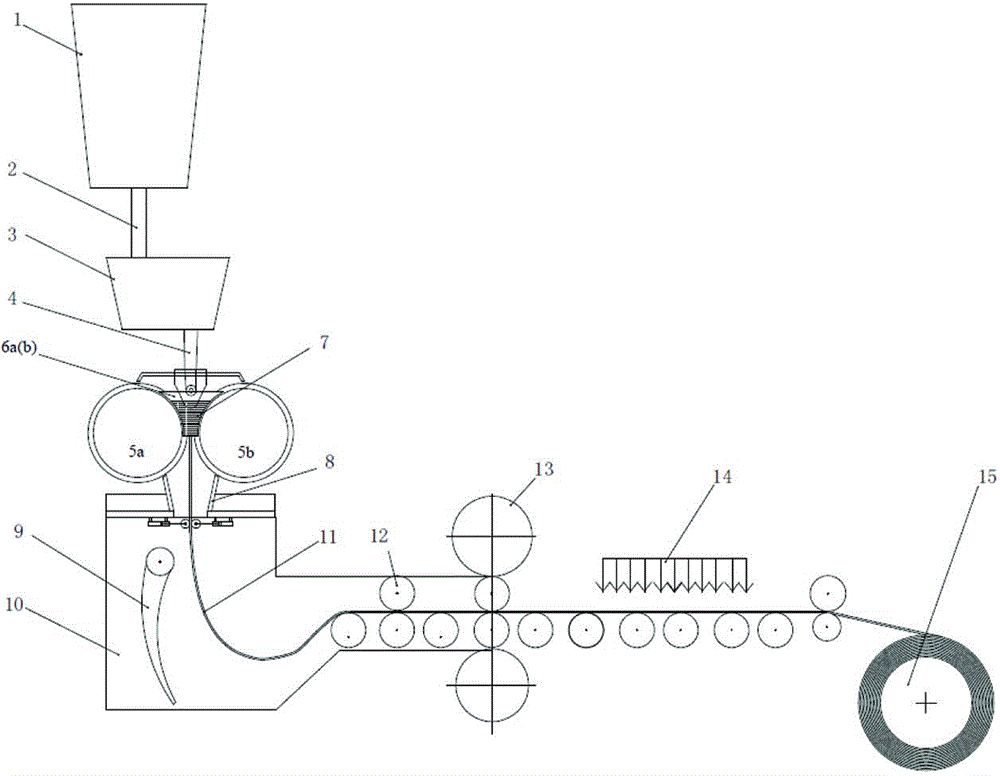

[0093] see figure 1 , the strip continuous casting process of the present invention is: the molten steel in the ladle 1 passes through the long nozzle 2, the tundish 3 and the submerged nozzle 4, and is poured into the water-cooled crystallization roller 5a, 5b and the side seal by two relative rotations. In the melting pool 7 formed by the plates 6a, 6b, a 1-5mm casting belt 11 is formed through the cooling of the water-cooled crystallization roller, and the casting belt passes through the secondary cooling device 8 in the airtight chamber 10 to control its cooling rate. Roller 12 sends cast strip to hot rolling mill 13, forms 0.5-3mm hot rolled strip after hot rolling, then passes through cooling device 14 three times, and then hot rolled strip enters coiler 15. After the steel coil is removed from the coiler, it is naturally cooled to room temperature.

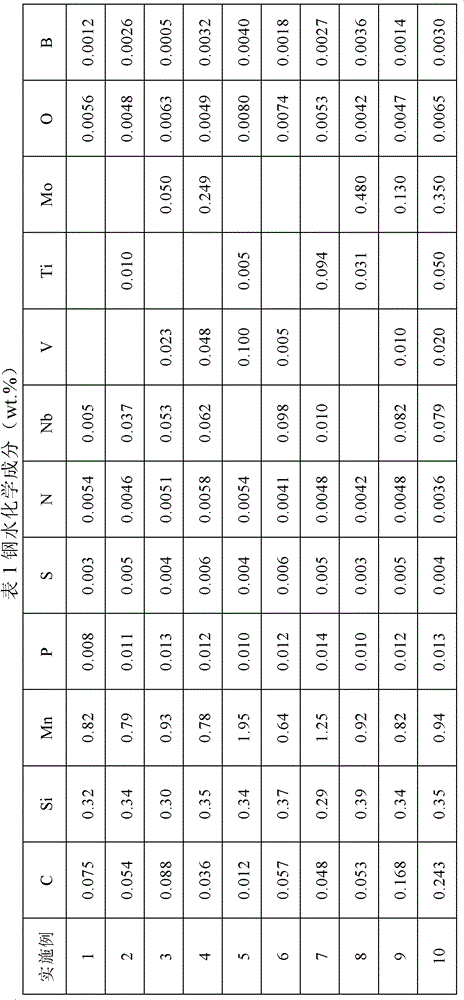

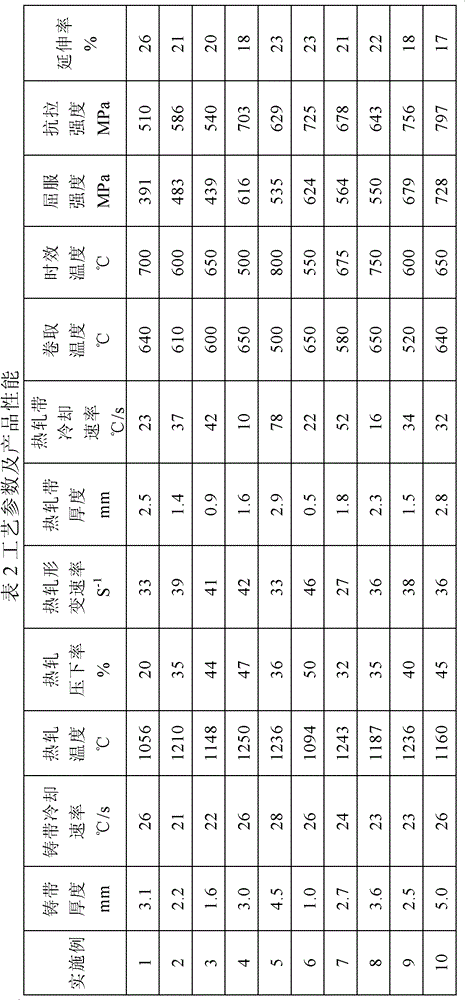

[0094] The molten steels of Examples 1-10 of the present invention were obtained by smelting in an electric furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com